Requires

12x12 cutting capacity and stock.

Large dimensional turkey features a modified

pyramid form

composed of lid and base, with a fancy tail feathers array

that

can be decorated with eleven black soda pop pull tabs.

Hat with band and

buckle are arranged assembled,

then attached to the “lid” portion of box,

along with wide eyes, dimensional

beak with wattle lobes.

Body is shaped with

contour overlays on three sides,

flanked with stylized two-part wings,

cutout breast feathers at front.

Neck feather ruffs are attached at base rim

opening.

Tail is layered, with can pull tabs attached with glue and

soft twine

(perle cotton) at lacing punch holes,

then attached at box base’s backside

bump-out.

(Shapes included to complete a tail array without pop can tabs,

or

with card stock cut faux tabs.)

4.75” thickened base square; tail array 8” wide x 5.25”

tall.

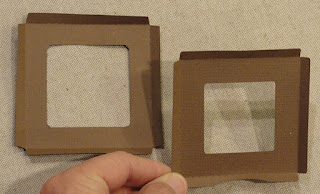

ASSEMBLY: 1. Identify and cut the shapes:

A main body BASE hull B body contour shapes

C back body bump out to hold tail array vertical

D base opening collar reinforcement

E base platform build up layers

F main LID hull G lid opening collar reinforcement

H eye assembly (lrg, middle, indiv small), wattle,

and beak

I hat crown J hat band, buckle

K hat brim with center opening tabs

L hat brim layers for thickness (2)

M wing base and overlay (1 for left set; 1 for right)

N neck feather sections (3)

O feet (1 left, 1 right)

P tail feather base (2 to layer for thickness)

Q tail feather accent with tab lacing holes

R tail feather top layer accent

Also pictured: 11 black pop can pull tabs

from Pepsi Zero cans

so they can be drying while other assembly progresses:

A) layer the hat brim sections, taking care to match up

and under a flat, heavy object such as this thick book.

Consider placing other heavy objects on top of it

to assist with the pressing, and allow the shapes

to dry for several hours or over night. Pressing

helps minimize or prevent warping or curling of

into a single stack, matching up all cut outer edges.

on all four wall panels, and on wall side flanges as shown.

4. Prepare the tail attachment "bump out" panel by

4. Prepare the tail attachment "bump out" panel by

bending back on all panel edges, bottom flange,

side walls and edge tabs, and tiny wedge tabs as shown.

5. Assemble the bump out by bending back the top

5. Assemble the bump out by bending back the top

and adjacent wall panels to bring the short side plain

edge to overlap the adjacent wedge tab to perf line,

mid-side seam. NOTE that this tiny tab and seam

may require patience to get the seam to grab.

Consider using a spatula tool blade placed flat

behind the seam to provide a press-against surface.

cut opening, then insert through the opening until

edges of opening rest at the creases of the sides

and top tabs. Glue in place. NOTE that at the bottom seam . . .

. . . the bump out has tapered to zero.

. . . the bump out has tapered to zero.

Bend the bottom flange back, apply glue, then

refold into position to attach it to the BASE's bottom panel.

8. Join the four wall seams by bending adjacent walls

8. Join the four wall seams by bending adjacent walls

into position, flange tabs bent inward, straight side

edges overlapping flange to perforation lines.

Adjust for alignment of wall edges at top of seam,

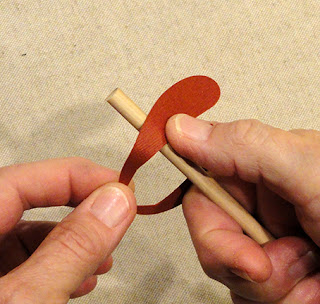

by adding some back curl from top to bottom of panel.

To do this, place the panel face down on work surface,

then hold a dowel or round shaft pencil across the panel

and flat against work surface, as panel is carefully but

firmly pulled along under the dowel and upward.

Add curl between the top and bottom flange tabs.

10. Bend the top flange forward, and the bottom flange back.

from the bump out panel, which is the back.

Position the bottom flange of the FRONT contour

panel (with the chest feather cutouts) under the front

edge of the hull, centered from side to side, push in

so that wall-to-bottom panel crease fits into the flange's

crease, and glue in place.

and align top flange tab with top cut edges matched.

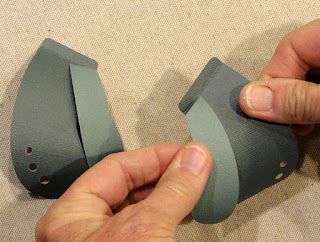

13. Repeat the process to align each of the right (shown)

13. Repeat the process to align each of the right (shown)

and left contour panels on respective hull sides.

