Caravan capers await with this realistic

dimensional travel trailer box composed of

lid shell (windows, doors, bumper,

hitch)

and base box (wheel support and square axle, and wheels).

Base box color

shows through as "interior" through window openings.

Details include

two-tone side panels, window and door frames,

top vent window, hitch support,

tires and whitewalls, bumper, and more.

Measures approx. 4.125" wide x

6.5" long (plus hitch) x 4.75" tall.

ASSEMBLY:

1. Identify and cut the shapes:

A main trailer base (center and sides)

B trailer base front

C trailer base back

D wheel support with inner bay ends

E wheel bay arch (2)

F axle square tube

G hitch support triangular tube

H wheel tread strips (2)

I inner wheel (2)

J outer wheel (2)

K wheel face with hub circles (2 ea.)

L reflectors and "rims" (2 ea.)

(NOTE: other shapes here were redesigned

and appear in image above as A-D)

M camper shell (upper) with front accents

and top window layers, frame

N camper shell back with back accents

O shell top bands (2)

P left side camper shell panel with accents

Q right side camper shell panel with accents

R hitch support "box"

S hitch top and bottom

T hitch support (this is the same as G)

U door with window, handle liner, frame

2. Prepare the main trailer base, front and back base panels by folding back on the divided bottom panel perforations, end angles, side and end tabs.

3. Join the front and back panels to the corresponding ends of the main trailer base panel. To identify which end to connect the front (F) or the back (*) panels to, look for the symbols in the main panel end tab and the bottom tabs of front and back.

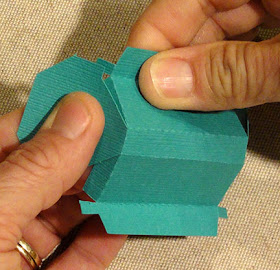

Pointing finger in this image shows the "F" for "front".

Here, the front panel end is being positioned and attached.

4. Fold the main panel angle sections to line up with the angled straight edge and join the short straight edge at the perforation line of the small triangle tab.

Repeat for both sides (eventually).

5. Continue to adjust to bring the long front edge in line with the tab perforation line, and join.

Follow a similar process to bend, align and join the angle section and edges, and long section edges and tabs for both sides of front and back panels.

6. Fold the rim tabs to the inside and glue in place.

7. Prepare the wheel support "box" on the perforations as shown: center two long and ends, and tiny tabs back (mountain folds), long edges folded forward (valley folds).

NOTE: there are widely-spaced perf lines approx. 1/8" beyond valley fold lines that are guidelines and SHOULD NOT be folded.

8. Bend the front and back panels into position to line up the end angle straight edge with the corresponding tab perf line, and glue in place. Complete all 4 similar seams on the box.

Also position and attach the tiny tabs with the very short straight edge at the top of each angle edge.

The prepared assembly will roughly resemble a trough, with the card stock back side on the inside of the trough.

9. Prepare the wheel bay arch shape by bending on each of the series of perforation lines to form the arch, end tabs back.

Also fold the arch edge straight tabs (top of this image) and the wedge tabs back as shown.

10. Prepare to attach the bay arch shape to the five-sided edge of the wheel support assembly by identifying the middle wedge tab, lining it up behind the wheel support top edge and attaching.

11. Bend the arch sections to line up with the corresponding straight edges and attach tabs behind. Attach all five wedge tabs behind straight edges, for both ends.

The completed assembly should appear as shown.

12. Insert the assembly into the main base assembly opening so that the trough portion extends beyond the bottom plane of the base, and wheel bay arch edges follow the arch cut out on the base sides.

Push into place until the front and back horizontal tabs catch behind the base cutout edges.

13. Adjust edges and tabs of insert and base, centering from side to side, etc., then glue edges to tabs.

NOTE ONE: that the dashed guidelines of upper "tab" support extensions should line up with the opening straight edges.

