Use heavy card stock plus card or paper accents

to create sturdy box with flap lid.

Dimensional outer and compartment walls

slot or fold together with tabs and flanges.

Concealed "super magnet

discs" plus 19/32" washers

hold the lid flap in place

against front wall.

Front "label pull" accent assembly component included,

or use metal label pull hardware from "Holtz".

small scale scissors, measuring tape, short pin cushion,

bobbins and thread, etc.

Specially-sized front compartment accepts

coordinated design "bobbins 3d tote".

Measures approx. 7.5" wide x 7.5" deep x 2.5" tall.

ASSEMBLY: 1. Identify and cut the shapes:

(walls A & B shown with outer and rim accents)

A back wall (includes arrow symbol in margin)

A wall front (includes circle symbol in margin)

B left wall ('L') B right wall ('R')

C interior wall D interior wall

E interior wall

F interior wall with strip with downward shaping

(use this F wall if incorporating the bobbin tote)

G box base H box base bottom cover

I front wall inside magnet placement guide

and reinforcement

J box lid with main and flap accent shapes

K under-lid reinforcement frames (3-4)

L front under-flap washer shapes (2)

Not shown: solid under-flap cover

M label pull (paper) hardware and label

reverse the base shape on a flat surface

and apply pressure from the front over the tabs

to fully secure.

and attaching the outer wall accent shape

and the rim shape as shown.

NOTE that the rims of the A shapes will NOT

have the mitered ends; center it just the same

and the B wall overlaps should end up right where

the miter cut end edges are.

angle of the tab, and be centered so that the

mitered corner edge intersects exactly at

the center of the Base corner.

Apply pressure all along the flange tab edge

as the glue is drying and grabbing so that

this snug position is maintained ALL ALONG

the entire edge, and particularly at CORNERS.

front and back perforation lines.

Position and attach the reinforcement unit

on the backside of the Lid shape, matching

outer cut edges exactly.

25. Position and attach the washers inside

the reinforcement circle cutouts using the

appropriately strong, quick grab glue.

26. Eventjually complete the Lid flap construction

- after Step 32 - by positioning and attaching

the whole flap reinforcement

shape over the backside to hide the washer

construction.

(walls A & B shown with outer and rim accents)

A back wall (includes arrow symbol in margin)

A wall front (includes circle symbol in margin)

B left wall ('L') B right wall ('R')

C interior wall D interior wall

E interior wall

F interior wall with strip with downward shaping

(use this F wall if incorporating the bobbin tote)

G box base H box base bottom cover

I front wall inside magnet placement guide

and reinforcement

J box lid with main and flap accent shapes

K under-lid reinforcement frames (3-4)

L front under-flap washer shapes (2)

Not shown: solid under-flap cover

M label pull (paper) hardware and label

2. Identify the positioning of the outer (A & B)

and interior (C-F) walls by locating

the line of slots (exterior) or paired lines of slots

into which bottom tabs will insert.

This diagram of the base shape shows

wall positions.

3. Prepare the walls by bending back (downward)

at perforations, and also bend tabs outward.

(NOTE: it may be an equally good choice to leave

the tabs un-bent so that they may more easily

be inserted into slots, then bend outward

(valley fold) after that.)

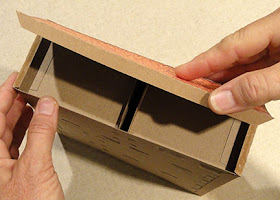

4. Begin with Wall D, insert tabs into slots

on the face side of the BASE shape . . .

. . . then bend tabs outward and glue in place

on the base shape backside.

NOTE: make sure that the tabs remain fully

inserted so that the tab perf lines fall

right at the slot edge.

Once the tabs adhesive begins to grab,reverse the base shape on a flat surface

and apply pressure from the front over the tabs

to fully secure.

5. Prepare modified Wall F (if using this version)

by bending walls back as for other wall shapes,

but also bending cutout tabs inward, and

rim tabs inward.

6. Apply adhesive to the opening tabs,

then position the strip (bend upward at

strip perforations) into place. First attach

the strip ends to the rim tabs, then to the

remaining flange tabs.

It may be helpful to position a tool such as

this colored pencil shaft behind each section

of the added wall and tabs to provide

a "press against" surface to help secure in place.

7. Position Wall F and insert bottom tabs into

corresponding slots in base. Bend tabs back

and glue to the backside of the base shape.

8. Position Wall E at its corresponding slots,

then slide it into position by fitting the cutout

around the end of Wall F as shown.

Insert tabs into base, bend outward on

backside, attach tabs as previously done.

9. Once Wall E is secure, adjust it slightly away

from Wall F to apply a dab of adhesive

on F's rim where the underside of E's rim

will return into position.

Slide E back into place and apply pressure

there to secure.

10. Position Wall C in same manner,

slotting wall cutouts over Walls D & E, securing tabs,

applying dab of glue under intersection, etc.

as was done in step 9 above.

11. Prepare outer Walls A and B by positioningand attaching the outer wall accent shape

and the rim shape as shown.

