Here's a Halloween project with a vintage feel -

at least that was the aim, geared to the experienced crafter.

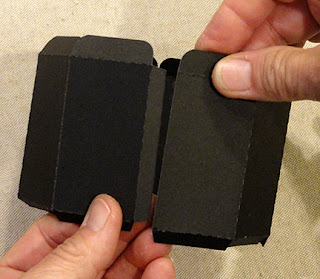

Dimensional black cat head (model is grey-ish instead) is a box

that has dimensional ear and cheek add-ons,

with side extensions, layered eyes, tongue and whiskers.

a colorful ribbon bow tie dresses him up.

A rounded-tip pleat rosette serves as its base.

(Lid optional shapes included with hex cutout

to accept the cat head neck post end,

as alternative without rosette.)

(Lid optional shapes included with hex cutout

to accept the cat head neck post end,

as alternative without rosette.)

Below, a ten-sided "round" box with lid acts

as the cat's base. Box has optional doily for lid,

with accents for lid rim and box sides.

Measures approx. 5.5" tall x 4.5" wide

x 3.125" deep.

NOTE: If you purchased and downloaded this design

from Silhouette America or SnapDragon Snippets

prior to 9-28-2018, you will need to

RE-DOWNLOAD

the corrected copy.

NOTE: If you purchased and downloaded this design

from Silhouette America or SnapDragon Snippets

prior to 9-28-2018, you will need to

RE-DOWNLOAD

the corrected copy.

ASSEMBLY: 1. Identify and cut the shapes:

A main hull head shape B trap door cover

C outer ears left and right

D inner ears left and right

E neck post with closed bottom

F neck post interior support rectangle frame

G neck post interior support struts (2)

H alternative neck post shape with open bottom

with bottom opening cover (use with box lid,

without rosette)

I dimensional nose

J check "cups" left and right

K jowl extensions

L layered nose accents

M eyebrows left & right

N eye assembly left and right

O tongue

P rosette pleated strips (2)

Q rosette centers (2)

BOX SHAPES:

R lid main shape S lid rim strips (2)

T lid rim accent shapes (5)

U lid offset accent V lid doily shape

W base bottom ('X' at center)

X base outer bottom (tiny notch at edge)

Y base side wall strips (2)

Z side wall accent strips (5)

positioned . . .

straight edge over opposite tab to perf line

and glue seam.

perf lines to form the frame, then overlap end

over opposite tab and glue the seam.

C) insert the 'X' struts corner-to-corner

inside the frame, and . . .

. . . push together until all top

and bottom edges of all are even.

11. Insert the support unit into the neck post

interior between two parallel walls . . .

of the head assembly by applying adhesive to

the face side of the bottom tabs.

and push completely through to tabs.

Glue tabs in place on the interior bottom panel.

down over tabs, adjust so that perf lines/bends

line up with lid edges, and glue in place.

perforation line roughly vertical, narrowest portion

outward, and bend back on perf line.

B) position and glue pupil circle, centered, over

eye base circle, and transfer the perf bend to it.

C) layer together: lid accent over lid base;

nose accent over nose accent base;

eye slit with highlight over slit base

so that tabs can insert into the slots, then push

tabs all the way through . . .

. . . position over eye assembly, with bend over

head ridge, and glue in place.

through all layers behind the cheek shape;

D) insert needle point through head trap door

and through one of the whisker holes . . .

. . . and pull all the way through until knot catches

behind face.

E) trim whiskers roughly to size; final trim comes later;

F) repeat for all whisker holes on both sides of face;

together and complete second seam.

Hold in place . . .

pleats inward to smallest circle possible,

with evenly spaced pleats, until glue cools

and circle is secure.

On backside, apply more hot melt glue to

attach backside circle cover.

overlap the straight edge (shown on right here)

over the side flange tab opposite to perf line,

adjust for top-to-bottom alignment, then glue seam.

locating the small 'X' cut into the center.

Add glue to the inside face of each of the bottom

tabs, then . . .

the bottom panel is securely in place.

41. Position and attach the outer bottom panel

(with notch) on the bottom of the hull to conceal

the tab construction.

bending each back at the vertical perf line.

in similar manner as for hull walls.

glue each in place.

the cat can be built with the tab-bottomed neck

(at this point in assembly, the neck would be

attached to head; this is intended as

demonstration only).

The neck post bottom tabs would be inserted

through the hex cutout opening . . .

over the tabs and opening, attaching in place.

A main hull head shape B trap door cover

C outer ears left and right

D inner ears left and right

E neck post with closed bottom

F neck post interior support rectangle frame

G neck post interior support struts (2)

H alternative neck post shape with open bottom

with bottom opening cover (use with box lid,

without rosette)

I dimensional nose

J check "cups" left and right

K jowl extensions

L layered nose accents

M eyebrows left & right

N eye assembly left and right

O tongue

P rosette pleated strips (2)

Q rosette centers (2)

BOX SHAPES:

R lid main shape S lid rim strips (2)

T lid rim accent shapes (5)

U lid offset accent V lid doily shape

W base bottom ('X' at center)

X base outer bottom (tiny notch at edge)

Y base side wall strips (2)

Z side wall accent strips (5)

2. Prepare the main head hull shape by bending

back on all panel and tab perforation lines.

