Classic pickup has truck-load of details

(shaped engine

hull with front grille and bumper, wheel fenders,

dimensional wheels with

dowel-reinforced axles,

cargo bed with accents, and more)

and is sturdy enough

for storage and re-use.

Cargo bed can hold store-bought or paper creation

Christmas evergreen to re-create a nostalgic memory

for mantle or shelf

display, centerpiece.

This project may require some dimensional

paper crafting

experience.

Measures approx. 11.75" long (including bumper)

x 6" tall

x 5.375" wide.

Pair it with "Countdown 3D Blocks for Pickup

Truck"

design and Fence 3D Cargo Bed for Truck

to help count down the days until Christmas.

Find the tutorials for the Blocks HERE, and

for the Fence sections HERE.

ASSEMBLY: 1. Identify and cut the shapes:

ENGINE HULL SECTION

A engine hull body main shape

B hull overlays (left, center, right)

C interior support

D front left & right wheel fenders with overlays

E front end build up (2) F grille

G front end base with headlamp extensions

H head lamp shapes (base red lamps 2 l & r;

chrome rim 1 l & r; lamp 1 l & r)

I front bumper and top overlay

OO truck bed main shape

P truck bed liner accent

Q left & right outer accent overlays

R tail gate (outer) accent with frame overlay

(NOT SHOWN: chrome latch handle shape)

S inside side accent overlays l & r

T interior front, tail gate accent panels (2)

U back wheel fenders with overlays l & r

V wheel front (outer) shapes (4)

W wheel back (inner) shapes (4)

X wheel interior support (4)

Y wheel front overlays (4)

Z wheel whitewalls and hubcaps (4 ea.)

AA axle posts (2)

CHASSIS SECTION

*BB chassis bottom layer

*CC chassis reinforcement top layer

(these shapes have been modified slightly)

DD chassis support boxes (2)

EE axle boxes (2)

FF running board with overlay (2)

ENGINE HULL ASSEMBLY

2. Prepare the main engine shape by bending back

on all perforation lines for hull panels, tabs,

flanges, etc.

and glue in place on outside of front panel.

Bend the top tabs one in each direction,

and glue in place.

and insert support bottom tabs (pairs) through slots,

bend tabs in opposite directions.

but leave the bottom extension un-folded.

front end accent extensions, aligning edges

that match up.

onto bumper assembly top face.

20. Insert the bumper tabs through slots from

front of grille accent shape. Bend tabs down

and glue in place.

CAB SECTION ASSEMBLY

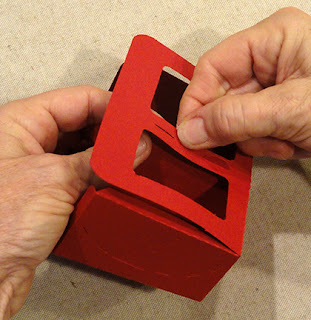

23. Prepare the cab main shape and add-on

back panel by bending back on all panel, tab

and flange perforation lines.

and roof straight edge, and complete seam.

frame accents.

Also position and attach the window rims for front

and back window openings.

the door handle shapes in the cutout recesses.

NOTE it is recommended whenever a stack of shapes

is glued together with liquid adhesive to use

a flat weight such as this fabric covered repurposed

free weight to press the stack to help avoid

warping, curling or other distortions, until the adhesive

is completely dry.

with cab top panel corners aligned with

the guide mark corners on roof underside

(roughly centered) and glue in place.

symbol cut into the center outer tab

as indicated here.

segments into position one at a time, to align each

with a corresponding straight edge segment,

and glue each in place . . .

. . . along both arch halves.

Here is the left front fender completed.

identified by a tiny triangle shape cutout in the

flange, as indicated by pointing finger.

Bed side, then . . .

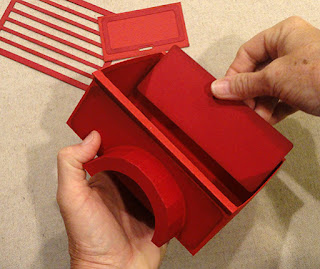

44. Position and attach the outer accent shapes.

46. Prepare the tail gate accent by positioning

and attaching the frame accent on top, with

offset margins all around as shown.

. . . and side seams.

52. Position each axle box at one end of chassis

assembly, with tabs inserted into slots, and

non-tabbed inward wall flush with support box.

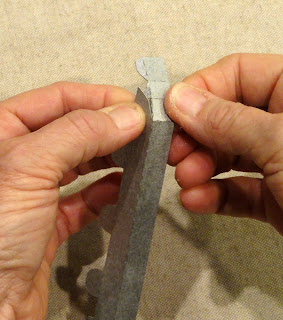

54. Prepare axle tubes by bending back on

each perforation line.

