Classic

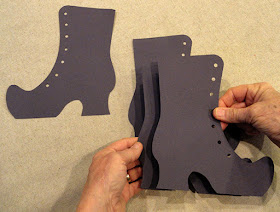

Irish Lady boot is composed of front and back

base panels that are layered for

thickness,

and attached to a shaped container structure between.

Front (and

duplicate back) boot has decorative detail,

including punch holes for specialty

lacing,

cuff with edge trim & heel accent with faux stitched cutouts,

toe arches

overlay, Celtic-style heart embellishment,

and layered small shamrock toe tip

charm

to add on one or both “fronts”.

Thread ribbon or lacing through punch

holes

then knot and bow for realism.

Add smaller “no Blarney ”

tag near side top for extra style.

Embellish heel with purchased florals,

twigs, leaves, etc.

Boot measures approx.7.5” tall x 6.75” wide

x 1.5” deep

when finished.

ASSEMBLY: 1. Identify & cut the shapes:

A left & right main accent boot base shapes

B left & right heel reinforcement accents

C left & right heel stack and soul trim shapes

D left & right side arches accent shapes

with soul trim

E left & right lacing bracket overlay shapes

F left & right cuff with edge trim shapes

G Celtic woven heart accents left & right

H toe "charm" shamrock base and overlay,

left & right

K boxing strips (back, underside, tongue)

L & N boot side base panels to layer for thickness

(3 each)

M right side "reversed" boot shape (with guide marks)

O left side "reversed" boot shape (with guide marks)

2. Locate and identify the guide mark cuts near

edges of "reversed" backside boot layers,

near the top back of boot . . .

. . . and at side and near back bottom.

3. Layer the built-up boot side panel shapeswith all cut edges lined up as precisely as possible

layered shapes under a flat heavy object such as

this re-purposed book, and allow to dry thoroughly.

This may required a few hours, but is recommended

as essential to avoid warping or curling.

5. Prepare the vessel structure shapes by bending

the front tabs back/inward.

6. Prepare the boxing strips by bending side tabs

back. Also bend back on the cross perforation lines

(these may be re-directed in next step).

to help identify which ends will attach as

assembly progresses. Here the back strip (left)

will be joined to the bottom/instep strip by matching

the circle cutouts.

8. Arrange the strips in order around the vessel side panel

to see where the cross-bends need to bend inward

or outward.

9. Prepare to join the first segment by aligning

the upper edge of back boxing strip at the back top

edge of vessel. Match top edges, first perf line

at vessel's first angle. Overlap straight vessel edge

across boxing segment tab/flange, and glue in place.

10. Bend the boxing strip second segment into position

to repeat step 9, adjust if necessary and glue in place.

11. Continue in the same process to bend remaining

segments of back boxing strip until it is fully attached.

NOTE that the boxing strip attachment seams of

first vessel side can be placed face-down on

flat surface to allow fingertip pressure to be applied

12. Position and attach the bottom strip circle symbol ends

by overlapping the straight edge to the tab's perforation line.

Continue the boxing strip segment seaming until

bottom strip's edges are all attached in place.

13. Position the tongue boxing strip bottom edge

with triangle tab into position, apply glue and tuck bottom

end under previous boxing edge, and glue in place.

14. Continue in same manner to position and attach

tongue edges to vessel's tabs in same manner.

15. Repeat the alignment and joining process for

the second (left here) vessel side panel . . .

. . . until all tabs/flanges are attached in place . . .

. . . to complete the vessel.

16. Assemble the accent boot panels (left & right).

A. position and attach lacing placket, heel stack,

loopy trim overlay, sole strips to main boot shape.

B. position and attach cuff trim to cuff shape.

C. layer and attach shamrock charm shapes.

D. position and attach cuff unit with upper and back

edges aligned.

E. position and attach the heel accent and Celtic heart.

17. Position the boot accent assembly onto the corresponding

built-up boot stack, with offset edges all around . . .

. . . except bottom "sole" edges match up. Glue in place.

(Complete both left & right panels.)

18. Apply quick-grab glue (such as the Fabri-Tac

adhesive shown here) to the vessel side panels, then . . .

. . . position and attach the vessel shape on the underside

of corresponding boot base stack, using cut-in guide marks

to help align vessel back top edge . . .

. . . also lining up bottom edges exactly.

19. Complete ribbon or twine lacing as desired.

Ribbon for the model is about 1.75 yds long.

Here, the ribbon is threaded onto a large-eye darning needle

to assist with ribbon threading.

20. Add decorative brads or nail studs to shamrock

charms at punch holes.

Position and attach each at top tip (low enough to

hide brad prongs, if necessary).

Here is the completed boot vessel.

Here is a slightly more-forward view.

21. As preferred, add other embellishments to

completed boot, including purchased florals,

ribbon loops, tag, and wooden beads or balls

on ribbon ends.

No comments:

Post a Comment