Oversize dimensional stylized dragonfly is composed

of stubby hex body with layered swirl overwing

and chicken wire under-wing

attached.

(Use a sharp blade for fine, detailed cut shapes.)

Tail post (reinforced

with a cut-to-size 5/16” wooden

dowel section) intersects body and acts as base

for

layered head base that holds hexagon dome “button” eyes.

(Alternate version

can use painted 1/2” wood balls for eyes,

glued onto alternate head base – see

top sample in thumbnail.)

Construct without leg sets, or attach

optional leg

pair sets under body.

Measures approx. 8.5” tall x 10” wingspan x 2” deep with

legs.

ASSEMBLY: 1. Identify and cut the shapes:

A tail post wrap B body stubby post wrap

C body post interior reinforcement hexagons (2)

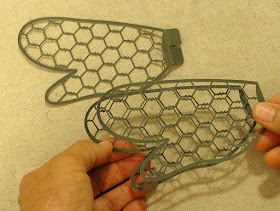

D under wing top layer with inner end tabs (l & r)

E under wing build up layers (2l & 2r)

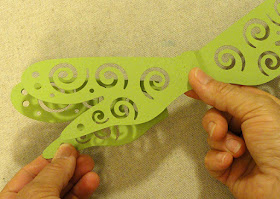

F over wing connected top pair

G over wing build up layers (2l & 2r)

H optional legs shape for build up (3 sets of 3 ea)

I optional legs front & back shapes with tabs

(3 sets of 2 ea)

J eye base with antennae (3)

K eye base front (3)

L eye hexagon buttons (2)

NOT SHOWN: opt. ball eye base shapes

(see Steps 2 & end of K); and opt. spacer strips to lift wings

one side of stack, and a tab back legs shape

to the opposite side of stack, taking care to line

up cut edges a precisely as possible.

the under wing over the build up, align and match

cut edges and glue together. Press under a flat

weight and allow to dry thoroughly.

(NOTE: if you work fast, steps B & C can be

completed together, then pressed and dried.)

the lower layers, align and glue together,

and press flat and allow to dry.

(See NOTE for under wings, which also applies here.)

the base shape with antennae, glue together,

and press flat.

(Steps J and K can be completed prior to

pressing.)

where the hex 'lid' perforation is, then . .

each end 'lid' inward. One way to get this

started is by pushing inward at the center of

the starburst cut lines with the tip of a tool such as

this spatula tool.

Then bend them fully back/inward on the perf

cuts for each tab. Repeat for both ends.

10. Form the shape into a tube to overlap the straight

edge to the perf line of the long flange tab opposite,

and glue in place.

One way to do this is to press the shape flat

to apply pressure along the length of the seam.

adjust to help the lid edges align with

the segment edges of the tube.

Complete one end then wait until the reinforcement

inserts are installed, as shown in

the next steps.

reinforcement (with adhesive applied to tabs)

to align with the tube walls, then . . .

place, adjust and apply pressure to ensure proper shape.

Direct the top triangle tabs of the hex opening

back under the top platform to allow them to stay

inside the boy post, as the tail post tip comes

through the opening. The final position of

the tail post is to be exposed approx. a scant 3/8".

the body post where tabs will attach to that face

of the hex tube. It should be spaced back from

the end of the body tube leaving a space

approx. 1/8" beyond the extended tab.

Push legs and body tube together so that

the legs thickness with glue can attach.

Ensure that the legs are as exactly perpendicular

and straight to the body as possible. Allow to dry.

21. Apply glue to the second legs unit as shown

in step 18, then position it so that the leg side

extensions cover up the pencil tick marks on

each side. Adjust to be perpendicular and straight,

then allow to dry.

side panels back so that "top" panel overlaps

the adjacent wedge tab, then continue to bend

back until the next side panel straight edge overlaps

the adjacent side tab to perforation line,

and glue in place.

Repeat for the remaining 5 seams.

the hex button over the eye base, "center" so that

the narrow margin all around is equal, then

apply pressure until adhered in place.

Repeat for the second eye.

fully attached in place. Repeat for the other bead eye.

A tail post wrap B body stubby post wrap

C body post interior reinforcement hexagons (2)

D under wing top layer with inner end tabs (l & r)

E under wing build up layers (2l & 2r)

F over wing connected top pair

G over wing build up layers (2l & 2r)

H optional legs shape for build up (3 sets of 3 ea)

I optional legs front & back shapes with tabs

(3 sets of 2 ea)

J eye base with antennae (3)

K eye base front (3)

L eye hexagon buttons (2)

NOT SHOWN: opt. ball eye base shapes

(see Steps 2 & end of K); and opt. spacer strips to lift wings

2. If you choose to use painted wooden ball eyes

variation, this is the product that was used for

the sample, 1/2" wooden beads purchased

from Hobby Lobby.

