This 3D model is intended to replicate

an ancient hand-held clay oil lamp.

Perhaps you will use it as a teaching tool to recount

the New Testament Parable of the Ten Virgins.

Assemble parts for

lower “bowl”, upper dome,

wick spout and curved handle, with

layered-for-thickness

lower “foot” and upper round rim. The vessel top opening

is sized to optionally hold a standard 1.5” diam. base

LED tea light inside a

tube insert.

Glyphic low-relief decorations on hull dome

suggest hand inscribed

details.

When fully assembled, model measures

approx. 5.875” front to back x

4” wide x

1.875” tall (at handle top).

(Recommended for crafters with some

dimensional project experience.)

Stock material note: this project uses

Encore textured cardstock in gingerbread,

which can be procured from 12x12cardstock.com.

ASSEMBLY: 1. Identify and cut the shapes:

1 right dome 2 left dome

3 top opening "rim" rings (3 to stack for thickness)

4 bowl "floor" oval octagon with center dash guideline

5 right bowl wall segments (8 unique with numbers

and with tiny notches cut in top tab edges)

6 left bowl wall segments (8 unique with numbers)

7 bowl base oval octagons (3-4 to stack for thickness)

8 "foot" rim oval octagon rings (3-4 to stack)

9* left scribe design underlays (shown with dbl

scroll design layers plus solid backer - 6 sets)

10* right scribe design underlays (shown with dbl

scroll design layers plus solid backer - 6 sets)

(*see Step 14 for explanation of scroll scribe depth)

12 & 13 opt. edge rim strips (8 unique position shapes

for left and right; right has 'R' symbol) kept

within their organization rectangle until needed

14 spout upper panel 15 spout lower panel

16 handle panel

If planned, these are the LED tea light insert

shapes to identify and cut:

17 insert tube strip with bottom edge multi tabs

18 circle for bottom of tube

19 platform strip with top & bottom edge

multi tabs

20 bottom "ring" panel to allow fingertip access

21 platform upper circle panel

22 LED tea light cover with hole for "flame"

PRE-ASSEMBLY2. Locate the top/bottom center dash mark on

each of the top opening rings, then carefully stack all

together and glue with top layer face up so

that the center marks are clearly visible.

Take care that ALL cut edges are as precisely

heavy object such as this fabric-covered re-purposed

bar from a weight machine, a thick book or equivalent

and leave in place until thoroughly dried, one or more

hours or overnight. Pressing will help minimize

warping or curling of glued stacked shapes when

using liquid adhesive.

(Repeat the pressing process for each of the following

glued-up stacks.)

as precisely aligned as possible, and glue together.

guide line (NOT a perforation line!) and set aside.

the stacked bottom panels with all outer edges

aligned as precisely as possible and glue together.

6. Beginning with the left side of the bowl and

the 8 left* wall segments, prepare each by

bending back on all perforations for wall portions

and tags. Identify the tiny number

symbols cut into the top tabs - then select #1.

7. Apply glue to the bottom (narrow end) tab, then

position and attach it behind the first straight edge

segment of bottom "floor" octagon panel, on

the right top half next to the dash center guide line.

Take care at each step to align shape edges exactly at

corresponding perf lines of attaching shape so that

the bowl will be the accurate finished size for

assembly which follows.

8. Locate #2 wall segment, then add glue to bottom

tab, position it next to segment #1 and under panel,

adjust for accuracy, then attach in place.

9. Add glue to the edge tabs of #1 segment, then

bend #2 edges into position, one at a time, to position

and attach in place, creating the bowl shape.

10. Continue in the same manner to locate wall

segments in order 3-8, position and attach bottom tabs,

then bend into position and attach to previous segment . . .

. . . until the final left segment is placed.

NOTE that it completes the half and is next

to the opposite center dash guide mark from

where the walls attachment began.

segments, beginning with #1 segment which will begin

next to left #1 to form the spout wall shaping.

When the final segment is placed, the bottom tab

will be positioned and attached to the "floor" panel

in the usual way, but both of the side edges

will overlap and be glued to tabs to neighbor panels.

12. Position the bottom "base and foot" assembly

on the bottom of the bowl with the center top and

bottom angles aligned with the "floor" panel

as precisely as possible. Invert the assembly with

base downward on flat surface and place something

that matches the inside "floor" area shape plus is

taller than walls inside the bowl, with something

like a heavy book on top to weight and press

the bottom to ensure a thorough and non-warped

joining. Consider using quick-grab, (alcohol based)

adhesive that will characteristically warp less.

Allow glue to sufficiently dry.

DOME ASSEMBLY

13. Identify the right and left dome shapes by locating

the tiny circle cut outs near front (spout) end at

upper tabs. Single hole is left side; double is right.

at each wall segment and at top opening edge

curved perf lines. Bend end tabs back also.

for highest degree of depth, stack 2 scroll underlays

plus solid panel; for lowest depth, use only solid panel.

15. Stack and glue together scroll underlays.

NOTE that the final dome cut file omits the scroll

cut out design in the center back panels where they

would be obscured by the handle.

16. On the backside of first dome half panel,position scroll stack so that design cut edges

align with dome cut design as precisely as possible

and attach.

17. Position and attach solid panel on top of

17. Continue to prepare scroll underlay stacks,

position in each dome segment, and attach plain

panels in similar manner. Make sure that scroll

underlay side edges do not interfere with the slight

bending of the dome.

segments. Apply glue to first bowl tab, then

position dome tab to overlap and align exactly

at the bowl tab perforation line. Apply fingertip

21. Bend the dome shape to position, align and

attach the next segment to corresponding bowl

22. Continue in the same manner to work along

the edges and tabs until all 8 of left half are attached.

