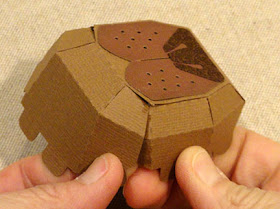

(partially articulated; legs are glued in sitting position)

is constructed of dimensional units with sturdy card stock.

Assembly is completed with narrow ribbon or twine threaded

through two-hole 5/8" -

3/4" buttons at arm and leg joints.

Interior stabilizer tubes

provide strength and channel for threading.

Measures

approximately 13.75" (sitting as shown).

(NOTE this design requires TWO file downloads

to obtain all the shapes that compose the bear.)

(NOTE this design requires TWO file downloads

to obtain all the shapes that compose the bear.)

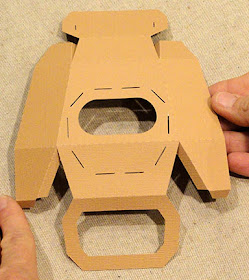

ASSEMBLY: 1. Identify and cut the shapes:

Body Unit: A body side/front B tummy accent

C body side/back D shoulder post (tube)

E hips post F tail

G back (finger hole) cover H seat cover

Leg & Foot Unit (2 ea.): P upper leg

Q leg/hip tube (marked X) R leg under covers

S lower leg T ankle tube (marked X)

U foot V (upper leg) knee tube (marked X)

W paw accents

as well as the same front side seams on

the other half of the head front unit.

(centered, with offset margin around)

on muzzle face panel section of muzzle shape,

and glue in place.

11. Assemble top of the muzzle unit by

bending segments to align angle seam

straight edge and adjacent

tab perforation line for all upper seams.

Also, align muzzle face panel edge at

corresponding segment tab and glue in place.

upper tab of lower side panel under the

muzzle face edge while overlapping the

lower side seam straight edge to tab perf

to join, for both left and right sides.

and glue in place.

"star" tabs pushed outward.

Complete all seam segments on both

body halves.

folding and creasing

ONLY

along long perforation lines.

(Leave end tab unbent for ease in inserting

through tube openings.)

Form into a tube to bring the straight long edge

to overlap the opposite flange perf line, and glue

in place.

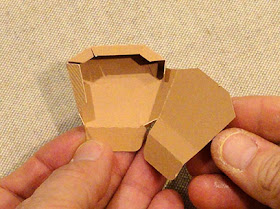

NOTE that the tube can be flattened to

assist in the gluing of the flange tab,

as shown here.

(All post tubes are prepared in similar manner.)

opposite side opening. . .

bending back at the horizontal perforations.

(Center slot line remains unbent,

intended to suggest a stitched seam.)

Bend remaining boxing tabs inward.

This is how the tail unit should appear at the

end of Step 34.

and glue in place.

To further secure attachment, use a quick-grab

adhesive such as Fabri-Tack liquid or hot glue gun

applied discreetly between head and body.

. . . side panels are completely attached.

42. Bend arm front panel tabs inward . . .

(shortest tube shape), insert through openings,

bend back and attach end tabs.

into the lower tube opening of each

lower leg.

prepared foot unit, front of leg oriented

to the toe end of the foot.

Apply glue between the foot and leg

to attach.

59. Insert the upper leg between the rounded

flanges of the lower leg top to line up the

punch holes and the tube at knee position . . .

. . . and also lining up the knee front cross edge

closely to the upper front straight edge

of lower leg, as shown.

Apply glue between the rounded flanges of

the lower leg and the upper leg to join.

61. Thread each end through separate holes

of joint button, tie knot and bow. Trim ends.

(Apply dab of clear glue to secure bow.)

Repeat for the opposite side.

backside of figure.

