Customize this tall, light up cottage to be

spooky, wintry,

spring-like or patriotic, with lots of scope in

a myriad of

details and style points. Hull

two joined shapes which include roof base.

Attach house to the

short platform base, or use

the optional bottom insert to make it free-standing.

Dimensional details include thickened attached roof and

two side gables, all with

layered ‘shake’ shingles.

A separate chimney structure with recessed top has

contrast brick mortar overlays. House front and side panels

have imitation

‘coins’ corner stone look, with door and

window cutouts and grid.

Opaque liners behind window and

door openings allow 1.5” diam. base LED

tea light candles inside to shine through.

Access candles through back panel trapdoors.

Make it spooky by adding on separate cut file designs

of Ghost Shapes Trio Layered, or

Tree Spooky Layered Tall.

House measures approx. 12.25” tall

x 3.75” wide x 4.5” deep.

Platform measures approx. 5.75” x 6.5”x .375”.

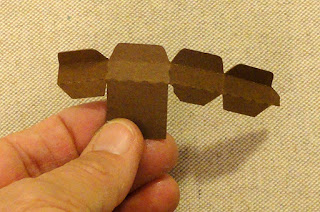

ASSEMBLY: 1. Identify and cut the shapes:

A main hull front/side B main hull back/side

C front overlay D & H side overlays

E back overlay

F & G overlay excess shapes with tab trap doors

I - L window grids with opaque window/door liners

M window shutters with contrast underlays (4 ea.)

N gable structure (2)

O roof base P roof build up panels (2 sets of 4 pcs)

Q roof shake strips (2 sets)

NOT SHOWN: roof ridge strip

R gable roof base (2) with shakes (2 sets

of 3 pieces left, 3 pieces right)

S hull interior roof triangle support

T chimney U brick mortar overlays (2 ea of 2)

V chimney top recess W chimney cap stones (4)

X platform upper (lid) Y platform base

Z collar strip (2; modified in final cut file)

AA interior tealight platform and reinforcement

BB tealight cup (2)

CC side fence with build up (2 sets)

DD front/back fence sections with build up

(2 sets left & right)

a. Just a note about cutting the roof "shake" strips

for the main hull and also the two gables:

these can all fit onto one 12x12 sheet of card stock

if that is your desired coloration.

for the main hull and also the two gables:

these can all fit onto one 12x12 sheet of card stock

if that is your desired coloration.

2. Prepare for later assembly by first identifying

those shapes that will include layering for build up

thickness and strength, and assembling those

(fence long sections, roof build up panels, interior platform;

NOTE for short fence sections, first trim away the duplicate,

build-up layers of the tabs, leaving only the face paper tabs).

NOTE for short fence sections, first trim away the duplicate,

build-up layers of the tabs, leaving only the face paper tabs).

A. here the long fence section is layered with face shape

and two bottom layers, glued together with accurate

alignment, then . . .

. . . placed under a flat weight such as this re-purposed

fabric covered free weight and allowed to dry

for a few hours. This will help minimize warping or curling

when using liquid adhesive that will need to dry.

when using liquid adhesive that will need to dry.

B. Roof build up sides are also layered, with the top layer

being the shape that includes the top edge alignment

dash cuts indicated here.

Layer roof sections, taking care to align all cut edges

as precisely as possible, then place under a weight

until completely dry.

C. Here, the interior platform shape is first prepared

by bending back the edge flanges, then . . .

. . . the reinforcement layer is positioned and

glued in place, within the flange perforation lines.

Weight this shape and allow to dry.

4. Prepare the main hull shapes bending back

on all section and tab perforation lines.

Then position and attachthe overlay shapes with

approx. .1" edge offset, with BOTTOM EDGES aligned.

This frame shows the front/side hull;

the back/side hull is similar, except the trap door

panel attachment tabs will need to be inserted

under the overlay, so wait to attach the BACK

shape 'til those are in place, OR leave that portion

UNGLUED until the flange tabs can be placed.

5. Prepare the back trap door covers by retaining

the cutouts from the back/side overlays.

Prepare the trap doors by bending forward at the long

side tabs (for attaching) and the short finger tabs.

Position overlay shapes on top of the door shapes

and glue in place with edges matching where they can.

the cutouts from the back/side overlays.

Prepare the trap doors by bending forward at the long

side tabs (for attaching) and the short finger tabs.

Position overlay shapes on top of the door shapes

and glue in place with edges matching where they can.

6. Position the door assemblies into their openings . . .

. . . and slide the tab of the base under the overlay edge,

then attach tab to hull, and overlay to tab.

Repeat for the second door.