55. Form the axles, one at a time, into a tube,

using the 5/16" diameter dowel as a glue-against

surface, and overlap straight side edge over

opposite flange to perforation line, and glue

the long seam, moving finger pressure along length

until entire seam is secure, straight and smooth.

56. Measure the dowel cut length by aligning

dowel end and tube ends even,

marking opposite tube end onto dowel,

then cut to size, one for each axle.

Cut dowels to length.

center perf lines back, end tab back, top

and bottom tabs forward.

62. Form strip into a square to join end seam.

63. Position the support frame around the collar

stack, and join inner tabs to backside of wheel.

64. Prepare the four inner wheels in same fashion

as outer wheels (steps 57-58).

Also push the triangle tabs at center hex opening

back, using a tool such as the handle tip of

this spatula to make sure the tabs are bending

inward on perf lines.

into the recess at collar hex sides, then . . .

the hub cap chrome circle inside the white wall

circle shape, centered on the main (black) wheel circle.

Use a weight to help keep these layers flat.

68. When glue-up is dry, position and attach

wheel accent assembly onto the front of two wheels

that are attached to axles.

(Remaining face accents will be attached later.)

ENGINE HULL SECTION

A engine hull body main shape

B hull overlays (left, center, right)

C interior support

D front left & right wheel fenders with overlays

E front end build up (2) F grille

G front end base with headlamp extensions

H head lamp shapes (base red lamps 2 l & r;

chrome rim 1 l & r; lamp 1 l & r)

I front bumper and top overlay

CAB SECTION

J cab main section

K cab back panel add-on with window rim

L door overlay l & r with window rims

(NOT SHOWN: chrome door handle shapes)

M interior opening cover

N roof & rim base shape (note this shape

was modified after model was built)

O roof top build up layers (3)

P wheel interior post collars (4 sets of 4 ea)

TRUCK BED SECTIONOO truck bed main shape

P truck bed liner accent

Q left & right outer accent overlays

R tail gate (outer) accent with frame overlay

(NOT SHOWN: chrome latch handle shape)

S inside side accent overlays l & r

T interior front, tail gate accent panels (2)

U back wheel fenders with overlays l & r

V wheel front (outer) shapes (4)

W wheel back (inner) shapes (4)

X wheel interior support (4)

Y wheel front overlays (4)

Z wheel whitewalls and hubcaps (4 ea.)

AA axle posts (2)

*BB chassis bottom layer

*CC chassis reinforcement top layer

(these shapes have been modified slightly)

DD chassis support boxes (2)

EE axle boxes (2)

FF running board with overlay (2)

ENGINE HULL ASSEMBLY

2. Prepare the main engine shape by bending back

on all perforation lines for hull panels, tabs,

flanges, etc.

3. Bend the rounded-top front panel back and

adjust the near-center hull segment so that

the wedge tab perf line aligns at corresponding

edge segment of front panel, and glue in place.

4. Continue along the same front panel edge to adjust

and align the next hull segment tab to hull, etc.

Repeat until three rounded edge tabs are attached

to front edge, as well as the longer side edge

aligned and attached to front panel side edge.

5. Repeat for the opposite half of the hull

and front edge tab-to-edge attachment sequence.

NOTE: the hull bottom panel remains unattached

at the point in the assembly

6. Prepare the interior hull support by bending

the shape in half, allowing the embedded tabs

to extend away as shown.

7. Fold the support shape in half, and glue together

the panel sides leaving all tabs unattached . . .

. . . so the pairs that align can be independently

bent away from each other, as is shown here

with the bottom pair of tabs.

NOTE: tabs will be folded together to be inserted

into the appropriate slots during next steps.

8. Orient the support shape to match the angled

upper edge with the hull slanted top, then

insert into the hull cavity . . .

. . . to insert the top (single) tabs into the slots

on top, and the front (paired) tabs into

the hull front panel slots.

Bend the front tabs in opposite directionsand glue in place on outside of front panel.

Bend the top tabs one in each direction,

and glue in place.

9. Identify the bottom panel inward corners and

the nearly alignment dash cuts:

this extension beyond dash cuts is NOT a flange

that should be bent, but an extending panel

that will eventually fit under the cab assembly

and be glued in place.

DO NOT bend it back.

10. Bend the hull bottom panel back into positionand insert support bottom tabs (pairs) through slots,

bend tabs in opposite directions.

At the same time, position, align and attach

the hull side bottom flanges (which have been

bent inward), taking care that the panel is

forced toward the back as completely as possible,

with the extension dashes visibly beyond side walls.

