Halloween decoration

imitates cut wood components.

Hour glass-shaped witch body is built as box lid and

base

that fit snugly together, held up by square post

reinforced with .25”

diam. wood dowel inside.

Layered-for-thickness arms, dangling legs and

miniature pumpkin are attached with thick

craft wire twists or “D” rings.

Star

box platform (lid and base) holds post.

Create the figure’s wig by wrapping

twine around

knitting needle or dowel, setting with craft glue "wash",

removing coils and tying into tails, to finally arrange

and attach to

head top, sides and back.

Top off with miniature witch’s hat.

Figure display

measures approx. 4.25” wide x

4.25” deep x 10.75” tall when assembled.

ASSEMBLY: 1. Identify and cut the shapes:

For the star base:

A base lid top panel B lid accent star

C lid boxing short & D lid boxing long strips (2)

E lid & K base collar to stabilize post (4-5 each)

F base star G base star "hollow" foot

H base boxing short & I base boxing long strips (2)

J base interior strut (riser)

L post strip

For the witch figure:

M lid body front panel N lid lower body boxing

O lid head boxing P neck brace

Q base body back panel R base lower body boxing

S base head boxing T base lower center collar (4-5)

U base lower body triangle strut riser (2)

V base wire hole strut riser (4)

W right arm (7-8) and X left arm (7-8) to stack

Y right leg (7-8) and Z left leg (7-8) to stack

AA body front accents overlays:

head, body front, arms, hands, stars to inset,

legs shoes, shoe bands, shoe buttons

BB pumpkin accent shapes: stem, bottom,

middle (with contrast inset circle), top

CC pumpkin base to layer: front, back, interior (6-7)

For hat: DD crown cone

EE crown triangle accent (6)

FF brim with wavy edge

(not shown: opt. crown underlay to hide assembly seam)

2. As preliminary tasks that would allow stacked

and glued-up shapes to be drying,

complete steps 2-8) (which are somewhat out of

order from logical assembly progression):

A) stack and glue together the left set and right set

of arm shapes, taking care as each shape is layered

that ALL cut edges and hole punches are aligned

as precisely as possible, (here and throughout).

On top of each left or right stack, position the upper

arm shape with edges aligned to stack, then

position and attach hand shape.

Once stacked and glued, immediately place under

a heavy flat object such as this thick book (possibly

with something heavy placed on top as well) and

allow the shape to be pressed flat until completely dry.

This may take several hours or overnight. Pressing

will help avoid warping or curling of layered shapes

glued up with liquid adhesive.

B) Prepare the legs in similar fashion to arms,

stacking the duplicated shapes and aligning cut

edges precisely, then press under heavy flat weight

while glue dries completely.

Here is the leg stack with patterned front shape

and shoe shapes.

C) Complete the arms by position and attaching

the upper arm, hand and stars in the arm depressions.

Complete the legs by position and attaching

the patterned front shape, shoe with band and

button on top in positions shown in base shapes.

D) Position as stack and glue together the body base

bottom boxing collars that will help hold post in position,

and press under weight til dry.

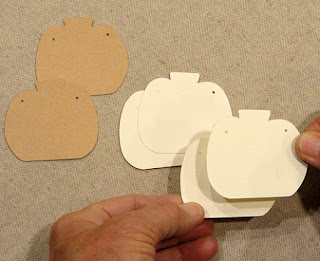

E) Layer and attach pumpkin shapes (shown for

sample project . . .

. . . with interior cream and front, back

as kraft tan), aligning cut edges and wire hole

cutouts precisely, then press under weight til dry.

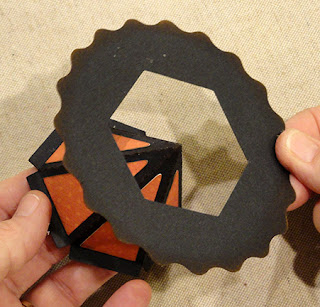

F) Identify the star platform lid front shape by

locating the letter 'F' cut symbol, then . . .

