Fresh

take on favorite country decor,

this birdhouse has features that won't

disappoint.

Slant "shake" roof shaping with overlays,

hex shaped

perch pole (with 3/8" wooden dowel inside),

low relief slat accents on sides,

low relief slat accents on sides,

chunky base rims.

Measures

approx. 7.75" tall x 5" wide x 4.25" deep .

Interior support triangle

roof "beam", hull collar & tray

make the structure sturdy for

long-term storage and display.

Optional separate designs can convert it

into a patriotic decoration: "Freedom Layered Banner"

and

"Patriotic Shield Swag"

(optional front hull and accent overlay

included

with punch holes to attach Swag).

(Shield assembly begins in Step 2.

Birdhouse assembly resumes in Step 8.)

(Shield assembly begins in Step 2.

Birdhouse assembly resumes in Step 8.)

ASSEMBLY: 1. Identify and cut the shapes:

A & B hull front/side and back/side panels

(NOTE: choose FRONT panel with or without

shield decoration punch holes as preferred.)

C roof "beam" triangle box shape

D circle opening reinforcement build up rings (4-5)

E hull reinforcement interior panel

F hull bottom reinforcement tray

G hull bottom concealing cover

H perch post

I post collar strips (help hold post in place)

J hull front accent shape

K hull sides accent shapes (2)

Not shown: hull back accent shape

L optional side accent raised panels (6 sets)

M bottom rim shape

N rim bottom concealment cover

O roof base with slots

P shake roof with tabs

Q roof accent shapes (2 sets)

2. If decorating the birdhouse front with

the Freedom banner or stars and stripes shield,

these are the shapes that are used:

A freedom "word cut" with bottom,

mid & top banner layers

B shield base shape

C & D cascade shapes

E shield assembly silhouette

F stars panel for contrast show-thru

G stars panel overlay

H stripes panel base silhouette

I stripes overlay (trim to size of H)

3. Position and attach stars face overlay

onto show-thru liner.

4. Position stripes overlay centered on top of shield basesilhouette . . .

. . . so that header is above top straight edge,

then attach stripe backsides to shield where both touch.

When glue is dry, trim away excess stripes overlay

so that cut edges are even with shield shape.

NOTE: it is easier to see the shield edge to follewwhen working from the back.

5. Position the stars panel at top of shield assembly silhouette

and the stripes panel on bottom.

NOTE: it is possible to leave off the assembly silhouette

and simply place the two components directly onto

the offset shield base shape, if desired.

6. Position and attach the shield assembly

onto the offset shield base.

7. Add the side cascade shapes (left and right)

behind the shield layer

with punch holes lined up, then add mini brads

through holes or place studs over holes.

8. Prepare front (shown) and back hull panels by

bending back at edges of panels, also flange tabs.

9. Position hull shapes together with straight side edgeof one overlapping the side flange or the other,

bottom edges aligned, and glue side seam #1.

10. Prepare the reinforcement ring build up for

round opening by layering and gluing together

the ring shapes, taking care that all interior

cut edges line up as precisely as possible.

NOTE: it will be helpful to use a flat weight

(here and with other stacked and layered

built-up components) placed on top of the stack

until the unit is completely dried, to keep

shape flatted and avoid warping.

11. On the backside of the front hull, position

the ring build up stack to align with circle cutout,

and glue in place. (Use flat weight if possible.)

12. Prepare to add the hull accent side and front

(and back) accent panels by identifying the slat

build up alignment guide marks on the top

and near bottom of the side accent panels.

Position and attach accent panels to hull assembly.

and attaching the 4-5 strips exactly on top of

each other, taking care to align all edges as

precisely as possible. Prepare 6 total slats.

NOTE: the sample project shown here has a contrast

top strip layer which is also added to the stack.

14. Position and attach three slat units

on top of the side accent panels,

aligned at top of accent shape, using

guide marks. Flatten with weights if possible

during drying.

NOTE: the strips have been shortened in

the final cut file to eliminate interference

with bottom rim.

15. Form the hull into a tube to bring straight side

edge to overlap opposite flange, and complete

side seam #2.

(NOTE the symmetry of the hull will permit

it to be laid flat to apply pressure along the seam

while attaching.

16. Prepare the beam box shape by bending

back on all perforation lines.

17. Form the beam shape into a triangular tube

to bring straight front edge to overlap opposite

flange to perforation line, and glue seam.

Fold side triangle wall tabs inward, then tuck

into the end openings and glue in place.

Complete both ends.

18. Prepare to attach the beam to gable lineof hull assembly by applying glue to ends . . .

. . . and also to hull flange areas that

will overlap beam, then position between

hull front and back walls at crest, and

glue in place.

