Imitate popular large metal marquee letters

with

this miniature version.

Bulbs of 20 light mini set from Darice

(wreath applications

are suggested by mfgr.)

are pushed through holes and held in place

by built-up

ring "collars" (shown in model as white

to amplify mini lights;

can

be made to match letter body if preferred).

Letter edges are built up with

slightly deeper "flanges",

cut individually to make adjustments easier

due to card stock paper thickness.

Mini light battery canister is

camouflage-encased

in a sized-to-fit box with lid and cutouts

with on/off

switch accessible.

Built up foundation shape is included

to attach letters and

battery box.

Letters measure approx. 6" tall x 1.5" deep.

Overall

display (not including foundation extension

for battery box) is approx.

10.75" wide.

LIGHTS SET INFORMATION :

The mini lights set that is used for this project

is by Darice: Deco Lights teeny bulbs 20 lights, which

is battery powered (hence the artwork that is

shown as part of the battery housing though the

2 "C" batteries are NOT included).

The product number ID is BT20-1 white wire/clear teeny bulb.

Scan code numbers: 652695539725

One package costs under $5.

I purchased mine from JoAnn Fabrics walk-in store.

They are also available on-line from many locations.

With batteries in place, a metal level is pivoted

to make the connection that sends power

to the string of lights.

When lit, the lights put of virtually NO heat.

Packaging text includes: "Great for

centerpieces. Glue on Wreaths."

However, it is not recommended to leave the

lights on for extended periods of time,

nor to leave them unattended.

Suggested use of this product for this project

on this blog does NOT constitute any responsibility

on the part of Jodi G. Warner or SnapDragon Snippets

for any problems/damage caused as a result

of the light malfunction or combustion.

ASSEMBLY:

1. Identify and cut the shapes for the letters

(cut one B, two O):

A main "B" hull shape B extra side boxing

C interior opening boxing upper & lower

D inner vert support struts (2)

E outer & inner edge flanges (see more below)

F collar rings (8 per opening x 20 for BOO)

G main "O" hull shape H vert struts (2)

I interior opening boxing strip

J outer edge flanges K inner edge flanges

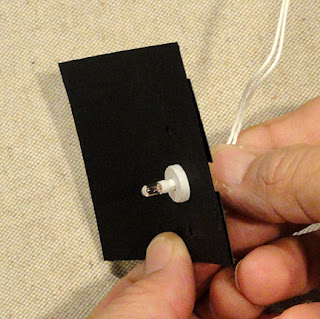

This is an out-of-focus (apologies) shot

showing the thickness of the 8 layer built-up collar.

to bring the side straight edge to overlap on

the inside of the side tab, adjust and glue in place.

Repeat for the other boxing shape.

6. With the "B" housing laying face down on work surface,

identify the upper opening boxing assembly,

and note that the narrow panel indicated here . . .

. . . will line up with the narrow lower corner panel

indicated here.

make adjustments as needed.

Work for the best, most accurate alignment

possible.

boxing addition that creates the boxing at B shape's

right edge indent near center by bending center perf

inward and tabs back.

Position and attach this addition at corresponding

side tabs, and attaching top tabs under the "B" edges.

interior openings by noting that for each opening

there will be one narrow and one wide.

side edge over side tab.

(Tab should be behind strip edge, showing

from the back side of the assembly.)

lay them side by side on work surface,

align bottom edges to be even as they will

be when the assembly "stands".

Apply "quick grab" adhesive to the faces that will touch

(such as the hot glue being added here,)

then carefully attach the letters into one unit.

the left side (as viewed from the front) . . .

wire section into the front "B" bottom hole . . .

(another view of the first light insertion)

. . . then continue to string the lights up and around

the "B", using the notches in the support struts

to help the wires string as required.

Then string the wire over the attached "B" and "O"

walls to insert in bottom "O" hole, up and around,

then across to the "O", etc.

28. Gather the excess wiring behind the battery

and band with tape if desired.

Tuck into the bottom of the B.

Also tuck the wires into the letter backs

as thoroughly as possible.

NOTE it may be advisable to use small strips

of electrical (black) tape to manage the wire.

The mini lights set that is used for this project

is by Darice: Deco Lights teeny bulbs 20 lights, which

is battery powered (hence the artwork that is

shown as part of the battery housing though the

2 "C" batteries are NOT included).