Body Unit: A body side/front B tummy accent

C body side/back D shoulder post (tube)

E hips post F tail

G back (finger hole) cover H seat cover

Head Unit: I head front with top & bottom panels

J bottom cover K head back L back cover

M ear left & right with inner ear accents

N muzzle O muzzle accents, nose, eyes (2)

Q leg/hip tube (marked X) R leg under covers

S lower leg T ankle tube (marked X)

U foot V (upper leg) knee tube (marked X)

W paw accents

Arm Unit: (left & right)

X arm Y elbow crook boxing strip

Z arm shoulder tube

AA upper arm cover

BB lower arm cover & paw accent

BB lower arm cover & paw accent

HEAD UNIT

2. Prepare the head front shape by bending

back on all perforation lines for panels and

tabs as shown.

3. Prepare head back by bending back on all

perforation lines for panels and tabs as shown.

4. Assemble the head front by bringing

straight edges to overlap adjacent tab/flange

to perforation line and glue in place. Do this for

the 4 section seams, like the lower front side

seam shown here . . .

. . . and the upper front side seam shown here,as well as the same front side seams on

the other half of the head front unit.

This is the front unit after the Step 4 assembly.

5. Assemble the head back unit by bending

to bring straight edge to overlap the adjacent

tab/flange for the long seam and three shorter

seams on each side of the head back.

Do this for the long side back seam shown here . . .

. . . and for the lower seams like the seam

shown here . . .

. . . and the upper seam shown here.

Here is the head back unit after

Step 5 is complete.

6. Join the head front and head back at

the side seams, one at a time, by

overlapping the straight edge of front head

at the corresponding tab/flange to

align with perforation line, and gluing

in place. NOTE that it will be helpful

to reach fingers into the openings

to apply pressure along the seam from

front and back, here and throughout

construction.

7. Bend the assembly to align the

remaining edges to overlap tabs to

complete lower . . .

. . . and upper portions

of side seams on both halves of head unit.

MUZZLE

8. Prepare the muzzle shape by bending back

on all perforation lines for panels and tabs,

EXCEPT leave tabs at extreme top and bottom

unbent (to assist with insertion into head slots).

9. Prepare the muzzle accent shapes by attaching

nose at top of muzzle front, and attaching

muzzle contrast behind so that color shows

through whisker hole and center line.

10. Position muzzle accent (centered, with offset margin around)

on muzzle face panel section of muzzle shape,

and glue in place.

11. Assemble top of the muzzle unit by

bending segments to align angle seam

straight edge and adjacent

tab perforation line for all upper seams.

Also, align muzzle face panel edge at

corresponding segment tab and glue in place.

12. Continue muzzle assembly in similar manner

by bending, joining seams along bottom

of unit, as shown here . . .

. . . then complete final seams by tuckingupper tab of lower side panel under the

muzzle face edge while overlapping the

lower side seam straight edge to tab perf

to join, for both left and right sides.

13. Position the completed muzzle at the head front

and insert edge tabs into corresponding slots

on head front, working them all gradually in

until muzzle fits flush against head front

and angled lower front surfaces.

On the inside of the head, bend the tabs outwardand glue in place.

EARS

14. Prepare the ear shape by bending rim flanges

at outer (rounded) edges back, as well as

perforation lines that are "parallel" to flange lines.

The "arrow" symbol cut indicates the TOP tab.

NOTE it may be helpful to leave end and center

tabs along the lower edge un-bent until later.

Also bend back the narrow wedge tabs between

segments, as indicated here . . .

. . . taking care to finger crease these wedge tabs

all the way to the "corner" angle.

15. Assemble the ear by bending to bring

the short seam straight edge to overlap

the adjacent wedge tab perf line, and glue in place.

Complete the six seams, for both left & right ears.

16. Apply glue to underside of rim flanges,

then bend to the inside of the ear and glue

in place.

17. Position the appropriate inner ear accent

shape inside the ear unit, with center tab

edges lined up, curved edge offset within

the ear main panel, and glue in place,

except . . .

. . . leave center tabs unattached so they can

be bent in different directions when ear

is being attached to head.

Complete for both ears.