19. Apply glue to the hull flange faces on

right side, and right half of beam, then . . .

. . . bend roof panel over into position to

attach securely, taking care to line up

roof panel edges with hull gable edges.

20. Repeat for left side.

21. Prepare the perch post shape by bending back

on all perforation lines, flange, hex and triangle tabs.

22. Use a 3/8" wooden dowel as a press-against

form. Wrap the post shape around the dowel,

overlapping the straight long side edge over

the opposite flange perforation line, and glue

in place securely, moving finger pressure

along the length of the seam to ensure even joining.

23. With dowel inserted and aligned at hex baseon one end, mark opposite end at hex base edge

to determine cutting length, then cut dowel to size.

24. Bend tabs inward, and . . .

hex end over top of tabs, and glue in place.

Complete both ends.

25. Prepare the attachment collar shapes (2)

by bending back on all 5 tiny perf cuts.

26. Position one attachment collar over "back"end of post, wrap so that perf bends align

with post shape angles, and glue in place.

27. Insert non-collared end through post opening

on hull back, push through hull interior, then

insert through front opening and push through until

collar stops the post.

Apply glue to collar inside surface, then reach

second collar shape inside hull to wrap around

and attach to post as close as possible to

the front hull wall.

28. Prepare reinforcement "collar" shapes by

bending side walls and flanges back.

29. Form each into a tray shape to join side wallends to opposite tabs. Complete all four corners

of each tray.

30. Apply glue to side walls and

insert the interior reinforcement into

the bottom of the hull, then . . .

. . . push upward to a position just below post

and shield attachment punch holes,

and glue in place.

31. Insert the bottom tray into hull opening, then . . .

. . . push in until bottom is flush with wall base edges.

32. Position and attach the bottom cover.

33. Prepare the base rim shape by bending back

on all perforation lines, except bend edge tabs

forward and rounded side end tabs forward.

Identify the miter angle cut on the rim top panels

that will overlap side walls, as indicated by

pointing finger.

This image identifies the rounded end tabsof side walls . . .

. . . which are bent forward to eventually

tuck behind front or back rim walls.

34. Bend each side wall inward to form a tubeas edge tabs are inserted into corresponding slots.

On backside, bend tabs toward center

and glue in place to rim base underside.

Bend end square tabs inward, as well as

rounded inside wall end tabs as shown.

35. Bend front and back rims toward center

in similar manner, taking care during the process

that the square and rounded end tabs insert

inside the front or back tube

(apply dabs of adhesive first), with miter angled

edge overlapping side rim wall, as tabs are

inserted into slots as for side walls.

Add a dab of glue under the miter edge . . . . . . then push front or back wall completely

into "tube" position, and glue tabs in place on back

as for side walls.

36. To assist attachment of side rim end tabs,

insert a narrow rod tool end into into

the corner openings to push and direct tabs behind

corresponding interior wall surfaces until secure.

37. Position and attach rim bottom concealing cover.

push fully down, and glue in place.

39. Prepare the roof base shape be bending back

on center ridge perforation lines.

40. Prepare shake roof overlay by bending back

(mountain folds) at center lines, also on end flanges,

and on two other panel lines as shown in following

diagram.

Bend forward (valley folds) near tabs.

with center ridge lines aligned, then insert upper row tabs

of overlay into corresponding slots in base.

On underside, bend tabs toward and glue in place.

42. Insert bottom row tabs into corresponding

slots, bend and glue in place as before.

42. Bend and wrap bottom flange of overlayaround base bottom edge, with edge at flange perf line,

and glue in place.

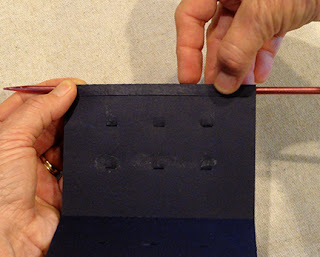

NOTE it will be helpful to insert a narrow rod-like

tool such as this knitting needle into the space

behind the flange to provide a "press-against"

surface to complete the seam.

43. Separate the roof base and overlay as muchas possible at ridge line to apply adhesive

to between along perforation line of one shape

or the other. Push together with ridge perfs

aligned, and apply pressure until the joint is secure.

44. Position and attach the concealing accent strips

to each roof level, with inner edge aligned along

tab perforation lines.

NOTE that widest strip is on top level.

45. Apply glue to the hull roof panels,then position (centered front to back) roof unit

over the hull and attach in place.

46. Decorate as desired using one of several

layered banner designs (Freedom shown;

America, Liberty also available in size that fits)

and the stars and stripes shield.

Use dimensional foam squares under banner

if desired.

Here is completed project,

sturdy enough to display, then store until

next appropriate holiday for years to come.

No comments:

Post a Comment