23. Position the center back tab of second dome half . .

. . . then proceed to attach dome to bowl segment

tabs around second half until dome and bowl

are completely joined.

24. Position, adjust and attach the tab seam

at center front of dome.

25. Position the top opening ring stack over the top

tabs of dome, adjust so that center front and center back

dash guide marks are at front and back center seams,

and attach in place. NOTE that quick-grab glue is

recommended here if available.

LAMP EDGE ACCENTS

26. Dress up the outer lamp edges with wrap-over

narrow strips if desired. There are 8 unique position shapes

for left and right halves and segments.

NOTE that right set has 'R' symbol. Keep the strips

within their organization rectangle until needed for

easier identification.

Begin with the right set, and locate #2 (numbers

are cut into the carrier rectangle). Remove from carrier

and carefully bend back at the perforation.

Apply adhesive to backside of strip, then position it

to wrap around the joint of the right half's #2 segment

edge, next to the spout shaping. (The #1 segment position

is omitted because of the spout placement.)

27. Continue in the same manner to dislodge #3 strip,

bend, then position and attach at corresponding

segment edges through #8 on right half, and

all of strips for left half segments.

SPOUT AND HANDLE ASSEMBLY

28. Prepare the upper and lower spout shapes

by bending back on all perforation lines for tabs

and panels. NOTE that these shapes are laid

out here to simulate how the tips will join.

29. Position the angled edges together for the first

"side" seam where split tabs will allow for the slight

bend of the upper shape. Adjust and attach this seam

and allow to dry until secured.

30. Form the spout into a cone to align the second

side seam, overlap straight edge to opposite

perforation line, adjust and join. NOTE that

the narrowness of the form may require the insertion

of a press-against tool such as the handle of

a spatula or weeding tool to reach into the top.

31. At tip, bend the tiny triangle tabs inward then

apply glue to these. Next . . .

. . . bend the end panel down into place, adjust

as needed, then apply fingertip pressure until secure.

Set aside until final assembly steps.

32. Prepare the handle shape by bending back

on all perforation lines for panels and tabs.

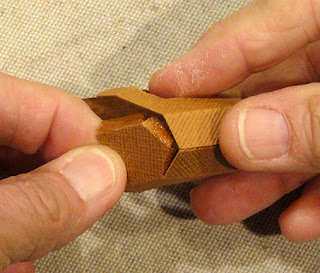

33. Begin assembly at top back by applying dabs of

glue to the two small tabs at the inward angle, then . . .

. . . apply glue to the first ridge tab.

Bend the shape to bring together the plain long

edge to overlap the long tab opposite, while also

directing the small tabs under the edge edges.

Secure the seam as quickly as possible, then . . .

. . . adjust and apply pressure to secure the small

end tabs.

34. Repeat Step 33 for the second ridge seam.

35. At the forward end, apply glue to the three tabs

of the end panel, then slide it into place at the handle

end so that each angle and corresponding edge

align as precisely and neatly as possible.

This is how the end panel should appear

when the seams are complete.

FINAL ASSEMBLY

36. Prepare to attach the spout by bending the side

tabs back/under.

Apply glue next to ring rim edge, and

to these tabs, then . . .

. . . position over the top of the lamp assembly so

fold edges line up at the first segment seams.

Make sure that the "rim" end triangle tab is tucked

under and edge can attach where glue was applied

near ring. Hold in place until joining is secure.

37. Apply glue to underneath tabs, then bend back

into position and apply fingertip pressure until

each is secure. NOTE that the lower edge of spout

should abut at or near "foot" ring.

38. Position handle to insert inward end tabs into

hull slots and fully push inside. Apply glue to sideward

surfaces of tabs (this is a bit tricky), then reach inside

to bend tabs away from center and hold in place

to attach under back segments.

39. At lower back, apply glue to the swing-away panels,

then adjust so they align at center bowl seam,

and hold in place until secure.

The simpler version of the lamp is now complete.

For authentic look, consider obtaining a short length

of cotton wicking and inserting it into the spout hole.

(This is the more correct way that an oil lamp functioned.)

LED TEA LIGHT ADAPTATION

40. Identify the tube insert's "floor" circle by

the tiny notch cut into the edge.

41. NOTE that the side tab of the strip DOES NOT get bent

back as a more normal tab would have.

DO NOT BEND BACK.

Use a narrow dowel or similar rod-like tool to

add a moderate amount of back curl to the insert strip.

Bend the tiny tabs back.

42. Form the strip into a tube to overlap the straight end

edge to the guide line dash cuts, adjust top to bottom

and join the seam.

43. Apply glue either to the backside of each of

the tiny tabs (preferred) or . . .

. . . to the equivalent margin along the edge of

the floor circle back side. Then . . .

. . . insert the floor circle into the top opening of

the insert tube and . . .

. . . press completely down to rest against the bent

tabs. Apply fingertip pressure around and around

the bottom until all of the tiny tabs are secured.

44. In a similar manner, prepare the platform insert

(which will hold the LED tea light up into position)

following Steps 42-43, with the exception that

platform includes tiny tabs along both long edges.

Apply glue to tabs or ring, then insert and secure

as for insert tube.

45. With platform top edge tiny tabs up in "open"

position, insert the whole platform top circle inside,

appl glue to backside of tabs, bend tabs toward center.

Invert the platform with whole side downward

on work surface. Insert fingertip(s) through ring opening

to apply pressure all around to secure whole circle seam.

46. Insert the platform into the insert tube (this is

a tight fit) as shown, and push fully down.

47. Place the cover ring over top of tea light, and

insert into tube . . .

. . . and push fully down to rest on top of platform.

48. Place the LED insert tube assembly into

the center opening of the lamp and push fully down.

Remove tea light only as needed to activate flame light.

Here is the completed lamp with tea light.

No comments:

Post a Comment