Facetted heart front and

back domes are edge-joined

to form dimensional “puffy” heart which is mounted

on a dowel-reinforced square post.

Fancy tiered stand with angled checkerboard

accents

anchors the post, and can be invisibly weighted for stability.

Use

this decoration "plain" or with offset multi-patch overlays,

in many settings, as Valentine or other holiday decor,

wedding

centerpiece or serving table accents,

baby shower decoration, and more.

Heart

measures approx. 9.5” wide x 7.625” tall

x 2.5” deep at center;

heart on post

and stand measures approx. 14.75”.

Stand base measures approx. 4.25” x 4.25”.

(1.5”

shorter post shape also included to make

an ensemble pair of hearts which are

two different heights.)

ASSEMBLY: 1. Identify and cut the shapes:

A front heart facetted dome

B back heart facetted dome with finger access windows

C window covers

D interior vertical center support heart

E interior horizontal shelf supports (2)

F post collar support stacks (2 sets of 4-5 each)

G stand base solid shapes stack (4-5) H stand top layer with post anchor hole & slots

I stand base post support collar squares (4-5)

J stand tier 1 K stand tier 2

tier 2 accents: L contrast trapezoid base (4)

M checker overlay (4)

N stand center column

O column post support collar squares (4-5)

P post (wrap for 1/4" dowel)

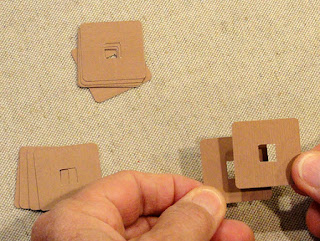

2. Prepare the shapes that need to be glued up into stacks

to be drying as other assembly progresses:

A) layer and glue together the heart post top collar shapes

into 2 sets of 4-5 each, taking special care - here and

throughout - to align ALL cut edges as precisely as possible.

Place the glued-up stack on a flat surface and place

a heavy flat object on top, such as a wooden plank or

the thick book shown here, until fully dried. This will

help minimize curling or warping when using liquid adhesive.

B) layer and glue together square bases; press

under heavy weight until completely dry.

C) layer and glue together each set of post collar shapes,

then press under a flat weight until dried.

NOTE that the collars can also be attached in place

to their corresponding shapes - base and column

(shown in Step 36) - at this time as described in Step 34

to have them dried and ready in regular progression

without need to wait, if desired.

3. Prepare the front dome shape by bending back

on all perforations for facet panels, edge tabs.

the facets which are flanked by narrow tapering end

of wedge tabs, "pinch" the ends of perforation lines

to ensure that the perforation line continues as

crease all the way to the point.

4. Begin to form the shape into a dome by applying glue to the wedge tab at lower left, then overlapping

the straight edge of adjacent facet across wedge tab

to align as precisely as possible at perforation line.

NOTE that it may assist with the completion of these seams to invert the shape on a flat work surface,

adjust so that the seam area is flat, then apply

fingertip pressure across the entire seam, paying

particular attention to the wedge tip area of seam.

5. Next, bend the facet segments to allow the middle vertical seam to be formed by overlapping the straight

edge of inward facet across the wedge tab to

perforation, and complete the seam. Also complete

the mirror image seam on opposite side of front dome.

6. Adjust/allow to bend dome halves to bring top center seam edges to align, overlapping the left side plain edge

to overlap across the tab to perforation line. Adjust

the edges for proper top to bottom alignment,

then glue the seam.

7. Adjust the dome to push the upper seamed area "down" to allow horizontal two-part straight edge

to overlap the left & right tabs near center top seam

(completed in step 6 above), and join seam.

8. Complete the back dome assembly in similar manner. 9. Prepare the heart interior support by bending back

the edge tabs, as well as . . .

. . . bending the center "post" attachment tabs, bending in alternating order, bottom pair forward,

second pair back, etc.

