Shaped

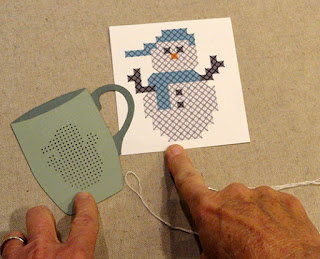

cold-weather card with the special touch

of hand-stitching features mug front

layer and

reinforcing second layer that are pre-punched to complete

a snowman

(stitching chart included in cut file).

Third layer of mug includes a cutout

that surrounds

cross-stitching as buffer.

Whipped cream swirled dollop is

layered,

then bottom flange is inserted through mug back layers slot.

Tie optional

two-layer sentiment tag through

mug handle front layers.

Optional “hugs &

hot cocoa” print and cut tag panel design

can substitute for tag as desired.

Tag measures approx. 4.125” wide x 5.6” tall

when assembled and closed.

A companion snowflake cutout flap envelope

that is sized to fit this shaped card is available also.

(Tag will need to be adjusted toward center)

ASSEMBLY: 1. Identify and cut the shapes:

A mug front layer with stitching holes

B mug second layer with stitching holes, cream slot

C mug back layer with stitching "buffer" window

D whipped cream contour front layer

E whipped cream base layer

F tag base with front print & cut rectangle

G tiny snowflake embellishments with twine ties

H card base with left side perforation for fold

I optional interior sentiment panel

Also select and assemble the stitching needles

(recommended tapestry blunt needles with large eye

size no. 24/26) and floss colors. The snowman will need:

white for snow; orange for nose; scarf & hat color;

black for eyes, buttons, arms.

2. Complete preparation and glue up for a few shapes

and press each flat under a heavy weight until dry:

A) layer the whipped cream contour front shape

onto the base shape, matching edges;

B) center and attach the "hugs & hot cocoa" print and cutpanel (or the plain label if preferred) onto

the tab base shape.

C) fold the card base in half along the perforation . . .

. . . then open to position and attach

the interior sentiment label as shown.

3. Prepare the two stitching hole shapes by cleaning outany partially attached "chad" circle cutouts from ALL holes,

using the stitching needle to push these through to

as possible. One way to accomplish this is to push

the stitching needle through several holes and

approx. 30-36" long (shorter for smaller areas),

and separating TWO of the plies.

A) Line up the ends of both plies and straighten

the plies so that they are without twists.

B) Fold the two plies to line up the four ends, then

crease the loop end to create a half-way loop.

Thread the loop through the needle's eye, then . . .

. . . pull the loop through, leaving approx. 5-6" cut ends tail.

The loop becomes the long "end", with 4 plies

together which will form cross stitches.

6. Review the following diagram to fully understand

how the cross stitches are formed uniformly

with RIGHT SLANT stitches made across the row first,

then the return half of the run completing

the LEFT SLANT stitches.

7. Refer to the Stitching Chart, either on screen,

or printed, to locate the bottom-most beard cross stitch.

This is where the first stitch will be made,

afterward working upward through the design.

8. Visualize the 'X' of the first stitch, then insert the needle

UP from backside through the top left hole of the bottom FOUR

that will create the 'X". Pull needle and thread through

leaving approx. 3-4" of loop "tail" still on backside.

9. Insert the needle into the bottom right hole . . .

. . . then pass the needle through the loop . . .

. . . and cinch the thread up firmly on the back.

This is the "tie on" step.

10. Continue the X stitch pattern in the next pair of holes . . .

. . . then continue across to complete the RIGHT SLANT stitches across the first (bottom) row of chart . . .

. . . then return back across to complete

the LEFT SLANT stitches.

11. To continue, move up to next row after each row . . .

. . . and add the LEFT slant stitches across andthen move back across to complete each X stitch

with RIGHT slant stitches.

rows. When floss length on needle gets close to being

too short to continue, pause in mid stitch when needle

is pulled through to backside, then slip the needle under

the adjacent 4-5 stitches. Pull the needle fully through, then . . .

. . . remove needle and trim the excess floss close

to the stitching it crossed under.

This is "tying off".

13. As stitching progressed up the chart, skip the stitch

spaces for the non-white Xs (neck scarf) as shown, working

LEFT slant stitches across row with thread "floating"

across skipped spaces on mug backside, then

returning back in same manner to complete RIGHT slants.

14. NOTE where the "half cross stitches" are on

the printed chart that will help shape the snowman body,

head, and scarf at some edges. One of these is indicated

in this photo, and its punch hole configuration includes

an extra tiny needle hole in the center of the usual four

holes that create the X.

Complete these special stitches by making a "half-slant"

stitch as shown on the diagram.

head, tying off and beginning new floss length as needed,

until white stitches on chart are all in place.

16. Tie on successive colors to complete scarf, hat,

arms, body buttons and coal eyes, and orange nose.

For better definition, consider tying on a two-floss length

to outline "straight" stitches around eyes and nose, etc.

. . . so that outer card stock edges match, including

curved slot edges, and that the window edges

fall just beyond the completed stitching all around.

by slipping the bottom edge of attached tab

touch and attach to backside of buffer shape.

Adjust cream shape so tab edges are parallel to

mug side edges, and so that the cream shows

appropriately at bottom above mug "rim".

NOTE that the card base offset will need to mimic

the shaped edges of cream, so compare the assembly

to the card base front corresponding edges and make

the folded card base, with .125" offset margin