NOTE that the back edge of the contour panel does NOT

bulge outward as the front edges do, but is straight

and in line with the hull's back panel slant.

14. Prepare the beak shape by bending back along

the center perforation line; bend the back tabs forward.

15. Prepare the feet shapes by bending the tabs back.

16. Position the feet so that they angle away from center

and slightly outward. Tuck tabs under the contour wall

shape and glue in place. Also add a dab of glue behind

the middle of foot, then bend into position and attach

to the contour wall - allow toes to be unattached and

extend slightly away from body.

17. Apply hot melt or other quick-grab glue to

the bottom of the hull and contour tabs that

wrap under base hull, then position, centered, on

the platform shape.

18. Prepare the base opening and lid opening collars

by bending the edge flange tabs forward.

19. Apply glue to the underside of base's flanges,

then insert through hull opening and into the cavity,

then carefully pull up . . .

. . . into position to align flanges top edges with

hull top edges, and glue in place.

20. Assemble the eye unit by attaching middle eye

onto large bottom "whites" eye base, then positioning

each single eye over the middle eye with highlight

oval openings aligned, as shown. Press 'til dry.

21. Prepare the wattle two-lobe shape by adding

some back curl to the long portions on each lobe

using a narrow dowel or round pencil. Then . . .

. . . finish the curl to be rolling inward so that

the inward cut edge becomes at the top of

the vertical curled edge near the bottom of each lobe.

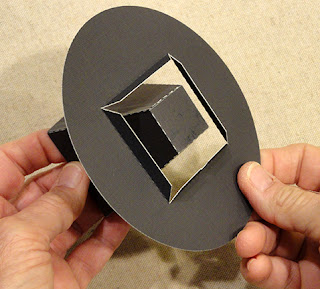

22. Prepare the LID hull shape by bending back on

all panels, side long flange tab, top "lid" square

and adjacent shaped tabs, as shown.

23. Insert the tabs from beak into the arrowhead

window on front of lid, so that tabs are along

both top angled cut edges. Then . . .

. . . on the backside of lid shape, bend the tabs back

and glue in place.

24. Position the top connector tab of the wattle

above the beak, with the underneath angled corner

edge hugging the top of the beak.

Position and attach the eyes assembly over the tab

and snugly above the beak, and glue in place.

25. Form the lid hull into a pyramid shaped tube to

bring the straight side edge in line with and overlapping

the opposite long flange, adjust for top-to-bottom

alignment, then glue the seam.

26. At the top, bend the shaped tabs inward to

perpendicular, apply adhesive to outward surface,

and bend the "lid" square down into position.

Adjust so that "lid" edges align with perforation

bend edges, then apply pressure to secure in place.

It likely will be helpful to place the lid assembly top

downward on flat work surface then insert a flat-top

tool to apply pressure all around the tabs from inside.

27. Apply adhesive to the lid opening collar edge

flanges backside, then carefully insert into the neck

edge opening (try to keep glue from spreading too

thoroughly to the inside hull edges), and . . .

. . . push inward until the collar fits into its

appropriate level. Keep the collar square parallel

to the hull's bottom cut edges, and the designed

margin of approx. .3 between flange edge and hull

edge even and uniform. This spacing away from

edges allows lid to fit onto top of body hull.

28. Prepare the hat brim shape by bending

the center flanges upward along perforations.

NOTE that the brim shape is NOT round, but

slightly oval; the half-circle notch indicates "front".

29. Prepare the hat crown shape by bending back

on all panel, "lid" side flange and top shaped tabs

as shown.

30. Form the crown into a pyramid tube, then

join side seam . . .

. . . and top in similar manner to lid hull.

31. Apply adhesive around the outer bottom edge of

crown assembly, then slip the brim assembly and . . .

. . . push into place all the way down crown so that

on the underside the crown edge aligns exactly

at brim bottom edge, as shown.

32. Apply adhesive to underside of brim joined

layers (from Step 2) then carefully slip over crown

tip and move down into position on top of

the main brim, and attach in place with outer

edges aligned as precisely as possible.

Consider pressing the newly-layered brim under

flat weights placed around edge until dry.

33. Prepare the hat band shape by bending back

on perforations that separate the four segments

and tab. Form the band into a ring to overlap

the straight side edge across opposite tab to perf line,

adjusting top to bottom, then joining seam.