(NOTE that the inner ears for this model

have been distressed and colored using

edge darkening accent ink, with blended

opaque pink with reg. red accent ink.)

18. Align the appropriate left or right ear at

the upper side edge of head, and insert the

tabs into corresponding slots in the head.

It may be helpful to insert top tab last.

On the inside of the head, bend the tabs

forward (one of center tabs bends back)

and glue in place to the inner surface.

EYES

19. Layer eye and underlay accent "show thru"

shapes . . .

. . . then position on the front of the head

above muzzle and glue in place.

20. Bend the head bottom "frame" panel into

position, align and attach long edge and

corresponding tab/flange, then adjust and

attach remaining edges and tabs all around.

21. Position and attach bottom "cover", with"star" tabs pushed outward.

22. Bend the top panel into position and

attach to corresponding tabs

in similar manner.

BODY

23. Prepare the body units by bending back

on all panel and tab perforation lines.

Here is the body right side/front unit . . .

and here is the body left side/back unit.

24. Assemble the body in similar manner

to the head, bending to align straight seam

edge to adjacent tab perforation line,

for each segment of the seam, on all sides

that require seaming.

Here, the first upper segment of seam

is joined . . .

. . . then the top segment.Complete all seam segments on both

body halves.

25. Join the body halve along one side seam,

by aligning the corresponding seam edge

and tab, overlapping and completing seam.

Then move upward and downward to complete

the other seam segments.

26. Form the body into a tube to bring

opposite side edge(s) and tab perforation line(s)

together, overlap and complete segment seams.

27. Bend the body bottom panel into position,

adjust to align straight edges and tab perf lines,

then glue to complete seams.

28. Prepare the hip post (tube) by carefullyfolding and creasing

ONLY

along long perforation lines.

(Leave end tab unbent for ease in inserting

through tube openings.)

Form into a tube to bring the straight long edge

to overlap the opposite flange perf line, and glue

in place.

NOTE that the tube can be flattened to

assist in the gluing of the flange tab,

as shown here.

(All post tubes are prepared in similar manner.)

29. Insert tube through hip tube opening on

one side of body unit . . .

. . . slide through interior to insert throughopposite side opening. . .

Bend end tabs outward and glue in place.

Repeat for opposite tube end.

30. Bend top panel into position, adjust for

edge alignment, and glue in place.

31. Repeat the tube prep, insertion and end tab

gluing process for the shoulder tube,

except should tube has angled ends to

line up more appropriately with body shaping.

Shorter side of tube should be inserted as

TOP position, and end tab may need to

be bent back for gluing

independent of it's perforation.

32. Prepare the tummy accent shape bybending back at the horizontal perforations.

(Center slot line remains unbent,

intended to suggest a stitched seam.)

Position tummy, centered side to side,

onto body front, with bends aligned.

TAIL

33. Prepare the tail shape by bending back on

all panel and tab perforation lines

except bottom edge rounded tabs

should be bent upward.

34. Assemble the tail by bending the "boxing"

strip perpendicular to tail bottom panel

to align and attach straight edges with

boxing tab perf lines, one by one.

Also bend side panels back to align and join

short seams, first on one side, then . . .

. . . on the opposite side.Bend remaining boxing tabs inward.

This is how the tail unit should appear at the

end of Step 34.

35. Bend the tail front panel into position

to align edges with boxing perf lines,

adjust, and glue all tabs and edges . . .

. . . including the end angled edges.

End tabs should remain unattached,

to allow them to be bent in opposite directions

to be attached inside body.

36. Insert end tabs of completed tail unit

into body back slot, bend tabs up or down

separately, and glue in place.

BODY & HEAD ASSEMBLY

37. Position the head over the body

(orient so head and body FRONTS

correspond) with star tabs inserted into

the hex opening at body top panel.

Then . . .

. . . bend triangle tabs back on the inside of bodyand glue in place.