11. Bend the side back flanges inward,but leave the bottom extension un-folded.

12. Prepare the top hull accents by bending back

slightly on the perforations, then position and

attach over the corresponding angle perforations

on hull, with offset at edges as shown.

13. Identify the light accent shapes:

top: lamp circles

middle: chrome "rings"

bottom: headlamp base pairs for build up stack

14. Position lamp circles centered on chrome circles.

Stack and attach base pairs.

Position, offset, and attach lamp/chrome units

slightly off-centered toward the rounded end

of base stack shape (see next frame, top left).

15. Position and attach headlamp units ontofront end accent extensions, aligning edges

that match up.

16. Prepare the dimensional bumper by bending

back on all perforation lines for narrow panels, tabs.

17. Bend the front face panel down, bend the side

extension boxing into position so that tabs slide

under the top panel, and tab perf lines align at

top angle edges. Complete for both ends.

18. Also bend the back end boxing panel around

the corner and join the tab under top panel

in same manner.

19. Position and attach the top accent shapeonto bumper assembly top face.

20. Insert the bumper tabs through slots from

front of grille accent shape. Bend tabs down

and glue in place.

21. Layer the frame-only grille under-stack shapes

behind the grille/bumper assembly with edges aligned,

and glue in place. (This provides strength and also

allows a little separation and space behind grille.)

22. Position the grille/bumper unit onto front of

front end base with corresponding edges aligned,

and attach layers together.

(Set aside until the rest of truck assembly is completed.)

23. Prepare the cab main shape and add-on

back panel by bending back on all panel, tab

and flange perforation lines.

24. Bend side panels back, and bend front upper panel

back to align the upper front edge with side

wedge flange, and glue seam.

25. Bend the roof panel back to align flange perf lineand roof straight edge, and complete seam.

26. Bend the bottom panel into position

and complete seam.

27. Repeat steps 24-26 for the opposite side seams.

28. Position and attach the door panel windowframe accents.

Also position and attach the window rims for front

and back window openings.

29. Position and attach the door accent units

onto each side panel of cab assembly.

Though not shown here, position and attachthe door handle shapes in the cutout recesses.

30. Position the engine hull assembly at front of

cab and insert back tabs into cab slots, work tabs

fully through to inside, then bend downward

and glue in place on cab inside.

31. Apply adhesive (tape recommended) to inside

cab cover panel, then insert through cab back

opening, center over the openings that access

engine hull, and attach in place.

32. Bend the cab back and bottom flanges inward,

bend back panel into position to align straight edges

with flange perforation lines, and join the three seams.

33. Prepare the roof reinforcement/build up shapes

by layering and attaching, taking care to align

all cut edges as precisely as possible.

is glued together with liquid adhesive to use

a flat weight such as this fabric covered repurposed

free weight to press the stack to help avoid

warping, curling or other distortions, until the adhesive

is completely dry.

34. Prepare the roof unit by bending back on all

panel or boxing edge perforation lines, and at tabs.

NOTE changes in appearance in roof file shape

here and throughout the roof assembly steps.

35. Bend the front, sides and back boxing

sections down.

Bend the front boxing rim tabs back and under

the roof edge, bend to align tab perf lines

with roof front straight edges, and join

tabs with each segment.

36. Bend the tiny corner tabs back,

position and attach boxing wall straight ends

over corresponding tab perforation lines

to form a roof "tray".

36. Position the roof tray under the roof build up stack,

with outer edges aligned as precisely as possible,

and glue in place.

37. Position the roof assembly over top of cab,with cab top panel corners aligned with

the guide mark corners on roof underside

(roughly centered) and glue in place.

38. Prepare the fender (wheel cover) shapes left

and right, front and back pairs,

by bending back on arch segments

and inward tabs. NOTE it may be helpful

to leave the arch segment outer tabs un-bent

to assist with insertion into slots.

FRONT fenders can be identified by a tiny "+"symbol cut into the center outer tab

as indicated here.

Also identify the "back" end of the attached arch

shape (shown by pointing finger here)

which has the more acute or pointed shape.

This is important for positioning the correct fender

onto the hull assembly.

39. Bend the segment panel tabs back, segments into position one at a time, to align each

with a corresponding straight edge segment,

and glue each in place . . .

. . . along both arch halves.

Here is the left front fender completed.

40. Position the appropriate fender at the hull

panel with the arch slots, then insert each tab

carefully into corresponding slot until fender

body is flush with hull. Bend tabs downward

on hull inside and glue in place, including the

"solo" tab that is inserted into the cab interior.

NOTE: front-most tab does NOT have a slot,

but instead is bend inward and glued to hull.