. . . position, centered, the contrast accent star panel

on to, with center post hole cutouts aligned,

and press until dry.

G) Position the hollow star "foot" shape on top of

star base panel, with outer edges slightly offset,

attach, then press until dry.

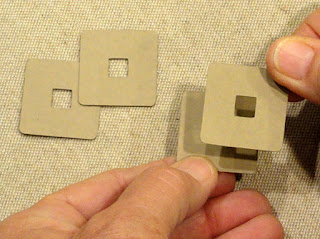

H) Position and attach the collar shapes for each

of TWO collar stacks that will help reinforce platform

opening to hold post.

Position and attach each collar on the underside of

the star platform LID and BASE main star shapes.

Press under weight until dry.

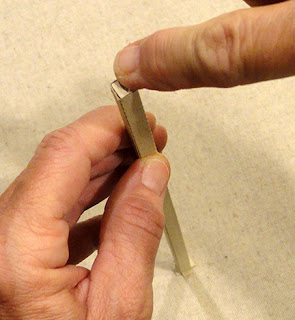

3. Prepare the long post strip shape by carefully

bending back slightly along perforation lines for

narrow panels and long flange, and also end 'cap'.

4. Form the strip into a tube to overlap the straight

long edge across the opposite long flange to

perforation line to join seam.

NOTE that the post shape can be pressed FLAT

in order to apply fingertip pressure up and down

the entire length to ensure that the seam is fully joined.

5. Open the tube shape into its non-flat shape.

Insert .25" diam wood dowel into tube (NOTE that

the post shape in final file version does not include

tabs at top edge as shown in this assembly photo) . . .

. . . and slide fully in so that the lead edge is even

with the end edges of tube (NOTE that in this image

the bottom 'cap' panel is opened and out of the way).

Mark the cut length of dowel with fine tip pencil

at opposite tube end. Remove dowel and cut

to length at mark.

6. Re-insert dowel into tube where adhesive

has been applied inside both ends, and push

fully in so that dowel ends are even with tube

cut edges.

7. Prepare the hat crown shape by bending back

on each of cone panel perforation lines, and

bending forward at bottom edge tabs.

8. Position and attach crown accent triangle shapes

onto front of crown centered within perforation lines,

and with bottom straight edge along bottom tab perf

lines, then press flat until dry.

9. Identify the body/head LID front by locating the 'F'

symbol cut into the panel - set it aside while

the BASE body/head is assembled. Also locate

the dash guidelines roughly opposite the wire holes

for arms and legs on both LID and BASE.

10. Identify the BASE lower and head boxing strips

by locating the tiny hole symbols cut into the center

segments.

Add some back curl to the multi-tab portions on

each side of center of lower boxing strip, using a rod

tool such as this narrow-diameter dowel. Then . . .

. . . bend the 'solid' and ultra-narrow tabs back

all along the strip. (NOTE it is easier to

add curl before the tabs are bent back.

11. Position BASE bottom center edge along corresponding

center portion of the body boxing strip, using

the dash cut guide marks (body) aligned with guide

perf lines on boxing strips to assist centering.

Overlap body edge across 'whole' tab to perf line

and join seam.

12. Shape the first end of boxing strip around

panel edge to line up tab at top of strip exactly

at the end of edge at 'valley' between body and

head and . . .

. . . attach whole tab under body edge. Then

shape the multi-tabs edge to match the body panel

cut edge and glue those tabs in place at edge.

13. Repeat to position, shape and attach the second

boxing side for the BASE.

To assist with seam attachment, place the assembly

face down on flat work surface and use fingertip pressure

around the boxing interior to press tabs flat

and complete attachment.

13. Position the reinforcement post collar on bottom

center boxing strip inside edge, matching post

opening edges as precisely as possible,

and glue in place.

14. Prepare the head boxing strip in similar manner

to body boxing strip, adding curl at multi-tab curve

segment, then bending whole and narrow teeth tabs back.

15. Position appropriate head boxing end tab

behind end of body boxing top end edge

and attach.