To further secure attachment, use a quick-grab

adhesive such as Fabri-Tack liquid or hot glue gun

applied discreetly between head and body.

38. Apply glue at edges, then position and

attach finger hole covers: head back,

body back and body seat.

ARMS

(Complete one each left & right.)

39. Prepare the arm units by bending back on

all perforation lines for panels and tabs.

Also prepare the arm crook "add on" strip

by bending tab flanges back, bending

forward at vertical perf line.

40. Identify the edge at arm crook where

add-on strip will attach . . .

then position straight edge of add-on along

tab perf line . . .

. . . and attach.

41. Assemble the arm by bending sides up

to line up straight edges at adjacent perf lines,

and attach.

Join seam all around arm until . . .. . . side panels are completely attached.

42. Bend arm front panel tabs inward . . .

. . . then bend top into position with tabs tucked

inside the side edges, and glue in place.

NOTE: insert fingers through backside

openings to apply pressure to edges.

43. Prepare arm shoulder tube (shortest tube shape), insert through openings,

bend back and attach end tabs.

44. Prepare the lower arm covers by attaching

paw accent shape at end, edges slightly offset.

NOTE that the arm cover AND the paw accent

have a slight corner; use these to identify

the shapes that go together.

45. Position both arm covers over the

openings, as shown.

(NOTE that the "corner" position of the

paw accent and cover are in the

"thumbs-up" position on the arm.)

LEGS

46. Prepare the leg unit by bending back on all

perf line for panels and tab flanges.

47. Bend the "boxing" strip long end into position

to line up straight edges of one side with

corresponding tab perforation lines, then glue

each tab in place along one side.

Repeat the alignment process for tabs

on short "boxing" strip segments, tucking

end tab under opposite straight end edge

to glue in place.

48. Bend the second side into position,

adjust to line up seam edge segment with

corresponding tab, and glue all in place.

49. Prepare hip end and knee end tubes,

then insert into and through tube openings

to complete attachment of both for each upper leg.

50. Position and attach the finger opening cover.

51. Prepare the lower leg shapes by bending

back on all vertical perforation lines.

52. Bend the lower leg into a tube to overlap

the straight long edge over the opposite

tab to perf line and glue in place.

53. Prepare, insert and attach a tubeinto the lower tube opening of each

lower leg.

FOOT

54. Prepare each foot shape by bending

back on all panel and tab perforation lines.

55. Layer the paw outline on top of the

paw base for two feet.

Position one on the center panel of each foot

shape, center, and glue in place.

Take care that the toes are oriented

toward the two-section front end of the foot shape.

56. Bend the front and back sections into position

to line up the side straight edges at their

corresponding tab perf lines, and glue in place

to form foot shape.

57. Identify the front of the lower leg,

which has a higher cross edge

a indicated . . .

. . . then insert the lower leg into theprepared foot unit, front of leg oriented

to the toe end of the foot.

Apply glue between the foot and leg

to attach.

59. Insert the upper leg between the rounded

flanges of the lower leg top to line up the

punch holes and the tube at knee position . . .

. . . and also lining up the knee front cross edge

closely to the upper front straight edge

of lower leg, as shown.

Apply glue between the rounded flanges of

the lower leg and the upper leg to join.

BUTTON JOINT ASSEMBLY

60. Position each leg at sides of lower body

(toes forward to match tummy position -

image shows from backside) to roughly

line up the hip tubes.

Thread two 15-18" lengths of narrow ribbon

or twine onto a long doll needle and pass

through all tubes, make exposed ends even.

of joint button, tie knot and bow. Trim ends.

(Apply dab of clear glue to secure bow.)

Repeat for the opposite side.

62. Repeat this process with arms at

shoulder joint tubes of body.

63. Thread pairs of ribbon (or twine) lengths

through knee, ankle joints, then each

end through button on each side of joint

in similar fashion to hip joint,

tie knot and bow, trim, glue.

Here is the completed bear showingbackside of figure.

No comments:

Post a Comment