Six-sided candle is assembled as

outer and inner

tubes that fit together

to provide strength and sturdiness.

Top has a recess

that accepts a

"standard" LED tea light with a punch-hole cover

"standard" LED tea light with a punch-hole cover

that fits over the

flame tip to conceal

the purchased tea light's power base.

Measures approx. 2.5" deep x

3" wide in three sizes

from 9" to 6.375" tall when

assembled.

Display as a single, or group as an ensemble.

The assembly model used in this tutorial

will be the large candle. Except for the size

of the hull, its accents, and base insert shapes,

construction is identical for all three sizes.

ASSEMBLY: 1. Identify and cut the shapes:

A main candle hull

B hull top recess rim gluing ring

C hull top "cover" hexagon

D tea light "dome" cover

E hull side accent shapes (6)

F base insert main

G optional base bottom "cover"

H base top opening reinforcement collar

NOT SHOWN is the alternate paper "flame"

presentation with its own dome shape.

This alternative can be viewed in assembly

of roman candle, steps 11-14 or 15, at

this LINK.

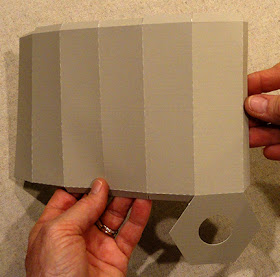

2. Prepare the main hull shape by bending

BACK on all vertical perforation lines,

on bottom at rim tabs, and on second

perforation down from top edge; also bend

forward at the topmost ledge tabs.

This image shows closeup how the top flangesand rim tabs will be bent into position to

eventually hold the ring and cover where

tea light will rest.

Wider flange tabs fold to the inside of the hull,

and narrower at-the-edge rim tabs bend inward

toward the center to form a ledge.

4. Position and attach the accent shapes

in each of the 6 hull panels, offset .1 from all

edges or panel perforation lines, as shown.

5. Bend 5 of the top edge flanges into placeand glue ONLY the flanges into place to

the backside of the hull shape, leaving the ledge

tabs free. Also glue 5 bottom rim tabs in place.

NOTE that the flange and tab opposite the long

side seam flange are the ones left un-glued.

6. Form the hull into a tube to bring the straight

side edge to overlap the opposite flange,

adjust so that top and bottom panel edges

line up properly, then glue the seam.

NOTE that the symmetrical shape of the hull

allows it to be flattened to apply finger pressure

along the seam being joined.

(Re-adjust once the seam is done back

to the hexagon tube shape.)

7. Bend the final rim flange and bottom rim tab

inward to proper positions and glue in place

as was done for similar tabs in step 5.

8. Bend all ledge tabs at perpendicular angle

toward center of tube interior, then apply

adhesive to the upper surface of the rims

all around. Then . . .

. . . insert the rim ring into the opening

to rest on the ledge tabs, adjusting the hexagon

shape as needed to exactly match the ring edges.

Apply finger-tips pressure all around the rim ring

to attach securely in place.

9. Position and attach the cover hexagon insertinto the top recess.

10. Prepare the base insert in similar fashion

to the bending prep done for hull, except

at the top rim edge there are only simple tabs,

and one of the bottom tabs has been replaced

by the bottom hex finger hole panel.

11. Bend the top edge rim tabs back and gluein place, except leave the end tab opposite

the side seam flange un-glued at this point,

in similar fashion as was done for main hull

in step 5.

12. Form the insert into a tube and complete

the side seam in similar fashion as for

hull in step 6.

13. At insert bottom, bend the tabs inward

at perpendicular angle, apply adhesive to

the outer face of tabs, then bend the bottom

hex panel into position, adjust so that

hex edges align as precisely as possible

at the tab perforations, then . . .

. . . use finger hole

to reach inside to apply pressure around

the edges to secure the tabs to hex panel.

14. Prepare the base collar shape by bendingall edge flanges upward.

15. Apply adhesive to the backside of the flanges,

then position the collar into the base's top opening,

and push tabs down equally until . . .

. . . top edges are even with the rim tab fold edges,

then apply finger pressure all around to secure

in place.

16. Insert the collar end of base into the

bottom opening of the main hull shape.

NOTE that this should be a very tight fit

and it may require the assistance of a thin blade

style tool such as a paper craft spatula to

get the final corner to insert as required.

Slide the insert in to within 3.4" or so, then pause to apply adhesive to

the exposed hull faces, then . . .

. . . push the insert in fully so that bottom

is flush with bottom of hull.

17. Once hull-base connection gluing is secure,

position and attach the optional bottom hex

cover in place.

18. Prepare the tea light dome insert by

bending back all edge flanges.

19. Push the flame tip through the opening

and allow the cross cuts to flex so that circle

opening rests as flush to power housing

as possible.

Push edge flanges toward the center, theninsert the tea light into the top recess

and gently push downward so that it rests

fully onto the hexagon platform.

There will be approx. 1/8" interior rim exposed.

Here is the completed candle stick with

tea light in place.

Activate the tea light flame by removing

the dome and switching on the light, then . . .

replace the dome as directed at the beginning

of this step.

Shown here is the trio of varied size

tea light candles available to create

an ensemble. Or use your imagination

to configure a mantle or centerpiece

gradated row, menorah or other presentation.

Amazing - now my fingers are itching again :-D

ReplyDelete