NOTE TWO: straight tabs of bay arch should be glued to the inside of the base sides, with perforation folds lining up with the arch opening edges. (See second image with step 21 for a clearer view of these edges.)

14. Prepare the axle strip by folding back the long perforations.

15. Form the axle strip into a "square" tube, with long end edge overlapping the opposite long tab. Glue the long edge in place to the tab beneath.

NOTE: it will be helpful to insert a narrow rod tool like a knitting needle or bamboo skewer inside the tube to provide a pres-against surface to secure this seam.

16. Prepare the wheel "tread" strips by bending on the series of perforations, folding side tabs and end tab back.

17. Form the tread into a ring to bring the end straight edge to overlap the end tab, adjust side to side for alignment, and glue edge to tab.

Complete for both tread strips.

18. Position the ring inner wheel 12-sided shape over one end set of tabs.

Line up and attach two tabs across the wheel shape, and glue the edges to the tabs, then "squash" the ring to line up all of the remaining perforation lines at the wheel edges and glue in place.

19. Fold tabs inward, align edges of axle outer wheel at tab perf lines as for inner wheel in step 18, adjust and glue edges and tabs.

Repeat for the second wheel.

20. Insert one end through the axle hole and push inward until . . .

. . . only the end tabs remain beyond wheel.

Fold tabs back and glue in place.

21. When the first wheel is securely attached to axle, insert the opposite end through the axle holes in the wheel support box . . .

. . . then insert through the second wheel axle hole.

22. Fold the end tabs back and glue in place as before.

23. Assemble wheels and hubs by layering and gluing together.

24. Insert and glue the brad in place without bending the prongs, but simply . . .

. . . insert the prongs into the axle tube. Glue the backside of the wheel circle in place to the dimensional wheel.

Repeat for second wheel.

25. Assemble the top window and door layers in order and general positioning as shown here.

NOTE that dark contrast shapes line the window slider and door front to make the handles visible.

26. Prepare the shell main shapes by folding back on horizontal perforations, edge tabs

back.

27. Position and attach the lower half accent shapes, window frames and door assembly.

Take care that the hitch box slots of the lower panel and front hull shapes line up exactly. Pushing a blade tool into slot may help line up the layers.

28. Join the front and back center panels by overlapping the straight edge (front) over the tab to perforation line.

NOTE that the tiny circle symbols in the tabs help identify the edges that should join.

29. Position and attach the top window onto the center panel assembly as marked with positioning cuts.

30. Join the right side hull to the corresponding tabs of the center panel.

Repeat for the left side hull.

31. Fold the edge tabs to the inside and glue in place.

32. Add the additional accent shapes, including the wheel bay arches, side edge echo accents, top strips (bend strips at perforations and line up with bend perforation positions).

33. Prepare the hitch support box by foling back on all the perforations, except leave tabs straight.

34. Bend the sides inward to line up the side straight edges of the bottom (shown) and top with the side tab perforations, and glue in place.

Complete both sides to create a trough shaped "box."

35. Layer the hitch upper and lower shapes and glue together.

NOTE: the upper hitch has been modified in the final cut file design to eliminate the edge tabs that are shown in this image.

36. Position and glue the hitch assembly over the upper surface (triangle cutout is in the underside surface), with straight bottom edge at box edge/tab perf lines, and with sides lined up.

(Hitch upper shape has been modified in final cut file to eliminate the end tabs that are shown in this image.)

37. Line up and insert the 8 tabs into the slots on the front panel . . .

. . . push fully inside, then fold tabs back and glue in place on the inside of the hull.

38. Prepare the bumper strip by bending ends back.

Line up each end punch hole over the corresponding holes on hull sides, and glue the area around the holes in place.

Insert mini brads through holes and bend to secure the prongs on the inside of hull.

Layer tail reflectors and attach.

17. Form the tread into a ring to bring the end straight edge to overlap the end tab, adjust side to side for alignment, and glue edge to tab.

Complete for both tread strips.