16. Position center boxing segment at panel

top center where guide marks indicate, and attach.

Then . . .

. . . form and shape the multi-tab curve portion of

boxing to fit and match the head panel edge

then glue in place.

17. Repeat the process for the second side of head

with boxing, positioning, forming and attaching.

Finally, tuck the end tab behind the body boxing

top edge and glue in place to complete boxing

attachment all around.

18. Prepare the interior supports for the BASE:

A) wire hole three-panel supports - bending back

at vertical perforation lines, and bend top and

bottom tabs forward.

B) triangle side body supports (2) - bend back

at vertical perforations, and bend end tab and

back, edge tab flanges forward.

Form strip into a triangle and join with end tab

overlapping and attaching at opposite end edge.

C) neck bridge - bend all tabs back.

19. Position the neck bridge at narrowest position

with end tab perf lines aligning at bend crease

and attaching there, with bottom flange being

glued to backside of BASE main panel wall.

(Top flange will attach to LID when box is closed, later.)

20. Position and attach the triangle supports on each

side of center body cavity, long edges parallel . . .

. . . taking care that the channel where

the post will be inserted remains free and

clear - demonstrated in this photo where

the post is laid across the center.

21. Form the four wire supports into arcs

then position so they surround the still-open

area below or above each of the wire holes.

(NOTE these will allow wire to be positioned

and "tightened" as much as cardstock will allow.)

22. Complete the LID boxing in same manner

as the BASE boxing was assembled.

23. Position and attach the accent front body shape

over the front of LID, side and bottom edges

matching. Position and attach the head/face accent

above the body accent in similar manner (attach

contrast circle behind face features if LID does not

provide the appropriate contrast for eyes, mouth).

Position and attach star accents in recesses.

24. Prepare to close the LID over the BASE by

applying glue to all the interior support upper tabs

and flanges.

Position the LID over BASE and slide the two

together completely. Spread the LID wall away

from the BASE wall to apply glue between, then . . .

. . . apply pressure all around to join LID to BASE.

If possible, position heavy objects around drying

head/body box edges to apply inward pressure,

especially at neck indentation.

25. Prepare the 'D' rings to attach legs to body by

shaping 16 gauge wire around a wide rod object

like this 1.25" diam. dowel, then further shaping . . .

. . . upper corners with narrower dowel.

Target D ring size is approx. 1" wide x .8" tall -

needs to be tall enough to allow legs to swing,

and wide enough to span body thickness.

Overlap wire ends across center top, then

cut at center.

26. Divide the ring at top to allow threading of

each leg onto ring and slide to bottom center.

27. Thread D ring ends through body wire holes

on front . . .

. . . and back so that cut ends meet invisibly

inside body box.

Legs should dangle free below body bottom panel . . .

. . . as shown here.

28. Assemble the pumpkin accent by layering

the middle contour over the bottom contour . . .

. . . using the bottom contour edges near the stem

to assist with top alignment, with bottom straight

edges even. Position and attach the contrast disc

into the circular depression.

29. Position the face layer over the assembly

and attach. Position and attach stem at top.

Position and attach the pumpkin accent assembly

onto the stacked base shape completed earlier.

30. Prepare a length of wire by bending into a 'U'

shape that matches the width of the pumpkin's

wire holes . . .

. . . then thread a hand onto each arm of wire 'U'

then thread pumpkin onto ends.

Use needle-nose pliers to twist a curl into wire

ends just above surface of pumpkin, then trim

excess ends.

Here is a back view of the arms & pumpkin assembly.

Apply clear nail polish or clear-drying glue to

wire cut ends to make them less sharp.

31. Prepare two lengths of wire with a twisted

curl at one (front) end. Thread straight end

through arm wire hole, then . . .

. . . thread through body wire hole.

Repeat for the second arm.

On back, carefully twist a curl as close to

the back panel as feasible.

32. Prepare to complete the star platform by identifying

the BASE boxing strips with the half-circle "bite" cut outs

at the ends tabs of each.

