Build a wedge-shaped vessel, attach

the dimensional

heart "wing" (to front only), add two-part beak,

Tail, wattle and comb

that are layered for thickness,

glue some metal washers in the "hold"

back half

for ballast to keep hen from overbalancing.

Farm yard character will

be ready to add

to your country decor.

(Panel openings in back hull allow

finger access

to assist assembly.)

Measures approx. 9.75" long x 8"

tall x 2.75" wide.

ASSEMBLY 1. Identify and cut the shapes:

A front body panel (includes wing box slots)

B front accent

C back body panel (includes trap doors) D back accent

E & F wedge boxing panels

G top boxing shape with front & back top segments

H top body accent

I internal support (2)

J beak upper and lower K eye contrast underlays

L trap door connector circle tabs

M wattle front and back tabbed shapes, build up (7-8)*

N comb front and back tabbed shapes, build up (7-8)*

O tail front and back tabbed shapes, build up (7-8)*

* quantity is determined by thickness of paper -

see Step 2 for thickness test info

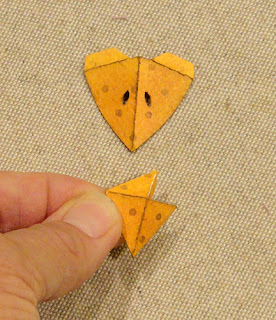

P heart box main structure

Q add on top boxing strip

R heart accent overlay

2. To determine how many wattle, comb and tail

build up shapes are required, layer the 7 or 8 build upshapes of comb, then compare to the paired slots

on the top boxing shape slots.

When the tabs of front and back shapes will

fit properly into the slots, the correct thickness

and quantity of build up shapes is determined.

3. Prepare build up stack of comb by positioning

and attaching each of the determined quantity

one on top of the next, taking care to align all

cut edges as precisely as possible.

It is recommended to use a flat heavy weight

such as this muslin-covered free weight bar or

equivalent (many household flat objects may

serve the same function) placed on top of

the build up shapes. This will help the stack

remain flat and smooth, avoiding warping or

curling while liquid adhesive dried completely

(can require a few hours).

4. Bend the tabs of front and back comb outward,then . . .

. . . position on corresponding top or bottom of

stack and glue in place.

Use weight to press the stack with tabbed shapes

attached until dry.

(NOTE also use weight for all stacked shapes,

though the instruction will not be repeated.)

5. Repeat the stacking process, and the

attaching of front and back tabbed shapes

for tail . . .

. . . and wattle.

Take care that all stacked units have tabswhich remain un-glued and unattached.

6. Position and attach eye contrast circles

behind each body accent shape.

7. Position and attach front only accent shape

on the face side of the front body shape,

taking care to match up the heart slots exactly.

(The back accent shape is attached at the end

of construction. See Step 37.)

8. Prepare the dimensional heart box structure ("body")

and add-on strip shapes by bending back on all

perforation lines, except bend outer tabs forward.

9. Position and attach the accent shape

on top of the dimensional heart box main structure.

10. Position the add-on strip at top angle edge

of main structure, with strip's top tabs under

heart straight edges, align straight edge of body

overlapping strip's tabs to perforation lines,

and join the two angle edges.

11. Bend add-on strip ends inward to align

tab perf edge with next main structure straight edges

while tucking end tab under "boxing" edge,

and join top and tab seams.

12. Continue to form the dimensional heart structure

by bending boxing sides back to align short seam

straight edge to overlap adjacent wedge tab

until all segment seams have been completed

and the heart platform is done.

13. Position and insert heart wing tabs intocorresponding slots, work fully in so that heart

boxing edge seats next to body surface.

On backside, bend wing tabs outward and

attach in place.

bending back on all cross perforation lines,

and also bend tabs back.

15. Position center seam edges together,

then overlap straight edge over opposite tab

to perforation line, adjust and join seam.

16. Begin to join the boxing to body by aligning

the bottom body segment straight edge

with the boxing center tab perforation line,

then join tab to body backside.

17. Continue to bend boxing into position

to align and join the next tab to the next

segment of body until each segment is

joined in place.

NOTE it will be helpful to invert the assembly

onto a flat surface to enable finger pressure

to be applied along the tab seam area.

18. Identify the front end of the top boxing accent

by locating the half-circle notch on the front end edge.

top boxing, taking care to orient the accent front

end toward the top body boxing strip end

where the beak slots are located.

20. Add the front end of top boxing strip by

overlapping straight edge over tap, and joining.

21. Bend top segment to align with body top front

edge and join.

22. Position, align and join top boxing and front

panel edges.

23. Bend final segment into position to align

side edge flange tab with body edge segment

and also aligning boxing end edge with top tab

of bottom boxing strip, and glue both edges in place.

24. Prepare the beak shapes by bending back

on perforation lines.

25. Form the lower beak into a pyramid shapeby bending and tucking the tab under adjacent

straight edge and gluing seam.

26. Insert tabs of top beak shape into front body

boxing strip. On backside, bend tabs outward

and glue to inside boxing surface.

27. Position and attach lower beak directly

under upper beak, with inner edges close together.

28. Insert the comb stack tabs into the top boxingslots, then . . .

. . . on the inside, bend the tabs outward

and glue in place.

29. Insert the tail TOP tabs into the top body back

end slots, then pivot into position to insert back tabs

into back slots. Push the tail into position

until it is fully seated next to boxing. On the inside

bend the tabs outward and glue in place.

30. Prepare the interior support shapes by

bending side and bottom tabs forward.

Position shapes back to back and attach

the body portions only together.

31. Apply glue to inner side tab pairs, then . . .

. . position support into body cavity and

insert bottom tabs pair through bottom slot.

Straighten the support into its perpendicular

position to attach inner side tabs to backside

of front wall. Top edge should align at top boxing.

Secure inner side tabs in place.

Also bend bottom tabs outward on outside bottom

boxing and glue in place.

32. Add dab of glue under the top boxing flange

to attach it to top of upper support tabs.

33. The chicken will not sit upright without some

weight added.

Secure some kind of weight materials such as

these metal washers that are used for the model.

34. Place a number of washers into theback hull half and quick-glue (hot melt glue for example)

them in place. NOTE approx 8 washers were used.

35. Position the back body panel into position

to attach edges to wedge boxing strip tabs in

the same manner as the front panel was attached,

using . . .

. . . the trap doors to allow finger access in orderto make adjustments of tabs to edges

and apply necessary finger pressure.

36. To help trap doors attach in closed positions,

position and attach a circle halfway under

the bottom edge of opening, then . . .

. . . close door and glue door edge to connector tab.

37. Position and attach the back body accent

over the back body panel.

The Chicken Box Form is completed.

This country style chicken is so cute!

ReplyDelete