18. Position the ring inner wheel 12-sided shape over one end set of tabs.

Line up and attach two tabs across the wheel shape, and glue the edges to the tabs, then "squash" the ring to line up all of the remaining perforation lines at the wheel edges and glue in place.

19. Fold tabs inward, align edges of axle outer wheel at tab perf lines as for inner wheel in step 18, adjust and glue edges and tabs.

Repeat for the second wheel.

20. Insert one end through the axle hole and push inward until . . .

. . . only the end tabs remain beyond wheel.

Fold tabs back and glue in place.

21. When the first wheel is securely attached to axle, insert the opposite end through the axle holes in the wheel support box . . .

. . . then insert through the second wheel axle hole.

22. Fold the end tabs back and glue in place as before.

23. Assemble wheels and hubs by layering and gluing together.

24. Insert and glue the brad in place without bending the prongs, but simply . . .

. . . insert the prongs into the axle tube. Glue the backside of the wheel circle in place to the dimensional wheel.

Repeat for second wheel.

25. Assemble the top window and door layers in order and general positioning as shown here.

NOTE that dark contrast shapes line the window slider and door front to make the handles visible.

26. Prepare the shell main shapes by folding back on horizontal perforations, edge tabs

back.

27. Position and attach the lower half accent shapes, window frames and door assembly.

Take care that the hitch box slots of the lower panel and front hull shapes line up exactly. Pushing a blade tool into slot may help line up the layers.

28. Join the front and back center panels by overlapping the straight edge (front) over the tab to perforation line.

NOTE that the tiny circle symbols in the tabs help identify the edges that should join.

29. Position and attach the top window onto the center panel assembly as marked with positioning cuts.

30. Join the right side hull to the corresponding tabs of the center panel.

Repeat for the left side hull.

31. Fold the edge tabs to the inside and glue in place.

32. Add the additional accent shapes, including the wheel bay arches, side edge echo accents, top strips (bend strips at perforations and line up with bend perforation positions).

33. Prepare the hitch support box by foling back on all the perforations, except leave tabs straight.

34. Bend the sides inward to line up the side straight edges of the bottom (shown) and top with the side tab perforations, and glue in place.

Complete both sides to create a trough shaped "box."

35. Layer the hitch upper and lower shapes and glue together.

NOTE: the upper hitch has been modified in the final cut file design to eliminate the edge tabs that are shown in this image.

36. Position and glue the hitch assembly over the upper surface (triangle cutout is in the underside surface), with straight bottom edge at box edge/tab perf lines, and with sides lined up.

(Hitch upper shape has been modified in final cut file to eliminate the end tabs that are shown in this image.)

37. Line up and insert the 8 tabs into the slots on the front panel . . .

. . . push fully inside, then fold tabs back and glue in place on the inside of the hull.

38. Prepare the bumper strip by bending ends back.

Line up each end punch hole over the corresponding holes on hull sides, and glue the area around the holes in place.

Insert mini brads through holes and bend to secure the prongs on the inside of hull.

Layer tail reflectors and attach.

39. Prepare the hitch support triangular support by bending on perforations, forming a tube with straight edge overlapping the tab perforation line, and gluing in place.

Insert through the triangle opening on the underside of the hitch support box. Push inward as far as necessary to assist camper trailer to sit in horizontal position.

Glue in place as you are able.

40. To close the box, insert the base into the interior of the hull, and push hull down until bottom of hull lines up with the bottom corner of the base.

Here is the finished camper box.

This comment has been removed by the author.

ReplyDeleteI love this little camper! I was so disappointed to read in the design store that it will only work with 12" X 12" card stock, since I have a Portrait!

ReplyDeleteHi. I love this file. What weight of cardstock do you recommend using for this box? TIA

ReplyDelete65 lb or higher, up to 100 lb. weight. Usually is described as textured card stock. I use brands carried by JoAnn Fabrics, Michaels, and Hobby Lobby.

Delete