This large project features a realistic

sleigh-style

headboard cradle and stand.

Cradle has end posts that fit into

stand leg

openings to allow it to rock.

Stand has cross-braced tray that

connects

end stanchions.

Measures approx. 10.25" tall x 4.375" deep x 10"

long.

Duplicate layers are glued together

to add thickness to and strengthen components.

An elaborate

"gift box", this model can be used as

baby shower or nursery decor, miniature

dolly bed, and more.

Companion "crib mattress" box can be

placed in the cradle bed for extra realism.

(Find the mattress box as a FREE download design

at SnapDragonSnippets.com by following this LINK.)

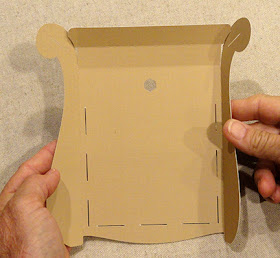

ASSEMBLY: 1. Identify and cut the shapes:

A headboard and foot board dimensional shapes (2)

B headboard and foot board cross brace (2)

C foot/headboard upper contour reinforcement panel (2)

D rocker post shape (2)

E foot/headboard outer panel reinforcement (2)

F foot/headboard accent overlay (2)

G side rail fold-over panels (2) H top rail contr. accent (2)

I cradle bed (base) with tabs J base reinforcement (1-2)

K sleigh bed end piece (10+2 contr for each left & right)

L stand end leg base (with slots; 2) M stand leg build up (16)

N stand tray main shape O tray bottom build up (2)

P tray side panels build up (4) Q tray side accent overlay (2)

R overlay inner oval shapes (2) and punch cut "nails" (8)

S tray middle divider (2)

NOT SHOWN: post tabs cover shape (2; see Step 15)

T stand legs outer accent overlay (2)

2. Prepare the cradle base shape (letter I) by

bending the side flanges forward and

bending the end tabs back.

3. Layer the cradle base reinforcement (build up)rectangles and glue together.

NOTE: beginning with this "build up" reinforcement

step and throughout this project,

use a flat weight such as the re-purposed weight machine

weight bar covered with muslin that is shown

in Step 27, place the glued-up shapes under

a weight until completely dry to help prevent

warping and curling.

4. Position and attach the cradle bed build up unit

on the bottom of the cradle base,

centered inside the perforation lines or cut edges.

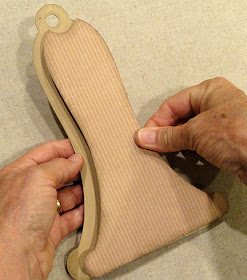

5. Prepare the side rail shapes by folding

the rail shape at the cross perforation at middle

so that the face side is outside. Unfold.

Apply glue to the underside surface of one half,then re-fold to glue the surfaces together to

create double-layer rails.

End tabs should remain unattached.

6. Prepare the headboard and foot board shapes

by bending the side "rail" extensions back

(the shape is shown here from backside)

and also bend the upper contour panels

back along perforation lines,

with side tabs bent back also.

7. Layer one accent panel over a reinforcement

(matches headboard or foot board) panel,

with even offset margins at bottom and sides

(top offset has shaped margin), with post hole

openings of each aligned, and glue in place.

8. Position and attach the end panel units

on the backside of each foot or headboard,

within perforation lines, and with post hole

openings aligned.

9. Position a side rail section bottom edge

along the side bottom flange edge of the cradle

base unit, with edges and ends aligned,

and glue in place.

Repeat for opposite side of cradle base and

second side rail section.

NOTE: cradle base flange edge and rail section

bottom edge must align "perfectly" to allow

this unit to fit into headboard and foot board.

10. Carefully work cradle base end tabs into

corresponding slots on headboard near bottom,

then work side rail end tabs into their slots,

and snug headboard into position so that

tabs are fully through to the outside.

Bend side tabs inward, bottom tabs down,

and glue in place.

Repeat for the foot board.

11. Prepare the post (cover) shape by bending back

on all panel, tab and cap perforation lines as shown.

12. Shape the post body into a tube, busing

a 5/16" diam. wooden dowel as a wrap-around form

to bring the straight side edge to overlap the opposite

tab to perforation line, and glue in place.

Also bend the top cap end tabs inward

and fold the attached hex cap into position

and glue in place.

NOTE: it may be helpful to leave the dowel

in place inside the post, with top flat end

even with tab and cap perf marks

to provide a press-against surface for gluing.

13. With post shape snug on dowel which is

pushed fully in, bend the bottom tabs away

and mark the post length on the dowel.

Cut dowel at mark (remove the mark while sawing);

repeat again for second post.

Insert each dowel nib into the prepared post shape

and glue inside.

Make sure bottom of dowel does not extend

beyond the post length when bottom tabs

are bent out of the way.

14. Insert each post unit through the headboardor foot board, working from

the inward face of the headboard

so that it covers the post tabs and opening,

and so that it is centered side to side,

then glue in place.

Repeat for the opposite cradle end.

into "curled" position to insert each side tab

into corresponding slot, then bend tab down

and glue in place. Repeat for second side,

then for opposite end.

17. Prepare the headboard contour reinforcement

panel shapes (C in shapes layout) by bending

back slightly at perforation line.

18. Position one reinforcement panel centered at

the contour of headboard upper end,

so that the perforation lines align,

and glue in place.

Position and attach the second reinforcement

in prescribed position on opposite end board.

19. Prepare the headboard cross brace by

bending at perforations as shown,

with top edge rectangle bent back and

lower edge shaped panel bent forward,

end tabs bent forward.

