Larger than life replica vintage fishing reel

fits together

as multi-segment edge lid over base, with whole discs

on front

and back. On box front, reel layers include

center stubby stem that holds

built-up handle and

small cylinder knob (cut 5/16” dowel lengths or

use

slot-together X struts to fit inside tube for strength).

A short optional bracket style “stand” is included

(omit the stand to create a simple round-ish box).

On back, finger holes assist opening of snug fit box.

Add touch of realism if desired by wrapping

coordinated twine around hull.

Custom sized to fit the Fishing Hat 3D Easel Card inside.

Box chamber measures approx. 5” tall x 5.625” wide

x 1.875” deep when closed (with legs, a little taller).

ASSEMBLY: 1. Identify and cut the shapes:

A & B box front and back disc

C front accent disc D front accent rim ring

E front dimensional ring: base whole circle,

show-thru accent and front overlay with cut outs

F dimensional ring rim

G box lid with lower & upper boxing strips

H box base with lower & upper boxing strips

I handle top layer J handle middle layers build up (6-7)

K handle bottom layer

L handle knob (upper) M handle post (lower)

N stand upper and build up layers (2-3)

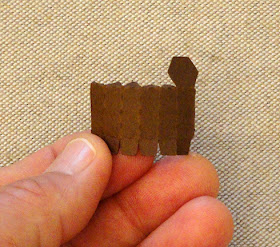

O stand accent shape overlay

P stand next to bottom layer (with tab offset opening)

Q stand bottom layer (whole)

S stand attachment panel

T alternate slot-together post reinforcements

(specific pairs for stand posts, handle post & knob)

U-W handle rivet/screw accent shapes:

U base show-thru contrast to screw head semi circles

V rivet rim (match to handle paper)

W screw head semi circles

2. Prepare the handle build up layers so they can

be allowed to dry while other assembly takes place.

Position and attach the interior handle layers in a stack,

taking care to align all outer cut edges as precisely

as possible.

Press the stack under a heavy, flat object such as

a book, or this fabric-covered repurposed flat weight,

to avoid warping or curling when liquid adhesive is used.

(This may take one hours.)

3. Identify the base boxing strips which include tiny

punch holes in the end tabs.

(NOTE that finger/thumb grab holes or push through tabs

have been added to the BASE panel and BACK DISC

in the final cut file.)

4. Prepare the boxing strips by bending back the segments

of each on perforation lines, also bend back along

perf lines of all side and end tabs.

5. Position the BASE panel bottom straight edge

along the center bottom, overlapping the flange to

the perforation line, adjust then glue in place.

6. Work up one side, bending to align the next segment

straight edge with the corresponding tab perforation

line, and gluing in place. Then . . .

. . . continue to complete

all segment edges and tabs on one side.

NOTE that the assembly can be placed face side down

on a flat surface to allow fingertip pressure to be

applied along all the tabs for firm attachment.

7. Repeat for the segments on the other half.

8. Position the upper boxing strip so that the straight

end overlaps the end tab/flange of the lower strip,

adjust and glue the seam.

9. Repeat for the opposite side seam.

10. Apply adhesive to all the tabs along the upper

boxing strip, then work quickly to align the center top

edge, then adjust and attach tabs along each side

until all are attached.

11. Repeat steps 5-10 for the box LID.

12. Position and attach the front whole disc over

the LID box assembly, centering for offset overlap

all around except at lower long segment.

13. Repeat for the back whole disc, taking care

to line up the thumb/finger holes with push through tabs.

14. Prepare the dimensional disc rim strip by adding

a little curl to it using a rod or dowel tool.

15. Bend the tiny tabs back so that they will be inward.

16. Form the strip into a ring, face side outward,

to overlap the straight end to the perf guide marks,

and glue the seam.

17. With tabs downward, apply glue to the backside

of tabs all around, then . . .

. . . slip the base disc into the ring and press into place

to fit snugly at the bend line between strip and tabs.

Place the assembly on flat surface to press fingertips

or tool - as shown in following photo - to assist the tabs

to attach (shown after the contrast accent shape

is positioned and attached in place).

18. If needed, the accent disc can be identified

as NOT being the base disc by the tiny notch cut out.

19. Position and attach the top accent cutouts disc

inside the rim ring and attach in the same manner.