7. Position and attach the opaque (vellum) liners

behind the round front window and door

and the side windows.

8. On the front of the hulls, position and attach

each of the corresponding window or door grids,

lining up the inside edge of the grills with window

opening edges.

9. Position and attach each contrast liner shape

behind each shutter shape.

(This image of shutter is shown upside-down.)

10. Position and attach each shutter unit at

the side of each rectangular window, overlapping

the grid slightly, and entered top to bottom.

11. Align the two hull units side by side, overlap

the straight edge over the adjacent flange tag to

perforation line, make sure bottom edges match,

and glue this first hull seam.

12. Form the hull into a tube to align and complete

the side seam #2 in the same manner.

13. Bend the attached roof base portions back,

with the flanges bent back as shown, to align

the perforation edge with the roof angle edge,

adjust and glue the seam.

Repeat for the opposite seam on the same side.

14. Prepare the roof ridge triangle support by bending

back on all perforation lines.

NOTE that the panel with the circle hole is the BOTTOM.

15. Form the strip into a triangle, with the flange

tucked under the side panel, align edge to perf line,

and glue in place.

NOTE it may be helpful as the seam is glued

to insert something as a "press against" rigid form,

such as this skewer, or a Popsicle stick.

16. Position the triangle form inside the roof,

next to the roof side that is attached to angle,

center, and align the top straight edge of roof

with the top angle perforation line, and glue in place.

17. If you plan to have your house light up,

you will need to obtain two of these style LED

battery-powered tea lights. The 1.5" base will fit

in the candle cups included in this design file.

IF YOU ARE NOT USING TEA LIGHTS,

you can skip forward to step ___.

18. Prepare the two candle cup shaped by

bending back on all perforation lines as shown,

except bend the "top" set of tabs in this shot forward.

19. Bend the base octagon shape down into

the interior of the cup form, then . . .

. . . form the cup into a tube, to bring the straight side edge

to overlap the tab perf marks, opposite, and join.

20. Bend the bottom tabs inward, then push

the octagon base down into position . . .

. . . and glue in place to tabs. Assist the attachment

process by pressing from the inside with fingertip.

Complete two cups.

21. Position one cup centered on the interior platform

and glue in place securely.

(NOTE that the center punch holes of cup and panel

will line up with centered.) Set aside the second cup

for positioning and attaching on the bottom platform,

in step 52.

Later, the LED tea light will be placed in the cup as shown.

22. Bend the side flanges down, then insert the platform

through the open room into the interior space . . .

. . . and fit it down into the level just below the circle

window, as shown, making sure that it is level

all around. Glue flanges in place to the walls.

23. Bend the second roof base into position

to align the angled edges and top edges

with corresponding flanges or triangle support,

and glue all in place.

24. Prepare the gable shapes by bending back on

all perforation lines, except edge flanges which

are bent forward. Bend the "top" edge flange back

(where fingertips are in this image).

25. Position the opaque panel behind the gable

opening, and glue in place.

26. Position the window grid trim over the front

of the window opening, align inner edge with

window opening, and glue in place.

27. Bend the gable into its form to bring the top

straight edge and flange perf lines together,

and join the top ridge seam.

28. Position and glue the front angled edges

to the front flange tabs, aligning straight edges

with flange perf lines.

Complete two gable units.

29. Prepare and attach the main roof "shake" rows:

a. position the bottom row over the roof build up

with the bottom corners and side edges aligned,

and glue in place.

Also align the bottom of the gable opening as shown.

b. position the second strip with top straight edges

aligned at the dash guide marks on the roof top layer,

and also with the gable "window" cut out edges aligned,

and glue in place.

c. position each of the third row side portions in

similar manner, aligning top edges at guide marks,

with inner edges aligned with gable window edges.

d. position and attach the fourth row in similar manner.

e. position and attach fifth row as with previous rows.

f. position and attach final top row with top edges

and corners aligned.

Complete two roof/shake units.

30. Position the completed build up roof/shakes unit

on one half of the connected roof base, aligning

side and bottom edges, and taking care that

gable openings align as exactly as possible.

31. Repeat for the second roof/shakes unit on

the opposite side of the roof base.

32. Position the first gable unit so that it will

fit from the backside of the roof . . .

. . . and be pushed through the opening, with

the edges flanges perforation lines seating snugly

at the opening edges.

Glue the flanges each to the roof backside.

Complete the attachment of second gable unit.

33. NOTE that the back portion of the roof assembly

does NOT have a few shake division cuts.

This is the area where the chimney will be attached

and the shake details would be hidden.

Position the roof assembly over the hull roof,

with the "blank" shakes portion toward the BACK

of the house (where trap door openings are).