NOTE that the rims of the A shapes will NOT

have the mitered ends; center it just the same

and the B wall overlaps should end up right where

the miter cut end edges are.

12. Further prepare the Wall A front by

positioning and attaching the magnet positioning

guide shape, on the underside

of the outside (non-cutout) front wall,

centered between outer side cut edges

as well as between rim perforation line

and bottom flange tab perforation line.

13. Position and glue in place (hot glue

or other substantial glue recommended)

a super magnet disc in each of the

circle cutouts.

NOTE these magnets will correspond

with the metal washers placed in the

lid front flap layers to provide the

magnetic snap closure, if desired.

14. Position one side Wall B (Left shown here)

into appropriate position, insert inner wall

bottom tabs into corresponding slots,

with wall cutouts fit around walls,

and connection tabs at the top

of the wall cutout area bent back.

On Base backside, bend tabs toward center

and glue in place.

15. On the backside of the B wall assembly,

apply adhesive at the end of the rim of the

protruding wall shape so that the connection tab

there can bond. Allow that bond to occur

naturally when the outer wall is completely in position.

16. Fold the outer wall portion of Wall B unit

into position to wrap the bottom flange inward

at the corresponding Base edge.

The Base edge should seat snugly into the perforationangle of the tab, and be centered so that the

mitered corner edge intersects exactly at

the center of the Base corner.

Apply pressure all along the flange tab edge

as the glue is drying and grabbing so that

this snug position is maintained ALL ALONG

the entire edge, and particularly at CORNERS.

17. Position and attach the second Wall B unit

in similar manner.

18. Position first Wall A similarly, but also

slot the inner wall end flange tabs of each B into

the slots in A as shown here. When in place,

bend the tabs toward the center and attach

in place, applying pressure to the area

from the inside of the box at corresponding

corners.

19. Bend end tabs of Wall Bs inward and

apply adhesive.

Bend the outer wall portion of Wall A into

position to wrap the flange around Base edge . . .

. . .as previously done for Wall Bs.

Apply pressure along flange as before, and also . . .

along wall ends to secure B end tabs

as well as possible from the outside. This process

may require a few extra moments to assure

a good seam along all three sides involved.

20. Attach second Wall A in similar manner.

21. Position and attach the bottom cover

over the exposed construction on the base.

22. Prepare the LID shape by positioning

and attaching the offset center square accent

and both flap offset accent shapes.

23. Prepare the LID front flap washer reinforcement

shapes by layering and attaching the two

flap shapes with circle cutouts.

24. Prepare the Lid shape by bending back atfront and back perforation lines.

Position and attach the reinforcement unit

on the backside of the Lid shape, matching

outer cut edges exactly.

25. Position and attach the washers inside

the reinforcement circle cutouts using the

appropriately strong, quick grab glue.

26. Eventjually complete the Lid flap construction

- after Step 32 - by positioning and attaching

the whole flap reinforcement

shape over the backside to hide the washer

construction.

27. Prepare the under-lid buildup frame shapes

by layering and attaching carefully to make sure

all outer edges line up as exactly as possible.

Also, use heavy flat weight (if possible) to ensure

that there is no warping of this buildup shape

while adhesive is drying.

NOTE: this build up frame will correspond with

the inner rim edge of the outer box walls

to help secure the lid in place when closed.

28. Position the frame onto the backside

of the Lid, centered from side to side

and from front to back, and securely

attach in place. Use heavy weights again.

29. Prepare the paper label tab "hardware"

by layering and attaching the under carrier shapes

as shown here.

30. Attach the under-shapes to the backside of

the main label bracket, matching side and

lower edges exactly.

31. Bend the tab back at the top of the

lower bracket reinforcement shape, then

attach the "pull" portion of main shape and

lower shapes with edges matched

(leave tab free).

32. Position the paper pull over the front flap

with punch holes of each aligned,

and with the bottom tab positioned below,

flat against flap. Secure in place with

adhesive on the bottom tab and buildup

edges of the bracket. Also attach mini brads

through punch holes.

-OR-

. . . select the metal hardware Label Pull

from Jim Holtz shown here . . .

. . . to position and attach with appropriate adhesive

in position, then add decorative mini brads at punch holes.

33. Position the lid assembly and attach the

back flap to the back wall using appropriately

strong adhesive.

(Hot glue or Fabri-Tack recommended.)

34. Insert the optional label shape into the

label pull.

35. Prepare and insert the optional bobbins tote

into the space created by Wall F at box front.

NOTE this will be a snug fit.

36. Close the box in the usual fashion,

and note that the front flap will "snap to"

as the hidden washers and magnets attract.

Here are views of the completed notions box.

Oh how fun! I love that this is beautiful as well as functional!

ReplyDeleteI am in love!

ReplyDeleteWOW - WOW ! WHAT A LOT OF WORK AND SO FUNCTIONAL AND BEAUTIFUL !

ReplyDeleteTHANK YOU FOR SHARING! ! !