Dimensional frames in 6x6 and 5x7 each light up

with 20 battery-powered (cool to the touch)

"Deco Lights teeny bulbs" by Darice.

Recessed frame platform provides base for photos,

printed card or other artwork, or dimensional cutouts

for special occasions, celebrations or seasonal holiday decor.

Mat frame inserts are available as separate cut files

to fit the two frame sizes, with 5x5 window or 4x6 window

respectively. Six mat layers stack to create beveled inner edges.

Models are shown in card stock that matches the marquee

frame base. Custom coordinate your paper to each project.

(all available through SnapDragonSnippets.com, SVG Attic,

or Silhouette America's online store).

Let your imagination reign to come up with

fun ways to use these two designs.

Here, the 6x6 marquee has print (without mat) . . .

. . . and here is 5x5 artwork showing through the mat.

Here is 5x7 artwork (without mat), and . . .

. . . here is 4x6 artwork showing through mat opening.

LIGHTS SET INFORMATION :

The mini lights set that is used for this project

is by Darice: Deco Lights teeny bulbs 20 lights, which

is battery powered (hence the artwork that is

shown as part of the battery housing though the

2 "C" batteries are NOT included).

The product number ID is BT20-1 white wire/clear teeny bulb.

Scan code numbers: 652695539725

One package costs under $5.

I purchased mine from JoAnn Fabrics walk-in store.

They are also available on-line from many locations.

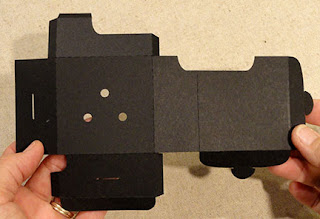

ASSEMBLY: 1. Identify and cut the shapes:

5x7 FRAME

A main frame front, sides and top

B main frame bottom "add-on" panel

C main frame inner top & bottom panels

D vertical interior support strips (2)

E circle collar (light supports) (120)

F outer side, top & bottom flanges

(we suggest cutting from 110 lb. card)

G battery pack base H battery pack box

I inner platform main shape

J platform diagonal cross supports (1 ea. of 2)

NOT SHOWN:

short interior supports (4; see Q, below)

5x7 MATT

K mat "frame" layers 1-6

L modified (shorter depth) platform for use with mat

M modified platform cross supports

Take care to make sure the inner opening

edges are as precisely aligned as possible.

One way to do this is to insert a pointed tool

such as an awl or knitting needle tip into the

interior circle as the gluing together proceeds.

Apply sufficient pressure to ensure good adhesion

between the layers.

The frame will require 20 of these stacks.

the front of the frame.

(Select one position, either front OR back.)

13. Apply glue to backside below top rim flange,

then position first side along the outer frame edge.

Adjust to make sure the panel is even with both

end edges of main frame.

Repeat for second side flange attachment.

back edges are all flat against surface.

. . . direct the wires across the front and along

the left side (as viewed from the front) . . .

This image shows that the light PLUS the

collar should "pop" through to the front.

holes in order, helping connecting wires to

cross over the interior supports at the half-circle

notches placed for that purpose.

and first inserted light (for management of wires)

and wrap a piece of electrical tape to keep

them bundled. Tuck into the bottom back recess.

and face side up.

Position and attach frame 2 on top of frame 1 . . .

taking care that all OUTER edges line up

as accurately as possible.

This correct alignment creates a slightly offset

margin of frame 1 to remain visible,

creating the "bevel" edge simulating a

framer's cut mat.

33. Continue to position, align and

attach frames 3-6 on previous mat assembly

with the same outer edge alignment care as noted.

NOTE it will be helpful to use a large flat

weight during the gluing/curing process

to help avoid warping.

5x7 FRAME

A main frame front, sides and top

B main frame bottom "add-on" panel

C main frame inner top & bottom panels

D vertical interior support strips (2)

E circle collar (light supports) (120)

F outer side, top & bottom flanges

(we suggest cutting from 110 lb. card)

G battery pack base H battery pack box

I inner platform main shape

J platform diagonal cross supports (1 ea. of 2)

NOT SHOWN:

short interior supports (4; see Q, below)

5x7 MATT

K mat "frame" layers 1-6

L modified (shorter depth) platform for use with mat

M modified platform cross supports

6X6 FRAME

N main frame front

O inner opening top, bottom panels

P interior vertical supports

Q short interior supports (5-6)

R outer side flanges (2 sides; 2 top, bottom)

S battery pack base T battery pack box

U circle collars (120; for light bulb supports)

V inner platform main shape

W platform cross supports

6x6 MAT

X mat frame layers 1-6

Y modified (shorter depth) platform for use with mat

Z modified platform cross supports

NOTE: Both size frames have very similar

assembly. The model shown in these assembly

steps will be for the 5x7 frame.

2. Prepare the main frame shape by bending back

on all panel and end tab perforations.

3. Prepare the bottom add-on panel by bending

back on the top tab perforation line.

4. Position and attach bottom panel

at the bottom center of the main frame

shape. Ends should align between the

side panel perforations, with straight frame

edge aligned exactly at perforation line.

5. Complete four corner seams by bending

the side or top, bottom panels into position

to overlap the straight edge at the tab perforation

line, and gluing the seam.

6. Prepare the interior panel add-ons by bending

back along the tab perforation line.

7. Position and attach add on panels to the

straight edge of interior top and bottom opening

in manner similar to previous panel seam.

8. Complete all four interior corner seams

by bending side, top or bottom panels back,

with end tabs bent forward, then aligning

straight panel edge along adjacent tab perf line.

9. Prepare the collar circle "stacks" by

layering eight (8) circles, one on top of the previous,

until . . .

