Stylized sunflower bloom is built with fancy petals

shaped by

curling and supported by a shallow “cup” behind,

with flattened

dome, front grille accent overlay in center.

Cubic card stock stem is stiffened

with .25” wooden

cut-to-size dowel inside, with attached layered leaves

(with embossed

veining), inserted into a three-tiered

platform stand with angled checker

accent panels

and thickened scallop edge base.

(Since stem can stay in place for display without

gluing, sunflower display can be conveniently stored

until next season's use.)

Two stem shape lengths included,

to create a paired ensemble for a summer or autumn display.

Tallest version

measures approx. 13.375”.

Platform base is 4.2” x 4.2”.

Blossom measures

approx. 4.75” across (when shaped).

ASSEMBLY: 1. Identify and cut the shapes:

A petals disc B blossom shaper cup with separate wall arc

C blossom dome walls arcs (2)

D dome floor disc E dome top disc with finger openings

F dome top solid disc and grille overlay

G blossom cup back panel H stem post

I leaves for embossing

J leaf base with stem K leaf reinforcement

L veins embossing form

M base scalloped squares to layer for thickness (4-5)

N base scalloped square top layer with column opening

O post collar 4-5 shapes to layer for thickness

P platform base tier 1 Q tier 2 angled platform

R & S checker base and accents (4 each)

T column hull U column post collar (4-5 shapes to layer)

to be drying as other assembly progresses:

A) layer and glue together scalloped square bases,

taking special care - here and throughout - to align

a heavy flat object on top, such as a wooden plank or

the thick book shown here, until fully dried. This will

help minimize curling or warping when using liquid adhesive.

B) layer and glue together each set of post collar shapes,

B) layer and glue together each set of post collar shapes,

then press under a flat weight until dried.

The center of the petals disc should begin to resemble

NOTE: The petals and cup shapes originally included slots

for attachment to dome with tabs. Final design was

changed to remove slots and tabs;

some images will include them.

3. Prepare the petals by shaping with a narrow rod tool

adding forward curl at base of each petal, then . . .

. . . adding back curl at middle to tip of each petal.The center of the petals disc should begin to resemble

a cup, that will later accept the blossom dome.

Apply distress ink to add color/shading at the base

arch strip between segments, and bending back

NOTE: it may be helpful to "pinch" fold at that tab

the arc free end tab under the opposite straight

boxing end edge and join the seam.

adjusting to make sure that boxing edge and perforation

edges align precisely, and attach in place at each tab.

8. Position petals shape over inside of shaper cup . . .

8. Position petals shape over inside of shaper cup . . .

. . . using center hole to align both shapes, with each petal

aligning with center of one of the fourteen disc facets,

and glue in place.

Apply gentle pressure to shape the petals with evenmore definition at cup edge, pressing all around.

To help with the attachment of the two components,

consider placing something columnar-shaped inside

the petals "cup" until glue dries, such as the bottom

of a full commercial water bottle of matched diameter.

slightly at each segment perforation, also bending top

straight edge of one arch over the corresponding tab

to join first one side seam, then the other.

11. Bend bottom tabs outward, then position the disc inside

11. Bend bottom tabs outward, then position the disc inside

tabs, apply adhesive to inward face of tabs, then . . .

rotating so that arch segments align each disc edges

to insert finger- of thumb-tip into dome to apply

pressure all around until . . .

. . . tabs are completely attached.

(Remember, the tabs on bottom disc have been eliminated.)

12. Bend top dome tabs inward to perpendicular,then apply glue to tabs. Position the "hollow"

top panel, adjust for segment and panel facets adjustment,

and attach. Insert fingertips into openings to "pinch"

the solid top panel disc. Then position and attach

to the hollow top panel, matching edges precisely.

14. Prepare tier 1 platform by bending back on all

14. Prepare tier 1 platform by bending back on all

perforations for center panel, walls, corner tabs;

edge over inward-bent corner tabs, and join

to tier 1.

the checker cutouts on the contrast base trapezoids,

corresponding trapezoid area, centering with narrow

each angled side seam.

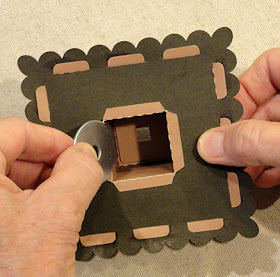

20. Prepare the column shape by bending back on

perforation lines for side wall panels, forward on

bottom tabs . . .

