Say

“thank you” to doctor, nurse, or other medical care

provider (or “get well” to loved one) with this detailed 5x7 card.

Front layers stack to create dimension

for the six

tiny windows filled with heartbeat line, tiny heart, red cross,

bottle outline with tiny pills, band-aid

(cut these double to stack for more

dimension).

Welded words “thank you” and alternative “get well”

attach across

front corner.

Hole-punched border overlay offers alternative

for adding hand

stitching.

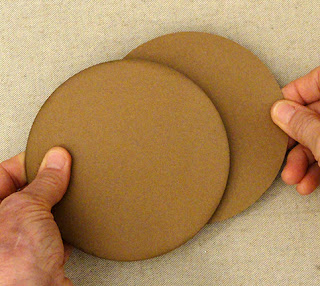

ASSEMBLY: 1. Identify and cut the shapes:

A card base with horizontal center perforation

B top layer frame (model uses punched version

for real stitching application)

C frame layer 2 - shows thru as narrow border

D 'mat' layer offset frame - matches windows layer

(NOTE: can use the 'waste' rectangle as liner for windows

under-layer instead of card base 'show-thru' if preferred:

see next photo for explanation)

E windows layer

F liner for windows layer - provides extra depth

*window content elements - cut layers for build up

G thank you (or get well) word cuts (2*)

H heart beat line (2*)

I pills (9 pieces)

J pill bottle base, outline layers (2*)

K bandaid, inset, pad

L hearts (2 layers of 2*), red cross (2*)

NOTE: the 'waste' from D frame is the perfect size

to act as 'liner' for the backside of the windows under-layer

if the card base which otherwise would show thru is NOT

a desirable color choice.

2. The sample card uses the real stitch detail on

the top frame layer. If you are NOT using that version,

you can skip forward to Step 3.

The 'thread' used for this project is DMC perle cotton

in BLACK no. 5 (obtain contrast yarn of choice)

along with tapestry-style needles in a gauge that will

fit easily through the cut stitching holes.

(Size 24 was used for this project.)

Cut a 28-20" length of 'thread', load needle, anchor

the lead end with a small piece of cello tape at

one corner on backside, then insert needle up at

corner hole, insert down at second holes, and so forth . . .

. . . to create stitches between the 'long' spacing of

holes, and skip the 'short' spaces, as shown here.

When the stitching circuit is completed, the finalhole insertion will carry the yarn through to backside

where the tail is trimmed to approx. 1/2" and held

in place with another small piece of tape.

3. Position the top frame layer over the second

frame layer (narrow border show-thru), align outer

edges precisely, and attach in place.

4. Position the windows frame build up layer

behind the main windows frame layer, line up

the window opening edges precisely, and attach.

5. Position and attach the 'mat' frame layer over top of

window frames assembly, aligning outer edges

precisely.

6. If needed, position the 'waste' rectangle panel

behind the back of windows/frame assembly,

adjust to make sure the openings are covered

with extra margin approx. equal all around, and attach.

7. Position the top frames assembly over the topof the mat/window frames assembly, align outer

edges precisely, and attach in place.

8. Fold the card base in half, inside surfaces together.

9. Position the frames assembly over the top of

card base front, adjust for even offset margin

all around, and attach in place, including the window

frame interior members.

9. Prepare the window contents elements:

band aid: identify the shapes, then . . .

position and glue the 'pad' shape over the top;

other elements as shown have double shapes

which should be layered and attached together

for added dimension;

pill bottle - layer outlines, then layer onto base.

10. Position the elements into their respective

windows. NOTE: heart beat ends need to be

tucked under the side edges of frame;

pill shapes are placed inside and to the side of

the bottle shape.

Position and attach the words shape across

the upper left corner diagonally, as shown.

Here is the completed card.