. . . together they form a thick collar.Take care to make sure the inner opening

edges are as precisely aligned as possible.

One way to do this is to insert a pointed tool

such as an awl or knitting needle tip into the

interior circle as the gluing together proceeds.

Apply sufficient pressure to ensure good adhesion

between the layers.

The frame will require 20 of these stacks.

Position and attach one collar at each frame

punch hole.

For the frames project, recommended position

is on the backside of the main frame,

so they provide support to the light shaft

but do not show on the front.

Another alternative is to attach them tothe front of the frame.

(Select one position, either front OR back.)

10. Prepare the vertical interior supports by

bending the pair of split end tabs in

opposite directions, as shown.

11. Apply adhesive to the end tabs, also to the

face of the support that will align and attach

to the inner face of the opening side wall.

Position support strip (centered top to bottom)

with notches facing upward (away from frame)

next to the backside of the side wall, with

end tabs attaching to the top and bottom walls.

Adjust as necessary to make sure the ends

are NOT pushing the panels out of square.

12. Prepare all four outer flanges by bending

back top rim tab and gluing to the backside

of the strip.

then position first side along the outer frame edge.

Adjust to make sure the panel is even with both

end edges of main frame.

Repeat for second side flange attachment.

14. Position and attach top, bottom end flanges

in the same manner.

15. Prepare center platform by bending back

on all panel and end tab perforation lines.

16. Complete corner seams by bending

side or top, bottom panels into position

to overlap straight end edge at adjacent

end tab perf line.

17. Prepare the platform cross support strips

by bending the tabs in opposite directions.

Assemble the cross support by sliding the

strips together at the center slots until they

interlock with top straight edges flush.

18. Position and attach cross support on the

underneath interior space, directing the strip

ends into the corners, and gluing the tabs in final

position to the platform back side.

19. Apply glue to the platform outer side, top & bottom

panels, place on flat surface, then position

the frame assembly over platform, and

slide into position . . .

. . . pushing downward until frame and platformback edges are all flat against surface.

20. Prepare the short cross supports by bending

side split tabs in opposite direction.

Add glue to tabs, then position and side into

place between frame inner and outer panel walls

approx. one-third of the way in from end walls.

Attach 2 per side for the 5x7 and 6x6 frames, with

addition 2 per TOP only of 6x6 frame.

21. Prepare the platform by layering and attaching the

multiple cut shapes (sample uses 4 shapes of 110#);

cut and build up your platform with as many layers

as is necessary for sturdy base. Take care that

edges align as precisely as possible.

22. Position the base stack back extension

on the inside bottom of the frame assembly

between the vertical support strips,

and glue in place.

NOTE that the battery box assembly

and battery will be demonstrated in its

"unattached" form first. Once its assembly

is understood, it will be necessary to

to remove the battery housing itself in order

to attach the box to the platform (step26).

* * *

23. Prepare the battery box by bending back on

all perforation box lines and tabs except

the insertion tabs of roof flaps should be left unbent.

NOTE that the right back side seam tab

will be left unattached to allow for the battery

wire to slide into place.

. . . leaving the back right seam unattached.

Fold the sides of the box upward to bring together

side straight edges to overlap adjacent side tabs,

and complete the other three seams . . .

24. Place the battery container (with batteries inside)

into the prepared box with the activation switch

toward the top as shown . . .

the left side (as viewed from the front) . . .

. . . and out the back opening where the side seam

is unattached. If desired, close the seam with

temporary adhesive such as adhesive roll-on dots, etc.

25. Close the top of the box by bending into

position, inserting the side and back tabs into

corresponding slots.

26. Position and attach box bottom

on the platform extension,

with the lever opening toward the very back,

and the three punch holes of each aligned.

NOTE this image shows how the box

will be aligned, using the punch trio to help

orient the box correctly.

WAIT until lights are inserted before

actually attaching battery box in place on base.

27. Begin with the first light above the battery

pack, inserting the tip bulb and the connected

"collar" of the light into . . .

. . . and through the punch hole.This image shows that the light PLUS the

collar should "pop" through to the front.

If the light bulb is difficult to get through the

collar, consider opening the hole slightly

with a tool such as this awl, pushed into hole

and twisted as pressure is applied to

expand the opening slightly.

28. Continue to add lights in sequence intoholes in order, helping connecting wires to

cross over the interior supports at the half-circle

notches placed for that purpose.

Also, tuck the excess wire down into the

recesses of the frame between walls.

29. Bundle the excess wire between battery boxand first inserted light (for management of wires)

and wrap a piece of electrical tape to keep

them bundled. Tuck into the bottom back recess.

30. Position and securely attach battery pack

box onto the base.

MAT ASSEMBLY

31. Identify the mat frames by the order numbers

1-5 cut into the frame shapes.

Number 6 will be top frame shape and

does not include a cut number.

32. Place frame 1 on flat surface, number and face side up.

Position and attach frame 2 on top of frame 1 . . .

taking care that all OUTER edges line up

as accurately as possible.

This correct alignment creates a slightly offset

margin of frame 1 to remain visible,

creating the "bevel" edge simulating a

framer's cut mat.

33. Continue to position, align and

attach frames 3-6 on previous mat assembly

with the same outer edge alignment care as noted.

NOTE it will be helpful to use a large flat

weight during the gluing/curing process

to help avoid warping.

34. Insert the mat build up shape

on top of the platform to finish the frame.

(Of course, either position and attach

artwork first, or remove mat and attach.)

NOTE: use the modified platform

and cross supports when using the mat

with the frame. This will allow mat to

continue to be slightly recessed from frame face.

No comments:

Post a Comment