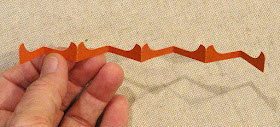

Cut multiple “thankful” word

shapes and glue into

a thick stack so it appears as a wrought iron cut-out.

Construct the “plank” box lid, then base and add

built-up platform for thickness and

weight.

Square tube “posts” extend from plank to attach

to backside of word

letters.

Display measures approx. 11.7” long (word) x

2.5” deep (plank) x 6”

tall.

Optional taller post shape can increase overall height to 8”.)

(Requires 12x12 cutting capacity and

4-5 sheets of cardstock plus accent paper.)

ASSEMBLY: 1. Identify and cut the shapes:

A thankful word cuts (6-7 to stack for thickness)

B post shapes C collar post anchors (2 sets 4-5 ea.)

D box LID E box BASE

F base bottom platform stack (4 to stack for thickness)

G accent panels for LID

H interior "strut" supports (attach inside base)

adding them one by one to form a stack, taking care

to align ALL cut edges as precisely as possible.

HINT: It may be helpful to stack and glue up 3-4

to begin with, then press and cure for 1-2 hours. Then

adjusting and confirming most precise positioning

of glue-up, press under a heavy, flat weight, such

as one large wood plank as shown here, or

several large book volumes, etc., until thoroughly

dried - this may require several hours or over night.

3. Position and glue platform rectangles into a stack,

3. Position and glue platform rectangles into a stack,

then press flat under weight until thoroughly dried.

perforation lines, including the top end "cap" square

and tiny wedge tabs. NOTE that the post shape

includes a diagonal interior flange to provide strength

and help keep the post straight - marked with

into final position to close the tube. Hold until secure.

Bend top tabs inward, apply glue and bend top

Bend top tabs inward, apply glue and bend top

"cap" into position, square up with walls, and hold

and glue together, taking care that interior square

cut out edges are aligned as precisely as possible.

One way to ensure the collar opening is precise

is to use one of the assembled posts to insert

through the opening.

Then press flat with weight until thoroughly dried.7. Prepare the BASE "tray" by bending back on

all perforation lines for center panel, side walls and

end tabs. NOTE that the BASE tray is distinguishable

from LID tray by a 'B' cut into one end flange.

8. Turn the tray face down, then position and attach

the post end collars so that the interior squares of

collars and base align precisely. Press until dried.

9. Turn the base tray face up again, then position the bottom

platform assembly on bottom with edges aligned with

center panel perforations, and glue in place.

Press under heavy weight until thoroughly dried.

10. When glued up assembly of base is completed

and dried, complete the corner seams by bending

adjacent walls into position, with straight edge

overlapping tab to perf line, then gluing.

11. Prepare the LID shape by bending back on

all perforation lines in similar manner to BASE.

12. Position and attach accent shapes offset slightly

from panel edges centered with even narrow margins

all around. For center panel, take care that post holes

of LID panel are centered within accent hole cut outs.

Press flat until dried.

13. Bend adjacent walls back to join corner seams.

14. Prepare internal support "strut" sections by

bending tabs forward, and bending back at

vertical short perforation lines within strips,

and forward at end tab of left strips.

NOTE that pairs of strips will be joined into one longer

strut, one strip that includes the inward end tab.

One of the pairs is the upward slot strut, shown below

with the circle cut outs within end tab and bottom tab;

and the other pair for the downward slot strut.

15. Join the pairs into their longer forms by overlapping

the straight end across the opposite end tab to

perforation, adjusting so that top and bottom edges

align, then joining seam.

16. Rotate one of the strut assemblies so that the two

create a 'W' (top) and mirror image 'M' as shown,

with tabs at bottom resting on work surface.

17. Position the upward slot strut (with circle cutouts)

above the other strut, adjust so that slots align,

then carefully slot the two together so that they

both sit flat on work surface.

18. Apply glue to the downward surface of strut tabs,

then position inside BASE tray with ends extended

into corners, "window" openings surrounding collars.

FINISHING

19. "Fill" each of the collar wells (center square cutouts)

with adhesive - quick grab glue is recommended.

Then immediately . . .

. . . place the LID over the BASE to close the plank.

(This should be a tight fit, so maneuver lid straight on.)

Push down completely into position, and quickly . . .

. . . add adhesive between each LID wall and

BASE wall. Press together to true up wall layers.

Finally, insert each post "open" end through lid top

panel down so that the bottom end seats within

the collar "well" inside and at bottom of BASE.

Repeat for second post.

SUGGESTION: at this point in assembly, it may

be helpful to place straight edge props such as

heavy book volume spines or flat-sided household

items against walls to help with joining of wall layers

and leave in place until wall joints are dry.

20. "Dry fit" the positioning of thankful word cut assembly

over the post ends, so that front post is hidden behind

back 'leg' of 'h' and back post is hidden behind

back 'leg' of 'u', as shown below.

Posts should be approx. generous 1/4" below top edges

of letters. Apply quick grab glue to top portion of posts

where word will overlap, then position and attach.

Adjust final positioning so that the word cut is

"parallel" to plank (as well as uneven nature of

word shape may suggest), then prop or hold in place

until secure.

Here is the final word on posts & plank display.