Replica lantern-style vessel has fold-over rim

with punch holes to attach a rustic wire "handle".

Front panel can be

switched out

for any one of three face variations included in the file.

Use

contrast back panel to show through feature openings,

or leave off panel and

place an electric candle

inside to shine through.

Measures approx. 7.125"

tall x 4" wide x 4" deep.

ASSEMBLY: 1. Identify and cut the shapes:

A hull front B hull back

C front face panel (one of 3 options)

D contrast back panel for face panel

E bottom panel (with cutout for finger access)

F bottom panel cover

G bottom "foot" rings build up (4; optional)

H top panel (with rim slots)

I neck strips (2) J handle hole reinforcements (8)

into two stacks of four shapes each.

Place under a flat heavy weight until dry.

angled seam along top and bottom edges of each

hull shape, pinching/creasing all the way into corners.

the straight edge and opposite flange together,

overlapping straight edge to flange perforation line,

adjust top to bottom and join seam.

and join the second side seam.

bend the second flange tab inward into position

while at the same time overlapping the back edge

over the previously-positioned rim to form

a mitered narrow "seam".

13. Repeat for all inner flange tabs. When the final

flange tab is overlapped and positioned,

the lead edge will need to be tucked under

the first flange tab rim to continue the sequence.

and glue in place.

NOTE that it may be helpful to place the assembly

on a flat work surface to apply pressure to the area

where the tabs are joining underneath.

15. Bend top panel edge tabs inward, then

insert the assembly into the top opening of hull

to align hull edges with corresponding

tab perforation lines/edges of neck assembly,

adjust, and glue in place all around.

Use the neck opening and front opening

as finger access for assembly.

manner to top panel assembly in Step 15.

18. Position the foot ring assembly, centered,

on the outer surface of the bottom panel cover,

and glue in place.

Cover with a heavy weight while drying.

through the reinforced neck punch holes

and otherwise embellish as desired.

A hull front B hull back

C front face panel (one of 3 options)

D contrast back panel for face panel

E bottom panel (with cutout for finger access)

F bottom panel cover

G bottom "foot" rings build up (4; optional)

H top panel (with rim slots)

I neck strips (2) J handle hole reinforcements (8)

2. Prepare the optional "foot" rings build up

by layering all shapes carefully with all edges lined up

as precisely as possible. To avoid warping

and distortion, place the ring assembly under

a flat, heavy weight for several hours until thoroughly dry.

3. Layer and attach the handle hole reinforcement circlesinto two stacks of four shapes each.

Place under a flat heavy weight until dry.

4. Prepare the front and back hull shapes by

bending back on all panel, top, tabs and side flange

perforation lines.

Take care to bend back the wedge tabs at eachangled seam along top and bottom edges of each

hull shape, pinching/creasing all the way into corners.

5. Position, overlap and attach the first side seam

to join the two hull panels, taking care that each end

of seams align properly.

6. Form the hull unit into a tube to bringthe straight edge and opposite flange together,

overlapping straight edge to flange perforation line,

adjust top to bottom and join seam.

7. Bend the top panels inward slightly to

align edge over wedge tab to perf line and join

seams across top.

Repeat across bottom of hull.

9. Prepare each of the neck strip shapes by

bending back on top two "rim" perforation lines,

side tabs back, and bend bottom tabs outward.

10. Overlap ends and join first side seam.

11. Form the neck strips into a ring to overlapand join the second side seam.

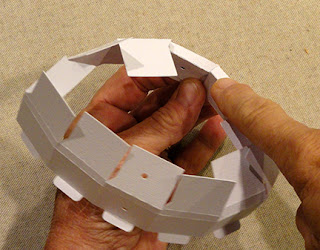

12. Form the neck "rim" by bending

the first top flange tab inward . . .

. . . until the straight end edge aligns with

the bottom edge (next to tabs), and glue edge

in place.

Working around the rim edge in clockwise direction,bend the second flange tab inward into position

while at the same time overlapping the back edge

over the previously-positioned rim to form

a mitered narrow "seam".

13. Repeat for all inner flange tabs. When the final

flange tab is overlapped and positioned,

the lead edge will need to be tucked under

the first flange tab rim to continue the sequence.

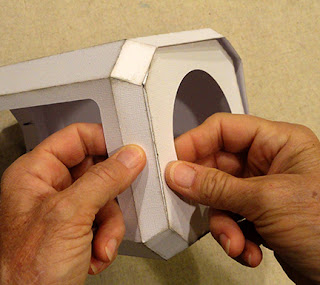

14. Prepare the top panel by bending back on

all outer edge tabs.

Position the neck assembly over the top panel

with the punch holes centered along two side edges

as shown (these edges become the "sides").

On the top panel backside, bend the tabs outwardand glue in place.

NOTE that it may be helpful to place the assembly

on a flat work surface to apply pressure to the area

where the tabs are joining underneath.

15. Bend top panel edge tabs inward, then

insert the assembly into the top opening of hull

to align hull edges with corresponding

tab perforation lines/edges of neck assembly,

adjust, and glue in place all around.

Use the neck opening and front opening

as finger access for assembly.

16. Position a reinforcement circle unit on the

inside of rim exactly over the punch hole opening,

and glue in place. Repeat for second side.

17. Prepare the bottom panel by bending back

on all perforation lines. Then . . .

. . . insert into the hull bottom opening in a similarmanner to top panel assembly in Step 15.

18. Position the foot ring assembly, centered,

on the outer surface of the bottom panel cover,

and glue in place.

Cover with a heavy weight while drying.

19. Position and attach the bottom cover,

centered, over the bottom finger access opening.

20. Position the selected face panel, centered,

over the front panel opening, and attach.

21. Apply adhesive to appropriate contrast panel

edges, then insert face side outward into the hull

through neck opening, and slot into place

behind the face panel, fitting neatly into

the recess created by hull edges attached to face panel.

22. Prepare and attach a wire or jute handlethrough the reinforced neck punch holes

and otherwise embellish as desired.

No comments:

Post a Comment