10. Glue the edge tabs in their folded positions, thus creating a thickened edge for increased support.

11. Prepare the two interior "shelf" supports by bending back on all perforation lines, except bending forward

at bottom edge tabs, and at "box" side tabs.

NOTE that as viewed in image below - where bottom tabs

are bending FORWARD - the face side of "shelf" panel

visible is the underside.

12. Position and attach one collar stack at the center U-shaped notch, on the underside of the shelf portion

of the shape. Repeat for second shelf.

13. Form the extension into a "box", bending the bottom flange under to align and attach to upper side of shelf.

14. Apply glue to the underside of the side end flanges, then bend and push toward center

to form box's side wall - push until perpendicular;

attach flange to shelf. Repeat for second side.

15. Position one shelf on front or back face of heart support, with collar/underside downward, and insert

bottom tabs into slots - filling upper half of slot space.

On opposite face of heart support, bend the tabs upward and attach in place.

Apply glue to the narrow bottom of the box, then reposition the "box" to attach to support, forming a

perpendicular support shelf.

16. Repeat for the second support shelf, positioning

it on the opposite side of heart support to where

the first shelf was inserted and attached.

For this second shelf, the tabs are inserted into

the bottom half of the slots, then . . .

. . . tabs are bent downward and glued in place.17. Prepare the post shape by bending back on each

of the long perforation lines for skinny facet panels

and side flange.

18. Form the shape into a tube to overlap the straight

side edge across the opposite flange to perforation line.

Flatten the tube on work surface to apply fingertip

pressure all along the seam until completely attached.

Re-form the shape into its tube form.

Align ends of 1/4" diam. wooden dowel and post tube and

mark on dowel the cut-to-size length. Cut to size

and lightly sand ends.

19. insert the dowel inside and sliding into place so ends are even.

20. Apply glue to the inward surfaces of the center

post opening tabs, and . . .

. . . also into the "well" created by the collar stacks (on each side of heart support) where dowel end

will be inserted. Then . . .

. . . insert the dowel into the space between the post opening tabs, and push firmly into the collar well.

Once post top end is in place, adjust tabs so that

the crease lines of ALL run at the vertical diameter

of post, with the bottom "point" aligned at center

of post face also.

Apply pressure to all post attachment tabs until secure.

21. When post and heart support with shelves unit

is firmly dry, position the assembly into the open back

of the front heart dome and adjust so that ALL edge

flange tabs are extending around the heart shape.

Apply glue to the underside of the first narrow tabs on each side of center top, then bend down around

support edges and glue in place. (Leave the attached

triangle-shaped tabs at center top and center bottom

unconnected til later in process.)

NOTE the heart support is sized to allow a very slight

amount of wiggle room within heart dome edges,

so do a "dry fit" to see where bottom fits best, then

adjust if necessary to "split the difference" of any

gapping that may occur.

22. Bend triangle-shaped "tabs" at center top and bottom out of the way, then place the back dome over

the assembly to center and line up the top two adjacent

angled edges with tab perforations.

Apply adhesive to underside of each top triangle tab then bend down into position to align outer free edges

as closely as possible to back dome facet edges.

Hold each in place until firmly attached.

23. Spread the back dome away slightly and use nozzle of quick-grab adhesive (Fabri-Tack suggested)

to apply adhesive at rim edge of one half of

front assembly. Then . . .

. . . align and "pinch" the edges together and hold together until joined. HINT: move fingers from one facet

edge to another to help all on one side align and join.

24. Bend the bottom triangle tabs over into position as with top triangle tabs and join in place.

25. Identify, position and attach the triangle "covers" overlaid onto the corresponding facets with windows.

STAND 26. Prepare tier 1 platform by bending back on all

perforations for center panel, walls, corner tabs;

also bend forward at bottom edge tabs.

27. Bend the walls back at corners to align straight

edge over inward-bent corner tabs, and join

each corner seam.

28. Prepare the tier 2 platform shape by bending similarly

to tier 1.

29. Prepare the checker panel accents by centering

the checker cutouts on the contrast base trapezoids,

and attaching.

