Tall front wall with snowflake window cut

outs and

back plain wall with handle cut outs have multiple layers

to stack for

thickness, joined with tabs and slots

to thickened square base and low side

walls.

your own stamped or penned

label or sentiment,

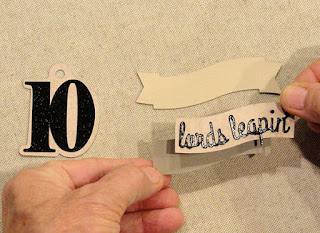

or the included “lords leapin’ word cuts to present a gift

for the Tenth Day of The Twelve Days of Christmas

themed giving.

Number 10 tag

is also included to hang

from the tote’s handle cutouts.

Designed to hold a “designer” 12 oz. soda pop bottle

(with approx. 2.5625” diameter).

May easily hold other packaged loose treats.

Tote measures approx. 10.5” tall x

3” wide x 2.75” deep

when completed and closed.

ASSEMBLY 1. Identify and cut the shapes:

A front panel with snowflake cutouts (3 to layer for thickness)

B front panel inner layer with bottom connection panels

C front panel offset accent

D back panel (3 to layer for thickness)

E back panel inner layer with bottom connection panels

F front panel offset accent

G & H side wall panels (6-7 layers to stack for thickness)

I floor panel (6-7 layers to stack for thickness)

J ten number with tag base

K front panel banner with "lords leaping" word cuts

L slot and tab layer quantity test shapes

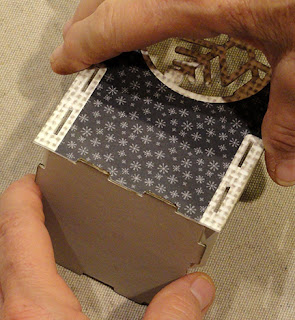

2. Determine the quantity of side panels and floor panel

so that when layered and glued together the tabs

fit snugly into the slots of front and back panels.

With tabs cut from the exact paper card stock,

stack and fit into the test slot panel as shown.

If 6 layers does not fit, eliminate one interior layer

and re-test. Whichever quantity fits as desired should

be used as the number to cut for A and D shapes in

the above list.

3. NOTE that the sample project uses

a different face paper stock than the interior layers.

Work quickly through the next layering steps.

Layer and glue together the three back (shown here)

or front layers into one slack, taking care that all

cut edges are as precisely aligned as possible,

taking particular care with the multiple slot edges,

here and throughout any other shapes that are

stacked and glued together.

4. Position and attach the offset accent back (shown here)or back panel, aligning BOTTOM notched edges as

accent is centered, with remaining edges retaining

even offset margin at side, top and handle opening edges.

5. On backside of back panel assembly stack, position

the interior panel with corresponding edges aligned

precisely, including slots, but with bottom and side bottom

connector panels kept free.

Place the stack on a flat work surface, then press flat

under an adequately-sized heavy flat object, such as

this wood plank, several thick book volumes, or

other equivalent object, and leave in place until

the liquid glue is completely dry. This may require

several hours or overnight. Pressing flat will assist

to minimize or avoid warping or curling of glued-up stacks.

6. As mentioned previously, repeat the process of

layering front cutout panels, front interior panel with

connector bottom panels, and offset accent shape

and glue together. Press under flat weight until dry.

7. Layer and assemble the two side wall stacks . . . . . . as well as the floor panel stack using

the determined quantity of shapes to fit

through the test slot.

Press stacks under flat weight until dry.8. Position and attach the number 10 welded numeral cut

onto the tag base. Press until dry

9. Position and attach the optional "lords leapin'" phrase words

(or pen stitch a recipient name, use other word cut outs, or

design stamp, etc.) onto the top banner layer.

Layer the top, middle and bottom banner layers

into a unit, aligning corresponding layers,

and glue together. Press until dry.

10. Position the banner onto the front panel overthe corresponding area at the middle of the snowflake

cutout design, center, and attach in place.

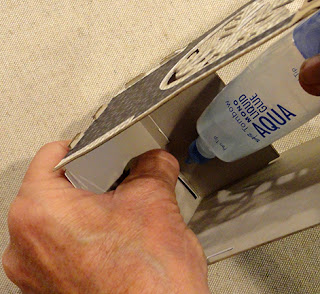

12. Retain the wall in upright position, then apply glue under

11. Apply glue to the floor panel stack thick edges

between tabs plus the side wall edges of tabs,

and also corresponding edges of tabs and thick

edge of front panel, then . . .

. . . position the bottom "floor" panel stack under

the front panel . . .

. . . with notched edges fitted together to interlock

and snack into position. Hold in place (or prop

in upright position) until glue attaches edges.

Allow to dry.

the bottom connector panel then reposition

and attach to upper surface and attach in place.

and tab edges, position and snap together

(NOTE that in the pic below, the connector panel

is folded back out of the way), then position

the back wall panel into perpendicular position

while positioning connector bottom panel onto

floor panel, and hold in place until secure,

propping if necessary.

14. Apply glue to the thick sides and bottom edges

of first wall unit, then . . .

. . . position in place at side of attached front and back

panel assembly, and . . .

into front or back panel slots.

to allow final side wall tabs to snap into slots.

Apply pressure to ensure that all tabs are seated

firmly and completely into slots, then hold or prop

into perpendicular position until glue is secure.

15. On the inside of side wall, bend the short side

15. On the inside of side wall, bend the short side

connector flange out of the way to apply glue

behind that flange, then reposition and apply

fingertip pressure to attach flange in place to backside

side wall unit by bending the side wall flange segments

up into perpendicular position and applying glue

wall unit to the other assembly, including pressing

the side connector flange segments to backside

pop bottom beverage into the interior, then . . .

. . . tie a decorative ribbon to hold handles together.

. . . tie a decorative ribbon to hold handles together.

Also add twine hanger to number and attach

No comments:

Post a Comment