Realistic replica cowboy hat has recessed

contours

on front crown sides and top.

Front decoration includes

a shell shaped

medallion and side flourishes.

A fun decorative piece, this hat

can be embellished for Fourth of July, rodeo theme party,

part of cowboy

Christmas tree decor, and more.

One version shows front embellished with feathers

cluster

behind the medallion, with studs attached over hole punches.

ASSEMBLY

1. Identify and cut the shapes:

A main crown shape

B crown top contour inset

C right side contour inset

D left side contour inset

E brim

F back rim half

G front rim half

H hat band front half

I hat band back half

J front decoration shapes

2. (No image) Prepare the crown main shape by folding on perforations: a) fold front and back portions vertical perforations slightly back to form the crown into tube shape; b) fold the top inset opening crown lines down, tabs upward; c) fold side inset contour lines up. (See more detail about folding by studying images as construction proceeds.)

3. Prepare the top inset shape by folding on perf lines as shown here.

4. Position the top insert into the crown top opening with wide and narrow ends corresponding to opening wide and narrow ends.

Align insert straight ends at end tab perforation lines, center,

and glue one end . . .

. . . then align, adjust and attach the other end.

5. Push the contour into place as tabs on both insert and crown opening are positioned and adjusted to over-lap or slide under appropriate edges to arrange as shown in the image.

From the backside apply adhesive under the tabs, then re-position and hold each in place until insert is secure along all seams.

6. Adjust crown to bring back panel upper angled edge to line up with straight edge over tab and at perforation line.

Repeat for second upper angle seam.

7. Prepare side contour insets by folding tabs upward slightly.

Position left or right side into the side opening so that the tiny symbol cutouts correspond (circle punches shown here).

8. Slide the top tab under the straight edge of the opening, align edge at perf line and attach in place.

9. Bend the side straight edges of crown opening into place to correspond to the inset side angle perforation line, and glue tab in place underneath.

Repeat for the second side edge of insert and crown opening.

Complete the joining of both left and right insets.

10. Fold the crown to align the front upper angle straight edge into place at the contour edge perforation line and glue in place.

Repeat for both left and right sides.

11. Bring side straight edge into alignment with opposite side tab perforation line, then join while at the same time aligning and joining the top of the crown side panel edge to the bottom inset tab.

Repeat for both sides of the crown assembly.

12. Prepare the brim by attaching the rim halves to the upper (face) surface of the brim.

NOTE that there is a tiny hash cut at the center back of the brim and rim pieces.

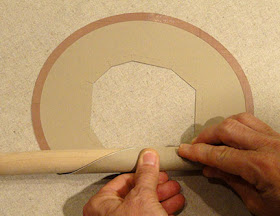

13. Before rim attachment adhesive is completely dry when it will be more pliable, add some curl to the sides of the brim for the realistic cowboy hat appearance.

One way to do this is to use a fairly good size diameter dowel or broomstick handle, or equivalent, then begin at brim edge to slowly and carefully roll the brim around the dowel. Repeat, adding slightly more pressure, and holding in place longer to increase the curl to the desired shape.

14. Fold the opening tabs upward.

15. Slide the crown in place over the brim opening, with the tabs inside the crown.

Line up the center front tab with the center front crown panel, adjust for centering,

then . . .

. . . glue tab in place and apply pressure until secure.

16. Line up and attach the center back tab in similar fashion. Line up each remaining brim tab with corresponding edges of crown and glue in place.

17. Prepare the hat band shapes by bending back slightly on each of the vertical perforation lines.

(NOTE the longer band half is front band.)

18. Overlap the side edges with front band on top, and attach by inserting a brad fastener through punch holes on both sides.

19. Orient the hat band so that band front/back corresponds with front and back of hat assembly. Slip band over the crown and slide down fully into place.

Apply a little adhesive between band and crown front and back, and otherwise as desired. (Band will fit snugly without adhesive.)

20. Assemble front decoration shell concho medallion and side swirls sections.

21. Center and attach shell concho on front panel of hat band. Attach side swirls by placing each on the front side panels of hatband, pushing in behind shell medallion as far as possible to that they give the appearance of being connected.

Apply pressure to the back portion of swirl flourish to help it follow the crown contour and attach completely.

Here is the completed 3d cowboy hat.

such as the feathers cluster pictured in the thumbnail,

you may wish to add some curl to the concho medallion

to accommodate the bulk of the embellishment

prior to attaching it in place.

Attach feathers at center front

over hat band,

then apply adhesive to the underside

of medallion where it will contact the hat band

or crown, then glue in place.

(NOTE: it may be helpful to use

hot glue to attach feather-style embellishments

and medallion edges.

Here is the finished, feather-embellished hat.