Perfect boxes to hold daily scriptures, thoughts

of encouragement,

collected birthday messages, wedding wishes, recipes and more.

Each box is

composed of two shapes and includes

latch bottom

and tuck top that holds standard 3x5

index cards snugly inside,

viewable through windows.

Circle window box (1.5" deep) has teardrop and scallop layers

"icing" trim,

with varied size flowers with leaf sprigs

to attach with mini brads to box.

Oval window box (2" deep; no-window version 1" deep)

has layered "icing" trim alone.

Box side wall accent shapes are included

to decorate

with favorite paper selection.

Also includes a corner punch 3x5 card that

can be connected

with short ball chain, tucked inside the assembled box.

Or

use the "Card Index Flip Cards" varied designs

to create your own

matching card inserts.

Measures 1.5" deep, just larger than 3" wide

x 5" long

(can hold around 90 cards of 65 lb weight).

ASSEMBLY: 1. Identify and cut the shapes:

CIRCLE WINDOW BOX

A main box hull with lid B side wall accents

C front box hull D accent shapes

E contrast underlay F clear window panel

G contrast "icing" accent ring

H "icing" overlay ring (matches box hull)

I leaf sprigs (2) and flower decorations

OVAL WINDOW BOX

A main box hull with lid B side & back wall accents

C main box front hull D side & back wall accents

E oval opening "icing" contrast and overlay

F index card with rounded edges and punch hole

(also included in the circle window box file)

under the front panel, face surface upward

(clear panel as bottom layer) . . .

. . . match circle opening

edges of each, and attach in place.

the contrast ring, match inner opening edges

exactly, and adjust so that the resulting

reveal of contrast is a wavy line, not just a scallop.

Glue the rings together.

9. Position the ring on the front of the box

matching the inner circle openings, and also

rotating the accent rings so that the lid cutout

tear drops fall between the arches of accent.

window opening edges.

. . . the fold side panels inward . . .

19. Prepare a stack of index card shapes using

the one included in each of the box's cut file.

Or, use the Card Index Flip Card designs

to "Print & Cut" (tutorial link HERE )

specialized cards to suit

the purpose of the gift box: Scripture,

Recipe, Sentiments, Passages, plain or simply lined.

Thread a short length of ball/bracket link chain

through the corner hole to keep them organized

and handy to refer to.

A main box hull with lid B side wall accents

C front box hull D accent shapes

E contrast underlay F clear window panel

G contrast "icing" accent ring

H "icing" overlay ring (matches box hull)

I leaf sprigs (2) and flower decorations

A main box hull with lid B side & back wall accents

C main box front hull D side & back wall accents

E oval opening "icing" contrast and overlay

F index card with rounded edges and punch hole

(also included in the circle window box file)

(Circle window box assembly is shown first;

oval window box will follow)

2. Prepare the hull shapes by bending back on

all wall, panel, flange and tab perforation lines.

3. Position and join the back and front hull shapes

along one side seam by overlapping the straight

side edge over the corresponding side flange tab

to perforation line, adjusting to make top and bottom

wall edges of each shape align, then glue together.

3A. Position and attach the side panel accent shapes

offset by .1 within the side, front and

back wall panel edges.

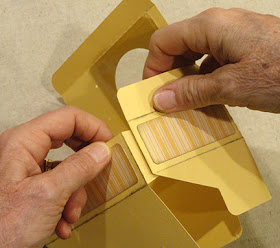

4. Prepare the clear window liner shape by

applying clear double stick tape along the top surface

edges. Kool Tak 1/8" tape shown here was used

on the sample projects.

5. Position and attach clear panel to the

underside of the contrast panel, matching edges

and single punch hole.

6. Position the contrast underlay panel under the front panel, face surface upward

(clear panel as bottom layer) . . .

. . . match circle opening

edges of each, and attach in place.

7. Form the box hull into a tube to bring the remaining

side edge and tab together to complete the final

side seam.

8. Position the narrower top "icing" ring overthe contrast ring, match inner opening edges

exactly, and adjust so that the resulting

reveal of contrast is a wavy line, not just a scallop.

Glue the rings together.

9. Position the ring on the front of the box

matching the inner circle openings, and also

rotating the accent rings so that the lid cutout

tear drops fall between the arches of accent.

10 Position the leaf sprigs as shown below,

with the end punch holes aligned at the middle

hole of the box lid, then attach in place.

11. Position smaller flowers over the top and

bottom punch holes and attach in place

around punch hole.

12. Add some curl to the petals of the larger

top blossom, then layer with the largest flower

over the center hole and attach in place.

Add contrast mini brads through punch holes

as flower centers.

13. To close the box, expand the hull into

its tube form, bend the 'U' front flap inward . . .

. . . then fold the side flaps inward . . .

. . . then fold the back 'tab' flap inward, and

continue to press slightly upward toward

the interior of the box until the tab inserts

into the 'U' shape slot.

Then re-position the bottom flaps so they

are flat and perpendicular to box sides.

Here is the completed circle window box.

OVAL WINDOW BOX

14. Prepare the two hull shapes by bending

back on all panel, wall and tab perforation lines.

Join the side seam as described in step 3.

Position and attach the side, front and

back wall accent shapes to corresponding

hull panel spaces.

15. Layer the oval window "icing" accent shapes

with interior edges aligned as precisely as possible,

with reveal of contrast accent forming a wavy line,

and glue together.

16. Position and attach to box lid, matchingwindow opening edges.

17. Prepare, position and attach the clear

window panel behind the window opening

of lid panel . . .

. . . taking care to center it over the window opening.

18. To close the box, bend front panel inward . . . . . . the fold side panels inward . . .

. . . then fold back panel inward until tab

slots into the slot space, then readjust panels

to be flat as box bottom.

Here is the completed oval window box.19. Prepare a stack of index card shapes using

the one included in each of the box's cut file.

Or, use the Card Index Flip Card designs

to "Print & Cut" (tutorial link HERE )

specialized cards to suit

the purpose of the gift box: Scripture,

Recipe, Sentiments, Passages, plain or simply lined.

Thread a short length of ball/bracket link chain

through the corner hole to keep them organized

and handy to refer to.