20. Form the lower panels into a right angledtray shape, with end tabs overlapped

(curved end panel at inward-most position)

and glue in place to maintain the right angle corner.

Repeat for opposite end

Also fold the top flange back into position

and glue all across to form reinforced ledge.

21. Position the cross brace at bottom

of headboard inside the side "posts"

and with shaped edges lined up,

and glue in place.

Also glue end panels to "post" surfaces

where they touch.

Repeat for opposite foot board.

22. Prepare the contrast top rails for side rail

panels by folding back along center perf line.

23. Position along top of side rail panels

so that they overlap around the top edge

and fold snugly flat, and glue in place.

Repeat for second contrast rail.

24. Layer 5 end rail shapes plus top contrast shape

into a stack, one by one, and glue all together,

taking care to align all cut edges as precisely

as possible. Use weight to flatten during

gluing process.

Prepare 2 RIGHT and 2 LEFT stacks.

25. Position the matching endpiece stack over

the attached endpiece portion of headboard

or foot board, align shaped edges that should

correspond, and glue in place.

26. Identify the inside layer shape for the stand legs

by locating the slots that will accept

the tray end tabs.

27. Layer exterior stand leg shapes into

two stacks of 8 each, taking care to match up

all cut edges and hole opening edges as

precisely as possible.

NOTE: use flat weight as previously described

to flatten the glued-up shape until glue is completely

dried, to avoid warping or curling of the paper shapes.

Layering of stack may be best executed if layered

in a series of 4 or so, flattening for a period,

then continuing to layer on the remaining shapes

and returning flat weight onto stack until dry.

28. Also layer on and attach the accent leg shape

onto the "front" of each leg stack,

with offset margins all around.

29. Prepare the stand tray shape by bending

side panels forward with end tabs bent back.

30. Layer the tray bottom shape, and pairs of

side panel reinforcement shapes with all

cut edges aligned, and glue each set together.

Use flat weight while gluing.

31. Position the side accent shape overlayonto each reinforcement build up shape, centered,

and glue in place. Then . . .

. . . position and attach the center ovals

and the "nail head" punch dots.

32. Prepare the tray center divider shapes by

bending side and bottom tabs forward.

Layer the two shapes back to back and glue

panels together, taking care that tabs remain

unattached.

33. Unbend tabs so they are back to back,

then insert each set into bottom or side slots

of tray shape . . .

. . . then on the outside of tray, separate and

bend tab pairs to lay in opposite directions,

and glue in place to tray.

34. Position the bottom reinforcement ontothe underside, centered, and glue in place.

35. Fit tray end tabs into the leg base slots, then . . .

. . . on the leg backside, bend side tabs inward,

and bottom tab upward, and glue each in place.

36. Position the leg build up stack over the leg

and tray assembly with all cut edges lined up

and glue in place.

Use weights to press in place while glue dries.

Repeat for both legs.

MATTRESS BOX ASSEMBLYIdentify and cut the shapes:

A main mattress box shape

B tufting grid cutout

C button circle cutouts (17)

D interior support "struts" (2)

37. Prepare the main box shape by bending back

on all panel, side, top & bottom, and tab perforation

lines.

38. Center and attach the "tufting" grid cut out shape

onto the top/front panel of the mattress box.

Position and glue each of the button

punch circles at the intersections.

bring the side panel to overlap opposite

flange to perforation line . . .

. . . and glue flange in place

to backside of wall.

NOTE that this symmetrical shape will allow

flattening so that finger pressure can be

applied along the entire length of the side seam.

40. At bottom end, bend side tabs and long

tab in, then bend end wall into position

and glue in place to close that end of box.

41. Prepare the support struts by bending each

at center perf line, then . . .

. . . invert one strut so that the slotscan fit together, and the two strips pushed together

so top and bottom edges of both are at same level.

42. Insert the strut support unit into the open

end of the mattress box and slide inside

completely.

43. Place the mattress box into the cradle

and allow it to slide down fully into place.

the cradle between stand legs, then placing

the rocker opening over the post, one then

the other. Adjust to center it.

Here is the completed cradle rocker

on its stand.

This comment has been removed by a blog administrator.

ReplyDeleteOh my goodness this is absolutely awesome, I love it.

ReplyDeleteWow Jodi - amazing! <3

ReplyDeleteAs always Jodi, you do amazing work. I can't wait to make this project. Tell me, I have been unable to access the mattress. When will it be available?

ReplyDeleteProbably later today, through SnapDragonSnippets.com of course. If you are desperate for it before then, email me directly at hearthsewnpatterns(at)yahoo(dot)com and I can send it along to you as an svg file (free).

DeleteThank you responding so quickly. I can wait another day. Right now, I am finishing up your 3D Aloha Pineapple for one of my grand-daughters. Just want to say, I truly love the work that you do.

ReplyDeleteThank you,

Monica

Oh my goodness! This is such an amazing piece of art! I really don't know how you continue to create such amazing things, but you always do!

ReplyDeleteIs the mattress box still available?The link isn't working.

ReplyDeleteLove this project! Is the mattress box still available? The link no longer works

ReplyDeleteShould be. I'm on the road, but will try to remember to plug in my separate hard drive when I'm back at homebase soon.

ReplyDeleteHi. I actually found it as attachment in an old email to another patron. It is an svg file. If you still need it, please contact me at hearthsewnpatterns@yahoo.com and I will attempt to attach and email it back to you that way.

Delete