3. Prepare the shapes that will be layered and

glued together into built-up shapes so that

they can have time to dry thoroughly before

they will be used in the construction: under wings,

over wings, eye bases, optional legs.

A. Prepare the leg front and back layers by bending

the middle tabs forward.

B. For each of the 3 sets of legs, layer and glue

together three leg shapes (without the tabs),

taking care that cut edges line up as precisely

as possible.

C. Position and attach a tab front legs shape toone side of stack, and a tab back legs shape

to the opposite side of stack, taking care to line

up cut edges a precisely as possible.

Use a flat heavy weight such as the fabric-covered

re-purposed free weight shown here to immediately press

the glued-up shapes stack flat while the glue dries,

to help prevent curling or warping.

D. Prepare the under wings top layer shapes by

bending the inward end tabs (NOTE the shape shown

here is the option to be used with legs),

as "valley" folds.

E. Layer the two lower shapes for left and right

under wings and glue together, taking care that

all cut edges are lined up as precisely as possible

so the shapes appear as a single thickened shape.

Use a flat weight placed on top of the glued shapes

and allow to dry completely.

F. Position the corresponding top layer ofthe under wing over the build up, align and match

cut edges and glue together. Press under a flat

weight and allow to dry thoroughly.

(NOTE: if you work fast, steps B & C can be

completed together, then pressed and dried.)

G. Bend the middle perforations for the over wing

top layer shape, with the center-most perf lines

as "mountain" folds, and the outer as

"valley" folds.

H. Layer the left and right build up layers for

the upper wing so that all cut edges match,

then press flat under a weight and allow to dry.

I. Position and attach the upper wing overthe lower layers, align and glue together,

and press flat and allow to dry.

(See NOTE for under wings, which also applies here.)

J. Layer and glue together the eye base of choice

(for hex button eyes or for painted wood ball eyes).

Press under a flat weight and allow to dry.

K. Layer the eye base front layers on top ofthe base shape with antennae, glue together,

and press flat.

(Steps J and K can be completed prior to

pressing.)

(This image shows the same K step for

the ball eye option.)

4. Prepare the tail wrap tube by carefully bending back

on all long perforation lines, and . . .

. . . also bending back the end attached hexagon

"lid" and the tiny triangle tabs on BOTH ends.

5. Form the shape into a tube to overlap the long

straight edge over the opposite long tab flange

to the perforation line, and gluing in place.

NOTE: it will be helpful to insert a 5/16" wooden dowel

into the tube (wrap the shape around the tube)

to provide a press-against form so that

fingers can apply pressure up and down the tube

shape to complete an accurate seam along

the full length.

6. Prepare to measure the dowel for length so

that it can be cut to size by pushing the dowel

inward or outward until the 'top' end is even with

the top edge of the tube, where the hexagon 'lid'

is bent back. Next . . .

. . . carefully mark the opposite end of tubewhere the hex 'lid' perforation is, then . .

. . . remove the dowel and cut to size, taking care

to cut it a hair shorter than marked length.

6. Cut to size using hand saw, then reinsert

the dowel into the tube, adjusting until it is

centered.

7. Bend the triangle tabs inward, the hexagon

'lid' down into place, and glue all.

Repeat for second end hex lid and tabs.

8. Prepare the body tube in similar fashion to

the way the tail narrower tube was prepared

by bending on the perforation lines.

9. Bend the hex opening triangle tabs oneach end 'lid' inward. One way to get this

started is by pushing inward at the center of

the starburst cut lines with the tip of a tool such as

this spatula tool.

Then bend them fully back/inward on the perf

cuts for each tab. Repeat for both ends.

10. Form the shape into a tube to overlap the straight

edge to the perf line of the long flange tab opposite,

and glue in place.

One way to do this is to press the shape flat

to apply pressure along the length of the seam.

11. At the end, bend the tabs inward,

apply glue, then . . .

. . . bend the lid down into position andadjust to help the lid edges align with

the segment edges of the tube.

Complete one end then wait until the reinforcement

inserts are installed, as shown in

the next steps.

12. Prepare the body reinforcement hex inserts

by bending the outer tabs forward as shown . . .

. . . and also bending back the center tabs in similar

manner as was done for the ends of body tube.

Prepare two reinforcement shapes.