. . . bending back on "lid" edge perforation, thento apply finger tip pressure along the seam edge.

22. Position and attach the two post collar stacks:

one is placed on the backside of the column "lid",

and the other on the top of the base scalloped square.

taking special care that the post square openings are

as precisely aligned as possible.

Press under a flat weight until thoroughly attached.

23. Prepare to bend the column "lid" into place by

applying glue to the wall between column and lid,

wall onto inside of tube, also . . .

of the long perforation lines for skinny panels

side edge across the opposite flange to perforation line.

Flatten the tube on work surface to apply fingertip

pressure all along the seam until completely attached.

26. Re-form the tube to insert the 1/4" wooden dowel

inside . . .

with non-tabbed end of tube.

top edge (NOT tabs) with fine pencil.

Saw the dowel to that length.

27. Reposition the dowel inside the tube so that tube

and dowel ends align, adding adhesive to attach

in place.

28. Bend the top tab down into position to "cap"

the tube and glue in place to top of dowel.

NOTE: shaped tab with two holes should still extend

up from post.

29. Position the post onto front of back disc toalign holes, with adhesive on back of holes tab,

AND also on post underside wall that can attach

to disc. NOTE: use dash guide marks to help align post.

Add small decorative brads through the two holes,

and press prongs as flat as possible on underside.

30. If desired, emboss the veining details onto leaf.

A) Position the vein form onto the BACKSIDE

of leaf, and hold in place.

B) Use a large ball stylus to press the veins location

into the leaf backside.

C) Invert the leaf with form underneath, then

use the same tool to press the vein lines down

into the leaf.

D) For more definition, use a smaller ball stylusto carefully trace around edges of vein depressions.

behind leaf assembly. Press flat under weight

back curl to the center of each leaf.

Push fully into place until bottom tabs catch at

base square edge.

Glue tabs to underside of base square.

NOTE that it may be helpful to invert platform assembly

Glue tabs to underside of base square.

NOTE that it may be helpful to invert platform assembly

on flat surface to apply fingertip pressure all around

tier 2. Also . . .

outer surface approx. 1/2" above platform, then . . .

. . . position and slide tiers assembly over column . . .

. . . and slide downward into position so that bottom tabs

. . . position and slide tiers assembly over column . . .

. . . and slide downward into position so that bottom tabs

to platform panel underside.

NOTE it will be helpful to place platform base-down

on flat work surface and apply finger pressure in

makes it completely stable standing. However, if you

are concerned about it tipping over, consider hot melt

gluing a few large metal washers as weights onto

the interior walls of the column at this point in assembly.

37. Apply adhesive to the underside of the platform

37. Apply adhesive to the underside of the platform

top accent layer. Then position it over the layered base,

and glue the platform together, taking care that outer

edges align as precisely as possible all around.

Apply pressure along all four edges to firmly attach.

If possible, place weights along the edge margins

to help avoid warping or curling of these edges

during the drying process.

38. If desired, "decorate" the stem tube with lightweightcraft wire. Beginning on backside, hide the top wire end

next to the post side behind the blossom disc.

Wrap the wire in an even, slightly angled spiral with

wire wraps spaced approx. 1/2" apart.

Pause the wrapping approx. 2.5-3" down . . .

. . . to position and attach the first leaf (left oneon the sample project) by wrapping the stem around

post from front toward back. NOTES: A) position

the leaf so that it will fall between the wire wrap lines;

B) leaf face should be oriented toward FRONT of post, as

you may notice by the brad prongs showing on disc, above.

39. Continue the wrapping of wire, pausing to

39. Continue the wrapping of wire, pausing to

attach the second leaf on opposite side 1-1.5" below

that post will remain exposed once bottom end is

inserted into stand. Complete the final wrap toward

one side or back, and cut. Apply a dab of quick-grab

adhesive neatly/invisibly at ends of wire, if desired.

then position (centered) on backside of petals assembly.

inside the petals cup with edge facets aligned

with petals. Hold in place until joined.

NOTE: glitter decoration has been applied to

the grille and to the dome edges of the sample project.

end through column opening and down through

column until it "seats" into . . .

. . . the anchor square hole of collar stack now

concealed inside on base surface. (Post end is seen

here slightly beyond the platform bottom surface.)

For a permanently-assembled project, the post end

could be glued inside the collar at bottom an top.

However, it may be convenient to be able to disassemble

for seasonal storage, then reassembled for later display.

Here is the completed project.Consider building a second flower using the shorter