CARGO BED ASSEMBLY

41. Prepare the cargo bed main shape by

bending back on main panel division perforation lines.

At front and back center edges, bend flanges back.

On side edges, bend the outer "rim"

perforation line BACK,

and the next two perforation lines FORWARD.

NOTE the front end of the Bed shape can beidentified by a tiny triangle shape cutout in the

flange, as indicated by pointing finger.

42. Form the Bed shape into a "tray" by bending

sides, front and back into position, flange tabs

bent inward. Align straight edge with flange perf line,

and join the four corner seams.

43. Locate the tiny guide mark cuts along Bed side, then . . .

. . . apply glue to underside of the rim section,

then push the rim inward to attach to outer face

of Bed wall, with bottom rim edge aligned

at guide marks.

45. Position the appropriate left or right back

fender assemblies at Bed sides, then insert

tabs through slots as previously done for

front fenders.

On bed inside, bend tabs downward and glue

in place.

Bend the back end bottom tab under and glue

in place as with front fenders.

and attaching the frame accent on top, with

offset margins all around as shown.

47. Position and attach the interior accent

"covers" or shapes to sides, front and back.

Also position and attach tail gate on outside back,

and bottom "liner" in bottom of Bed.

(Though not shown, also position and attach

the tail gate handle shape in the panel recess.)

CHASSIS PREPARATION & ASSEMBLY

48. Prepare the axle box (left) and support box

by bending back on all panel and tab perforation lines,

except, on support box, outer-most flanges

will bend forward.

49. Form the support box into a tall narrow

form with flange tabs inward, then align and glue

bottom . . .

50. Position chassis main (bottom layer) shape

face downward. Insert support box through

the cut out rectangle opening, and push through

until flange perforations align with opening edges.

Apply adhesive to attach side and end flanges

in place to chassis back side.

NOTE the chassis layers have been slightly modified

from those shown in assembly model.

51. Prepare the axle box in similar manner,

bending ends and sides back to align and join

corner seams for form a tray.

assembly, with tabs inserted into slots, and

non-tabbed inward wall flush with support box.

On underside, bend tabs outward and glue in place.

On front make sure that end tab is tucked under,

then glue in place, while also . . .

. . . applying glue between support and axle boxes

where walls touch. Apply pressure to all areas

being glued until secure.

53. Position chassis top layer over main assembly

with outer edges aligned where they match,

and glue securely in place.

(Turn assembly top-side down, and use

weights as needed to assure flat joining.)

WHEELS & AXLESeach perforation line.

55. Form the axles, one at a time, into a tube,

using the 5/16" diameter dowel as a glue-against

surface, and overlap straight side edge over

opposite flange to perforation line, and glue

the long seam, moving finger pressure along length

until entire seam is secure, straight and smooth.

dowel end and tube ends even,

marking opposite tube end onto dowel,

then cut to size, one for each axle.

Cut dowels to length.

57. Prepare the outer wheel shape by bending

back on all perforation lines.

56. Bend boxing section tabs back so they will

tuck under the "round" wheel shape . . .

. . . then bend boxing to perpendicular to align

each "round" segment straight edge with

corresponding section tab perf line, and joining

the 3 segment seams

57. As each sequence is completed,

apply glue to the end tab . . .

. . . then bend the next

sequence strip into position to join straight end

over tab perf line.

58. As final sequence seams are completed,

also tuck the end tab under the lead sequence

straight end and join that seam as others

are joined.

59. Prepare the axle collar stabilizer stacks

by layering the four duplicate shapes and gluing

together, taking special care that the inner edges

of the hexagon opening are aligned as precisely

as possible. Use weight to keep flat during drying.

60. Position one collar on the inside of each outer

wheel, making sure hex openings align.

61. Prepare the interior support strip by bendingcenter perf lines back, end tab back, top

and bottom tabs forward.

62. Form strip into a square to join end seam.

63. Position the support frame around the collar

stack, and join inner tabs to backside of wheel.

64. Prepare the four inner wheels in same fashion

as outer wheels (steps 57-58).

Also push the triangle tabs at center hex opening

back, using a tool such as the handle tip of

this spatula to make sure the tabs are bending

inward on perf lines.

65. Apply glue to support tabs . . .

. . . and to outer side faces of inner wheel. . .

. . . and to face of triangle tabs at center opening,

then . . .

. . . fit the inner wheel inside the outer wheel,

using a blade tool as needed (this is a snug fit)

and slide the wheel components together fully.

Apply pressure to all areas where glue was applied.

but move quickly onto the next step.

66. Insert one end of axle assembly into inner wheel

opening and push in fully . . .