20. Position and attach the front disc and rim.

21. Position the dimensional disc assembly over

the front of the accent disc, align the center hexagon

openings as precisely as possible, then attach in place.

22. Prepare the post strips by bending back along

the vertical panel perforations and end tab,

and also bend forward the top and bottom tabs.

Prepare the knob strip in similar manner,

bending the top wedge tabs back and top hex cap back.

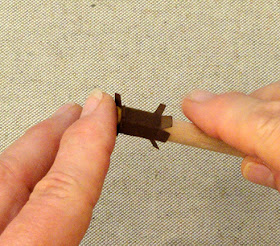

23. Form the strips into a tube to overlap the sidestraight edge over the opposite tab to perforation line

(knob strip shown here).

NOTE that this may be easier if working with a 5/16"

wood dowel as a 'form' to wrap post or knob strip around.

24. For knob, move the post tube to one end of dowel,

then bend the wedge tabs inward, and . . .

. . . cap down into place and glue all securely.

For other post strips, the end tabs remain simply bent.

25. If using wood dowel 'nubs' as knob or post insert

for reinforcement or strength, bend bottom tabs (knob)

back out of the way and mark with fine pencil or other

a line as cut off guide. Then cut the dowel segment

and sand rough ends as needed.

26. For the posts, move the inserted dowel cut end

to align at the tab perforations at one end, then

bend opposite end tabs out of the way to mark.

Then cut the dowel segments to marked size.

27. From the face side of top hand layer, insert

the knob tabs through the hex opening, then . . .

. . . bend back and glue in place on underside.28. Repeat for the bottom handle layer with

the designated and prepared post strip.

29. Insert the appropriate dowel nub into knob

tube fully and glue in place.

30. If preferred, cut and use the card stock slot-together

X reinforcements as shown, intersecting the two strips

at slots and pushing fully together so that top and

bottom edges align.

Insert X strut into the open end of knob or post

so that the 'X' arms fit into opposite pairs of bend angles.

Slide fully inside.

31. Position and attach the handle top layer onto

the top of the built-up assembly; clamp in place if

necessary to ensure complete attachment.

32. Repeat for the bottom face shape and post,

attaching to the bottom of the build up.

33. Insert and glue the dowel post nub or X struts.

34. Insert the post end tabs through the center hex opening

of the front disc assembly, then . . .

. . . on the underside, bend back the tabs and

glue in place.

To aid the handle in "drying" in the appropriate

positioning, with parallel GAP between handle

underside and disc, consider propping it up with

something of the appropriate thickness.

35. Position and attach the front disc/handle assembly

onto the LID whole disc panel, and glue in place.

36. Assemble the handle pivot faux screw head

assembly by layering the ring on top of the base

with outer edges aligned, then position and attach

the screw head semi circles inside the ring.

37. Position and attach at center end of handle

as shown.

NOTE: the following few steps are for assembly

of the "optional" stand, which can be omitted if preferred.

38. Position and attach the top 2-3 oval panels for thickness

build up, taking care to align the hexagon opening cut edges

and outer edges as precisely as possible.

39. Position and attach the bottom interior panel

(with offset larger hex openings) to bottom of

build up panel.

40. Position and attach the accent shape on topof the stack, aligning hex opening edges carefully.

Press under a weight until dry.

41. Insert post end tabs through hex opening, then . . .

. . . bend tabs back within recess and glue in place.

Repeat for the other post.

42. Position and attach the whole bottom panel

to enclose the post ends inside.

43. Insert and glue dowel nubs or X struts inside posts.

44. Position post top tabs in "skinniest" formation, then . . .

. . . insert through the face side openings of

attachment panel, and . . .

. . . bend tabs outward and glue in place.

45. Position and attach the attachment panel

with stand along the bottom face of LID.

It is recommended to use a sturdy, quick-grab

adhesive such as Fabri-tack.

46. To close the box, insert the BASE into bottom

of LID (NOTE that this is a snug fit.).

Here is the completed reel box.

For extra authenticity, consider wrapping 14-16 yards

of twine around the boxing strips of the closed box,

hiding and securing ends as neatly as possible on

bottom panel, and weaving around stand posts

as needed as wrapping fills in.

Open box to insert the companion designFishing Hat Easel Card inside.

this is awesome. thank you for the very clear instructions.

ReplyDelete