13. At open end of body tube, position the firstreinforcement (with adhesive applied to tabs)

to align with the tube walls, then . . .

. . . carefully slide it inside the tube, using the end

of a tool such as the spatula tube shown here,

and move it inward to the 1/3 position from

the opposite end. Take care that it remains

perpendicular to the tube walls. Once in position,

apply gentle pressure to ensure that it attaches.

14. Repeat for the second reinforcement,

pushing inward to the 2/3 position from opposite end

(or 1/3 in from open end).

15. Bend tabs inward, apply glue, bend lid intoplace, adjust and apply pressure to ensure proper shape.

16. Carefully insert one end of the tail post

into the bottom end of the body tube,

continue to push inward trying to sense how . . .

. . .the post is lining up with and passing through

the openings of each of the interior reinforcement

hex openings until it finally . . .

. . . is near the top end of the body post.Direct the top triangle tabs of the hex opening

back under the top platform to allow them to stay

inside the boy post, as the tail post tip comes

through the opening. The final position of

the tail post is to be exposed approx. a scant 3/8".

17. Apply the adhesive to help the body tube stay in

the desired place in TWO STEPS:

A) Push the body tube almost as high as it will go

to apply adhesive just below the bottom edge

(where body tube will eventually be return to

and where the hex opening tab may adhere);

B) Push the body tube downward to expose

a margin that will be hidden at the top to

apply adhesive there, then return the body post

to its final position to allow glue to grab.

18. Prepare the first leg unit to be attached in place

to the body tube by applying adhesive to the tabs

and also, as shown here, to the thickness of

the layers that extend upward on each side.

19. Position the legs unit on the "bottom" ofthe body post where tabs will attach to that face

of the hex tube. It should be spaced back from

the end of the body tube leaving a space

approx. 1/8" beyond the extended tab.

Push legs and body tube together so that

the legs thickness with glue can attach.

Ensure that the legs are as exactly perpendicular

and straight to the body as possible. Allow to dry.

NOTE: if omitting the legs, use the wings version

without the slot; skip steps 20-21, 23, and instead

simply position the wings in the approx. position

shown, wrapping the wings tab around body

in similar manner as shown hereafter.

20. Prepare to attach the middle legs unit by

using it as a measuring tool: position it directly

behind the front legs unit and hold in place . . .

. . . so that the slot (that will allow wing to fit

around middle leg) can be marked with a pencil tick.

Remove the wing, and repeat for the opposite side.

in step 18, then position it so that the leg side

extensions cover up the pencil tick marks on

each side. Adjust to be perpendicular and straight,

then allow to dry.

22. Apply adhesive to the wing tab first and second

segments, then . . .

. . . position the first (and second, shown here)

in place on the body with the slot fitting over

legs extension.

Apply pressure to attach.

23. Position and attach the back legs unit directly

behind the back edge of the wings tabs.

24. To help the under wing stay in desired position,

apply adhesive to the thickness edge at tab end,

then reposition the wing to allow that edge to

attach to the tab backside. Carefully hold in place

until the glue dries and holds completely.

Repeat for second wing.

25. Apply glue to the underside of the center and two side

segments of over wing top layer, then . . .

. . . position over the under wings position,

centered from top to bottom, align perforations

with the body tube perforations, and apply pressure

until fully joined.

26. To assist with the over wings to hold the correct

position, apply glue at the inner edge of wing

thickness, then re-position and hold in place

against the body tube until completely dry.

27. Prepare the eye hexagon button shapes by

bending back on all perforations for side panels,

side tabs, and . . .

. . . tiny wedge tabs between upper side panels.

28. To form the hexagon button, bend adjacentside panels back so that "top" panel overlaps

the adjacent wedge tab, then continue to bend

back until the next side panel straight edge overlaps

the adjacent side tab to perforation line,

and glue in place.

Repeat for the remaining 5 seams.

Bend the bottom tabs inward.

This is the appearance of the prepared button eye.

29. Apply glue to the underside tabs, then positionthe hex button over the eye base, "center" so that

the narrow margin all around is equal, then

apply pressure until adhered in place.

Repeat for the second eye.

30. Position the eyes/base unit over the tail post

extension above body tube, center, with lower edge

snugged up against the body tube, and attach.

For bead eyes: follow similar process to apply

glue to the inner edges of circle openings,

then position the painted bead in the circle window . . .

. . . apply pressure downward until bead isfully attached in place. Repeat for the other bead eye.

Position and attach the head base onto the tail post

in similar manner as for button eye unit.

Here is the completed dragon fly form.

No comments:

Post a Comment