The product number ID is BT20-1 white wire/clear teeny bulb.

Scan code numbers: 652695539725

One package costs under $5.

I purchased mine from JoAnn Fabrics walk-in store.

They are also available on-line from many locations.

With batteries in place, a metal level is pivoted

to make the connection that sends power

to the string of lights.

When lit, the lights put of virtually NO heat.

Packaging text includes: "Great for

centerpieces. Glue on Wreaths."

However, it is not recommended to leave the

lights on for extended periods of time,

nor to leave them unattended.

Suggested use of this product for this project

on this blog does NOT constitute any responsibility

on the part of Jodi G. Warner or SnapDragon Snippets

for any problems/damage caused as a result

of the light malfunction or combustion.

ASSEMBLY:

1. Identify and cut the shapes for the letters

(cut one B, two O):

A main "B" hull shape B extra side boxing

C interior opening boxing upper & lower

D inner vert support struts (2)

E outer & inner edge flanges (see more below)

F collar rings (8 per opening x 20 for BOO)

G main "O" hull shape H vert struts (2)

I interior opening boxing strip

J outer edge flanges K inner edge flanges

L battery box housing

M base platform build up (4)

Th design of these letters includes separate

edge flanges which have a fold-down top rim

that extends approx. 1/4" beyond the platform

where the lights and collars extend..

Each flange is attached to a specific "face"

around the outside and also inner openings.

Being separate, they can be trimmed down

if necessary, which may be necessary due to

varying thickness of card stock used.

Our usual "tolerances" for textured card stock

was used in the sizing. I used 110#

which is slightly thicker, and some trimming

was necessary.

Below are the "B" flange shapes laid out

in their approximate positions around the B

1-6 are for the outer edges. 7 group is for

upper interior opening. 8 group is for

lower interior opening.

Groups 7 & 8 include the same shapes,

but their positioning is horizontal mirrored.

2. Prepare the mini light collars build up,

which help hold the lights in position.

Position and glue together a stack of 8 rings

for each of the 20 lights in the set.

This can go quickly, but TAKE CARE that

the edges line up as precisely as possible.

My choice for the sample project was to make these

white and place them on the outside face of

the letters.

Other good choices: i) make them match housing;

ii) place them on the underside of the housing

so that they don't show.

showing the thickness of the 8 layer built-up collar.

3. Position and attach one collar at each light hole

opening on the "B" main shape. Make sure they

attach firmly. It may be helpful to use a flat

weight during the glue-drying process.

4. Prepare the interior opening boxing shape

by bending forward on all the vertical perforation lines,

and bending top edge tabs back.

REMEMBER that the upper and lower openings

will required their specific boxing, so make sure

that both the shapes from the cut file are cut.

The lower boxing includes an "X" cut in the side tab.

5. Form the interior boxing shape into a ringto bring the side straight edge to overlap on

the inside of the side tab, adjust and glue in place.

Repeat for the other boxing shape.

6. With the "B" housing laying face down on work surface,

identify the upper opening boxing assembly,

and note that the narrow panel indicated here . . .

. . . will line up with the narrow lower corner panel

indicated here.

7. Apply glue to the face of upper edge tabs

of interior boxing, then position over the

backside of the opening, taking care to align

the edges of the opening with the tab perforation

lines. Complete initial alignment, then . . .

. . . quickly turn assembly to front tomake adjustments as needed.

Work for the best, most accurate alignment

possible.

8. Form the B hull into its "box" shape by bending

the edges into position to complete the seams.

Straight edges should overlap adjacent tabs

to perforation lines.

During this process, prepare the double panelboxing addition that creates the boxing at B shape's

right edge indent near center by bending center perf

inward and tabs back.

Position and attach this addition at corresponding

side tabs, and attaching top tabs under the "B" edges.

9. Prepare the "B" vertical support strut strips

by bending end tabs back in opposite directions

as shown.

Position and attach on the inside of "B" assembly

flush next to the interior opening boxing back side,

attaching end tabs to top and bottom

in the same step. NOTE that notches face out.

Shown here is the back strut.

Also position and attach . . .