Center it from front to back so that the same amount

of overhang is at the front and back of the hull roof,

and glue in place.

34. Prepare the roof ridge strip by bending

back on the center perforation line.

Position it across the top of the roof assembly,

center front to back (end will align with roof)

and glue securely in place.

35. Prepare the roof units for the gables in similar

manner to the main hull roof shakes.

Bend the roof base back at the middle perforation.

a. position the bottom shake even with the lower

edge of the roof line.

b. position the middle shake with the top edge

at the perforation line.

c. position the top shake even with the perforation

line and with the middle shake top edge.

d. repeat for the opposite side.

Here is the completed gable roof.

Complete two units.

36. Position and attach a gable roof unit over

the gable structure, with ridge angles aligned,

and with the angled edge as snugly fit into

the main roof as possible.

Repeat for both gables.

37. Prepare the chimney structure by bending back

on all section lines, and all tabs or flanges.

38. Position and attach each of the brick "mortar"

overlay shapes within the matched shape section,

with bottom straight edges aligned, and sides

with the tiniest of offsets. NOTE that there will be

a space at the top for the cap stone accent shapes.

39. Position and attach the capstone shapes

above the mortar accent shapes, at the perf lines.

40. Form the chimney into a tube to align and

complete the side seam.

41. Bend the top tabs inward, bend the square top

down into position to align edges with the tab

perforation lines, and glue in place.

42. Prepare the top recess "tray" shape by bending

the top tabs forward, other tabs and section lines

back.

43. Bend the square bottom panel forward down

below the bottom tabs, then . . .

. . . form the shape into a tube to complete

the side seam.

44. Bend the bottom flanges inward, push

the bottom square back to perpendicular,

and glue in place to tabs.

45. Insert the tray tabs end first into the bottom

opening of the chimney and through the tube until

the recess square fits under the square opening

at the top. Adjust, then secure in place as tabs

attach around the square opening.

46. Bend all the bottom tabs inward, apply glue,

then position on the back top of the roof ridge,

approx. 1/2" in from back of roof

(even with the back wall of the hull),

and hold firmly in place until secure.

NOTE: quick dry glue such as Fabri-tack

is a good choice here.

47. Prepare the upper platform shape by bending

the side walls down, end tabs inward,

opening tabs downward.

Prepare the bottom platform in similar manner,

bending walls up, corner tabs back.

Join the corner seams of each to form shallow trays.

49. Prepare the collar shape that will help support

the platform, and also provide a glue-to surface

for the bottom of the hull.

NOTE: the collar shapes were re-designed after

the prototype was constructed to have long

flange tabs on the bottom to attach to the bottom

platform, and also an indent that is the FRONT.

Bend back at the center and tab perforation lines.

Join end to end, and also . . .

. . . join the second seam to form a ring.

50. Fit the collar into the platform top shape

center opening (this will be snugly fit) . . .

. . . and push down so that when on a flat surface

the bottom of the collar (as well as the bottom of the flanges

in the opening) reach the surface.

Glue in place. It may be helpful to turn the assembly

bottoms-up to apply fingertip pressure along the flanges.

51. Insert the bottom platform up into the bottom

of the upper platform to close this shallow "box",

and glue together all around between the side walls.

52. Position and attach the LED tea light cup in

the center, on the bottom platform backside.

53. Join the hull to the platform by applying

glue to the collar outer exposed surface, then

carefully fitting the hull over the collar, orienting

so that the collar indent corresponds to front door,

and pushing down until the bottom of hull rests

on the top of the platform. Hold in place until secure.

NOTE: if using the optional bottom insert,

it should be prepared as a tray, then inserted at this point

up into the bottom of the hull, in place of the platform.

54. Bend the fence tabs back, then . . .

. . . position on the front platform at each end,

with the tabs turning the corner where they will

attach to the long side fence sections.

Bottom edges of fence sections should be even

with the platform bottom edges.

Repeat this step for the two short fence sections

at the back of the platform.

55. Position the long fence sections along the side

platform edges, with ends overlapping and joining

to the tabs, bottom edge even with platform bottom.

56. Open the trapdoors and place the lighted

tea light candles into their cups,

then close the doors.

Here is the completed house.

Use other accessories to create your own

seasonal of other holiday versions.

Make the house spooky by adding the layered

spooky tree at the back, gluing it to the

platform and fence for support.

The ghost pair can be added at the opposite side,

with the bottom "tail" pointing at the gable window,

and the "wing/arm" of the top one overlapping

and attaching at the chimney near top, as shown.

No comments:

Post a Comment