. . . taking care that end seats into the collar opening.

Back the dowel out slightly to apply liquid glueinto the recess at collar hex sides, then . . .

. . . reinsert fully until dowel end is flush with wheel front.

67. Prepare the wheel accent faces by centeringthe hub cap chrome circle inside the white wall

circle shape, centered on the main (black) wheel circle.

Use a weight to help keep these layers flat.

68. When glue-up is dry, position and attach

wheel accent assembly onto the front of two wheels

that are attached to axles.

(Remaining face accents will be attached later.)

69. Attach the wheel/axle assembly to chassis

by inserting axle end through axle box hex opening

(try to find the orientation of wheel that will put

a straight edge as "flat" for top and bottom positions) . . .

. . . and through box to exit opposite hex opening.

70. Follow the process in step 66 to insert and

attach each axle to second wheel, front and back.

FINAL ASSEMBLY

71. Position the front end/cab assembly over the chassis

with edges aligned with top chassis layer edges,

and centered, and attach in place.

NOTE it may be helpful to use a quick grab glue

such as Fabri-Tack, along with folio clips, clothespins,

etc. to help these layers adhere properly.

72. Position the cargo bed assembly behind

the front assembly attached to the chassis assembly,

center, then glue bottom and front panel in position.

Follow the "NOTE" advice in previous step.

73. Prepare the running board main shapes

by bending back on the middle perforation line.

74. Position and attach the rim overlay shape

at corresponding (top) rim portion of running board.

75. Position the running board along side of truck

with bottom angled flange sliding under the chassis,

with rim extending upward and perpendicular,

with ends overlapping the fenders.

Glue in place where surfaces overlap (under chassis,

on fenders).

76. Bend the back fender connector tabs

forward at center perf line, then position as shown

at the fender edge and onto the chassis surface

next to it. (This shape will help stabilize and join

fender to chassis.)

77. Position and attach the front grille/bumper

assembly.

Here are more views of the completed truck.

I've spent the last 1 1/2 day in quarentine buliding this truck! It turned out great! Many parts so I got some training of my brain though…

ReplyDeleteThanks for a great build!

Hi. could you tell me what size did u cut it out in the silhouette. I'm lost on how to print all parts at the correct sizes. I'm new with this projects.

DeleteThank You if you could reply or send me an email at

yolilove77@gmail.com

When using the svg files that are purchased and downloaded from the Silhouette America online store for use with their Cameo system, the shapes will open at their correct sizes.

DeleteWhere can the template for the 3D truck be purchased...Thanks

ReplyDeleteThe svg cut files are available for Silhouette America's Cameo system through Silhouette America's online store.

DeletePlease, please can someone help me? I recently purchased this file from Silhouette Design Store. I purchased the SVG version as I have a Cricut machine. When the file is imported into Design Space, the entire grouped image only measures 11.944 (W) x 16.523 which is no way big enough to produce the stated finished measurements.

ReplyDeleteCan someone please offer guidance as to the correct size these images should be?

Thank you

If you are using Silhouette's software, they should import or download at the accurate size. If you are using Cricut software and machines, this often has been a problem, but you will need to get advice about this from Silhouette America, if that is where you are purchasing the file. We cannot offer any support for the difficulty of importing our designs to Cricut or other systems. So sorry.

DeleteWhere can i get the truck pattern or template please

ReplyDeleteThe cut file svg is available for purchase for the Silhouette Cameo system through Silhouette America's online store.

ReplyDeleteI have a Cricut Maker and have the same problem. How do I resize this to make it work on design space?

ReplyDeleteI am afraid I can offer you no help with using our files purchased through Silhouette America on your Cricut Design Space machine. I suggest contacting Silhouette America, who I believe are still claiming that when you purchase the svg file versions, you will be able to use them with DS. Our experience with the unreal amount of customer service needed by Cricut users to use svg files, or other formats with their machines is what drove us out of business on our own. We kept working and finding work arounds, then Cricut would change things so our designs would not work. Not worth it for us.

ReplyDeleteI have this file and use Silhouette studio. When I open the file the entire file that is grouped together is 33.857 wide and 46.836 high. I do not use design space so i have no idea how files open/import but I hope this helps those with size issues in Design Space.

ReplyDeleteCan i cut this on my Cricut Maker

ReplyDeleteIf you have purchased the cut file from Silhouette America, they claim that you can cut the svg files across many if not all different kinds of machines. As you may have read in previous comments for this design or others, we have had bad luck with Cricut's software not using our svg files in the easy way that the Silhouette America cutting machines do. I cannot offer the service support you may need, but Silhouette may be able to.

Delete