33. Slip the hat band ring over the crown pyramid

and move down into position . . .

. . . resting on the brim. Move up slightly to allow

adhesive applicator tip to apply glue under the band,

then reposition and attach in place.

34. Position and attach the buckle at front of crown,

centered and with straight bottom edge even with

band bottom edge.

35. Apply glue around the bottom inside edge

of hat crown, then slip the hat over the lid head hull. . .

. . . and push down evenly into position and attach in place.

Hold in place until fully attached.

36. Close the box by placing the lid on top of

the base hull - a relatively snug fit.

NOTE the lid rims can be glued together if desired,

converting the turkey box into a decoration.

37. Prepare the wing shapes by adding back curl to

the bottom two-thirds of each main and smaller front shape.

Position the appropriate front wing shape on top of

the main wing so that top straight edge aligns

at top tab perf line, and front edge aligns with

tab's front edge, and glue together where the two

wings overlap. Repeat for the second wing assembly.

38. Position the top tab of the wing assembly

along the associated side of body hull (wings should

curve toward front as shown), with top edge of

tab fit snugly under the lid edge, with approx. 1/4" to

3/8" between back of tab and hull back edge,

and glue tab in place. Repeat for second side.

39. Prepare the neck feather units by bending

each "feather" forward at perforations.

Add back curl to each feather - as much as can be.

40. Position and attach feathers tab centered along

contour wall edge, covering wing tab.

Repeat for opposite side. Also center one neck feather

unit along base hull front below contour top perf line.

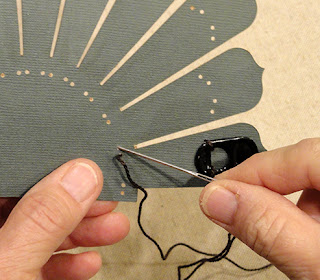

41. Tail pop can tab stitching assembly:

A) thread a 36-40 inch length of soft twine or no. 5

perle cotton onto a blunt darning needle as single ply.

B) position the first tab on the end feather as shown

with the opening oriented toward tail bottom.

Stitching punch holes should align on each side at

margin near bottom of opening.

NOTE tabs will eventually be glued in place;

you can decide if it makes sense to position

and attach prior to or after stitching.

C) on backside of first feather, use a small piece

of cello tape to anchor the tail of thread somewhat

below the first stitching hole.

D) insert needle to draw the thread through to front.

E) insert needle into the adjacent hole so that

the thread will wrap over the tab's frame and hold

it in place; draw thread all the way through to back.

F) insert needle through next "inside" hole from back

to front and draw thread fully through to front.

G) insert needle into the outward hole to wrap thread

over the second side of frame and hold tab in place;

pull thread all the way through to backside.

H) move downward along first feather to insert

needle into the closest hole near feather base,

and draw thread all the way through (here

and throughout as stitching progresses).

I) insert needle into the adjacent hole to create

a stitch that shows on front of paper shape.

These inward stitches help hide the thread

behind the paper cut shape.

J) repeat steps B-G to position and attach with stitches

the second tab.

K) repeat steps H-I to carry thread down behind

shape, then back to attach next tab.

L) continue the stitching steps to position and affix

each of the remaining tabs until all eleven are in place.

This image shows the backside of the work as

the stitching progresses.

M) if more thread is required to finish, cut and

anchor thread end in place on backside with

small pieces of cello tape, then anchor on

additional length.

N) when all can tabs are in place, trim excess . . .

. . . and anchor final end with tape.

42. Further secure the can tabs by neatly applying

a dab of quick grab multi-media adhesive behind

the solid portion of each tab's top portion.

43. Position and attach the top tail feathers accent

shape, centered, with bottom edges of each aligned.

44. Position and attach front layers assembly onto

the layered for thickness tail shape (from step 2),

centered, with bottom edges even. Press with

flat weights until all layers are secure and dry.

45. Apply quick-grab adhesive to the face of

the bump out at base hull back panel, then

position the tail assembly, centered, and with

bottom edges aligned. Hold in place until secure.

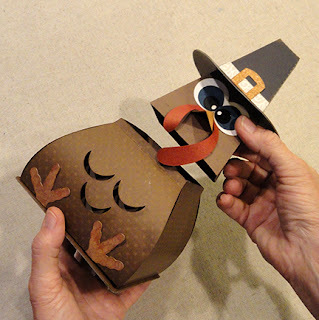

Here is the completed whimsical turkey 3D box

and decoration.

HAPPY THANKSGIVING!