. . . the back strut in the same manner

10. Prepare each edge flange by bending back and

creasing the top rim perforation. Glue rim tab in place.

11. Identify the narrow flanges for the "B"interior openings by noting that for each opening

there will be one narrow and one wide.

12. Apply adhesive to the back side of flange

below rim tab, then position over the corresponding

face, bottom edges even, top edge of hull snugly

abutted to the rim tab lower edge.

Begin with the narrow flanges, here the narrow upper . . .

. . . then the lower wider flange . . .

. . . then continue with the remaining flanges,

first testing it in position to note any trimming

for appropriate length that may be necessary,

then applying adhesive and attaching.

13. Repeat the process for the outer edge flanges,

including the "double" indent flange shown here . . .

. . . then adding the remaining flanges all around.

14. The process to assembly the "O" form is similar.

First, prepare the main hull shape by bending

back on ALL perforation lines . . .

. . . positioning and attaching collar "stacks"

at each light opening.

15. Prepare the interior opening boxing strip

by bending forward on all vertical perf lines,

bending back on top tabs.

NOTE that the narrow interior panels for the "O"

are all the same width.

16. Form the strip into a ring to overlap straightside edge over side tab.

(Tab should be behind strip edge, showing

from the back side of the assembly.)

17. Position and attach the interior boxing

to the underside of the "O" hull in the same

manner as for the "B" (step 7).

18. Bend edges in place to complete the "O"

side seams in same manner as for "B".

19. Prepare, then position and attach the

interior flanges, beginning with the narrowest . . .

. . . then measuring, trimming if necessary,

and adding the other flanges around.

Also position and attach the outer flanges.

20. With all three letters completed,lay them side by side on work surface,

align bottom edges to be even as they will

be when the assembly "stands".

Apply "quick grab" adhesive to the faces that will touch

(such as the hot glue being added here,)

then carefully attach the letters into one unit.

21. The letters can be used independent of

the base platform, if desired. With the platform,

the battery will be more easily dealt with.

Without the platform, the battery could be "hidden"

behind nearby objects in your display.

* * *

Prepare the platform by layering and attaching the

multiple cut shapes (sample uses 4 shapes of 110#;

cut and build up your platform with as many layers

as is necessary for sturdy base. Take care that

edges align as precisely as possible.

22. NOTE that the battery box assembly

and battery will be demonstrated in its

"unattached" form first. Once its assembly

is understood, it will be necessary to

to remove the battery housing itself in order

to attach the box to the platform (step 26).

* * *

Prepare the battery box by bending back on

all perforation box lines and tabs except

the insertion tabs of roof flaps should be left unbent.

23. NOTE that the right back side seam tab

will be left unattached to allow for the battery

wire to slide into place.

Fold the sides of the box upward to bring together

side straight edges to overlap adjacent side tabs,

and complete the other three seams . . .

. . . leaving the back right seam unattached.

24. Place the battery container (with batteries inside)

into the prepared box with the activation switch

toward the top as shown . . .

. . . direct the wires across the front and alongthe left side (as viewed from the front) . . .

. . . and out the back opening where the side seam

is unattached. If desired, close the seam with

temporary adhesive such as adhesive roll-on dots, etc.

25. Close the top of the box by bending into

position, inserting the side and back tabs into

corresponding slots.

26. Position and attach box bottom

on the platform extension,

with the lever opening toward the very back,

and the three punch holes of each aligned.

27. This cut-away will show how the mini lights

are inserted and pushed fully

into their openings with collar.

Insert the first light beyond the long attachmentwire section into the front "B" bottom hole . . .

(another view of the first light insertion)

. . . then continue to string the lights up and around

the "B", using the notches in the support struts

to help the wires string as required.

Then string the wire over the attached "B" and "O"

walls to insert in bottom "O" hole, up and around,

then across to the "O", etc.

28. Gather the excess wiring behind the battery

and band with tape if desired.

Tuck into the bottom of the B.

Also tuck the wires into the letter backs

as thoroughly as possible.

NOTE it may be advisable to use small strips

of electrical (black) tape to manage the wire.

Here is the lighted assembled display to this point.

29. Position (centered) the letters on the front of

the platform panel, and attach with

quick grab glue (such as hot glue).

Here is the completed display.

No comments:

Post a Comment