30. Position each checker panel assembly onto

corresponding trapezoid area, centering with narrow

offset margin all around.

31. Bend the platform walls into position to join

each angled side seam.

32. Prepare the column shape by bending back on

perforation lines for side wall panels, forward on

bottom tabs . . .

. . . bending back on "lid" edge perforation, then

forward on the four lines around the lid square.

33. Form the column shape into a tube to align

and join the side seam. NOTE that . . .

. . . it is possible to press the column shape flat

to apply finger tip pressure along the seam edge.

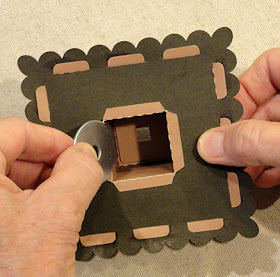

34. Position and attach the two post collar stacks:

one is placed on the backside of the column "lid",

and the other on the top of the base scalloped square.

taking special care that the post square openings are

as precisely aligned as possible.

Press under a flat weight until thoroughly attached.

35. Prepare to bend the column "lid" into place by

applying glue to the wall between column and lid,

and to underside of three other edge flanges.

. . . bend the lid into position to attach connected

wall onto inside of tube, also . . .

. . . tucking edge flanges into tube.

Push lid into position until flange edges are even

with top column edges.

36. Position the column shape (with bottom flanges

bent outward as shown) onto the base shape

with bottom bend edges surrounding the post support

collar stack. Make sure it is centered, then . . .

. . . apply fingertip pressure around bottom to firmly attach in place.

37. Join tiers assembly by inserting tier 2 tabs

through slots on top of tier 1.

At underside of tier 1, bend the "corner-ish" tabs

outward and glue to underside.

38. NOTE that the next couple of images are from

identical assembly steps from a different project

design which has scalloped base edge.

Apply quick-grab glue to lower 1/3 of column sides

(where tier 1 flanges will have a chance to

adhere), then . . .

. . . slide the tier 1 & 2 assembly over top of column . . .

. . . and down into position with column emerging

through tier 2 top window, and . . .

. . . tabs inserted into base slots.

Bend tabs inward and glue in place to underside.

NOTE it will be helpful to place platform base-down

on flat work surface and apply finger pressure in

tab positions to help with attachment.

39. To help prevent stand with heart from tipping over,

consider hot melt-gluing a few large metal washers

as weights onto the interior walls of the column at

this point in assembly.

40. Apply adhesive to the underside of the platform

top accent layer. Then position it over the layered base,

and glue the platform together, taking care that outer

edges align as precisely as possible all around.

Apply pressure along all four edges to firmly attach.

If possible, place weights or "pinch" with folio clips

along ALL edge margins to help minimize warping or

curling of these edges during the drying process.

42. Apply quick-grab glue to bottom of post, then

insert heart/post assembly into the post hole of

column, through tiers assembly, then "fish" around

until post end "seats" into the reinforcement collar

at the bottom. Apply pressure and hold in place

until thoroughly dried.

43. If desired, cut various paper "patch" overlays

for the heart dome facets. To simplify the process of

choosing varied paper patterns that won't inadvertently

line up next to same pattern, and to "balance" the color

values and pattern visual weight, use the shapes as

TRACING TEMPLATES then hand cut with rotary cutter

& ruler or scissors.

44. Below is a diagram for numbering the pieces to help

minimize confusion about which triangle shape fits over which

facet. The cutting shapes provided are for one-half of heart only.

Reverse the shapes to trace & cut the overlays for

the opposite half. If adding patch overlays to back dome

as well, trace & cut 2 sets.

44. It may be helpful to hand number the shapes

to correspond with the diagram above prior to removing

them from the cutting mat after cutting is complete.

45. Position the template shape, trace with .05 or .07

mechanical pencil, trim to traced size, then . . .

. . . position over corresponding heart dome facet

with narrow offset margin all around, then glue

in place.

Here is the patchwork overlay variation.