33. Prepare the boxing strips for LID by bending back

at the shaped tab perforation lines (points), and forward

at the end tabs or center perforation lines (valleys).

34. Join the boxing strips end to end by overlapping

the plain end across the end tab to perforation lines,

ensuring that bottom but edges remain on common

straight line, and complete seams. Leave the final

end seam unattached until later.

35. Begin attaching the LID boxing strip to front

star panel assembly by aligning the plain end at

"valley" in one selected position. Overlap star edge

across flange, adjust and glue in place.

36. Bend the next TWO segments into position along

the next two edges of star, adjust and glue in place.

Continue around remaining star edges, until final

segment, which is positioned in the same motion

as final end tab to complete the perimeter.

37. Complete the star BASE in same manner.

38. Prepare the interior support pentagram strip

by bending back on vertical perf lines, and bending

tabs back. Position and attach inside BASE,

taking care that it seats around post collar.

39. Apply glue to the exposed support tabs,

then fit the LID over the BASE and slide together fully.

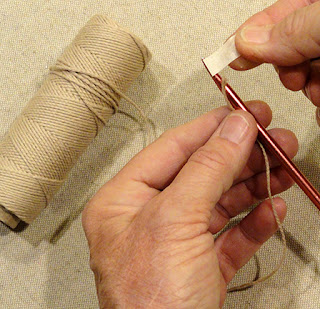

40. Prepare twine hair as follows:

A) Tape end of twine to the top of a knitting needle or

equivalent that will produce coils.

B) wind the twine around the tool in snugly placed

coils and continue to wrap all the way to the bottom.

(NOTE: the model shown uses 5 needle loads of

approx. 8.5" long each.)

C) at the end of the coil, trim the twin end and

attach in place with a second tiny tape strip.

D) Mix a glue wash of 1:1 parts white (clear drying)

craft glue and water. Use a foam or other brush

to paint the wash thoroughly over the entire coil,

soaking the twine. Allow to dry.

E) slide the coils off the needle and . . .

. . . carefully pull the coils apart until separated.

Try NOT to pull the coils any straighter than necessary.

41. Determine the length of the wig over the head shape

and down far enough on each side to create pig tails.

NOTE: for the sample the wig loops spanned

approx. 8" - or 4" on each side of centerline.

42. Arrange the coils in a pile with loop ends in

determined or recommended length wig as shown.

If possible, machine stitch across the center with

matching color thread and tiny stitches. Tea dye

or otherwise modify coils color, if desired.

43. Tie the tails with contrast twine.

Arrange the wig over the head boxing, adjust

and glue in place.

At the head back, scrunch the twine curls inward

toward center to cover the panel, and glue.

If desired, trim the loop ends straight across

at bottom of pig tails, matching length at each side.

44. Form the hat crown into a cone to overlap straight

edge to overlap flange tab opposite, and join seam.

NOTE it may be helpful to insert a pencil or narrow

rod tool inside the cone behind the seam to

provide a press-against surface.

45. Apply glue to the upward surface of crown

tabs, then slip the brim shape face-down over

crown point and slide down into position . . .

. . . to seat snugly in place at tab perforations.

Press to secure all around. If desired, tie a small

ribbon bow to attach to center front.

46. Test the hat on witch girl's head and curls,

make adjustments as needed, then remove hat

and apply glue on the inside rim of crown.

Re-position hat and hold in position until secure.

47. Prepare for final assembly on platform and post

by using the end of a tool such as this spatula

to press open the lower post opening at bottom

of body LID.

48. Apply glue inside upper and lower post hole openings

of star platform. Insert post bottom end (with 'cap') into

top opening and push down, fishing around until

bottom end finds the bottom collar and push through

until 'cap' is flush with BASE bottom panel edges.

(NOTE: if the post seems steady enough without glue,

the post, platform and witch can be disassembled

for storage.)

49. Locate the front of platform, the star point that

is directly in front of SQUARE post opening,

then slide that face of the post into body post opening . . .

. . . in parallel orientation, so witch faces forward.

Here is the finished witch girl on platform.

No comments:

Post a Comment