3. Form the hull into a tube shape to bring

the back straight side edge to overlap the opposite

back-side tab to perf line, adjust for top and bottom,

and glue in place.

4. Bend the top wall segments inward to align

the straight edges to overlap the adjacent tabs

to perf lines, and glue seam.

Continue to work from back to front along both

sides to align and glue all angled seams, until . . .

. . . the final two side-front seams can be completed

in more or less one action.

Bend all top segment tabs inward at perpendicular angle.

Bend the top panel (with eye slots) into position,

adjust edges and segments as necessary

to align top panel edges with tab perf lines.

Use the trap door to access seam to assist gluing.

5. Repeat the segment seam joining process

to complete the seams along the bottom of the hull . . .

. . . until the front/bottom panel segment ispositioned . . .

. . . and attached, adjusting as necessary.

6. Prepare the neck post shape by bending back

on all perforation lines.

(NOTE the model uses this shape with closed bottom;

optional open bottom can be substituted to

allow post bottom tabs to be inserted through opt. lid

shape hex opening - see Step 53 middle.)

7. Form the neck shape into a tube to overlapstraight edge over opposite tab to perf line

and glue seam.

9. Bend bottom wedge tabs inward

to perpendicular angle, then bend bottom "lid"

into position to glue in place.

10. Prepare the interior support shapes:

A) position 'X' strut strips with up or down slots,

then interlock them and push fully down.

B) bend the rectangle frame back on all verticalperf lines to form the frame, then overlap end

over opposite tab and glue the seam.

C) insert the 'X' struts corner-to-corner

inside the frame, and . . .

. . . push together until all top

and bottom edges of all are even.

11. Insert the support unit into the neck post

interior between two parallel walls . . .

. . . and push together until top edges (excluding tabs)

are even as shown.

12. Prepare the insert the neck post into the bottomof the head assembly by applying adhesive to

the face side of the bottom tabs.

Position the neck post into head interior through

back trap door, then . . .

. . . insert bottom end out through hex opening,and push completely through to tabs.

Glue tabs in place on the interior bottom panel.

13. Prepare the ear shapes by bending back

on all panel and tab perforation lines.

14. Bend top wedge tabs inward, bend top "lid"down over tabs, adjust so that perf lines/bends

line up with lid edges, and glue in place.

15. Prepare the inner ear as shown, by bending

forward on long angled perf lines, narrow edge flanges,

and bottom edge rounded tabs.

16. Prepare the attach the inner ear to

corresponding outer ear by noting the outer

side tab (outer ear) and longer side wall (inner)

which will correspond to each other when

assembled correctly.

Position inner ear into front cavity of outer ear

(wrong sides of paper together) . . .

. . . and line up flange long edge at outer ear side long edge

for both sides, with "rounded" top tabs also aligning

at inner ear under "lid". Glue flanges/tabs in place.

Bend bottom tabs upward/outward.

17. Prepare the attach the each to the head hull

by applying glue to the inside face of curved portions

of center two panels of outer ear.

Position ear assembly with longer SIDE extension

tab toward head side panel slot, shorter TOP tab

lining up with top-of-head slots.

Insert tabs into corresponding slots, then . . .

. . . urge the back panels over the corresponding

panels of head back, and glue in place.

Also reach into head through trap door to

attach tabs to head inner walls.

Repeat for both ears.

Also apply a dab of glue at the bottom portion

of ear above side tab (between head and ear wall),

then apply pressure to attach the two layers.

18. Prepare face feature components

by first laying out the shapes.

Prepare left and right set of eyes.

A) orient the eye main base shape withperforation line roughly vertical, narrowest portion

outward, and bend back on perf line.

B) position and glue pupil circle, centered, over

eye base circle, and transfer the perf bend to it.

C) layer together: lid accent over lid base;

nose accent over nose accent base;

eye slit with highlight over slit base

D) layer lid assembly over top of eye circles assembly

and attach; transfer vertical bend to all layers.

E) attach eye slit assembly centered below lid

19. Prepare jowl extensions by bending back

on perforation.

Position over front of lower head, with slot and

partial slot lined up with corresponding slots on head;

glue in place where shapes touch.

20. Prepare the cheek "cups" by bending back on

perforation lines. Form a pyramid or cup shape by pivoting

and bending at perf lines, to bring the straight

panel edge to overlap the opposite tab perf line;

glue tab in place.

21. Position over the lower cheek "point" of head

on top of the jowl, aligning the front lower nose slot;

glue in place.

22. With both cheeks and jowl extensions in place,

position and attach the top of the tongue in place

between and below.

Add a little curl to tongue before attaching.

23. Prepare the dimensional nose shape

by bending back on panel perf lines, bend side

and bottom tabs outward.

24. Bend the side and bottom panels inward

slightly to overlap straight edge over wedge tab

to perf line and glue seam; repeat for opposite seam.

25. Position and attach nose accent assembly.

26. Position the nose assembly over front of headso that tabs can insert into the slots, then push

tabs all the way through . . .

. . . and bend tabs back inside head and glue in place.

27. Position the appropriate eye assembly

with bend corresponding to

the head ridge, with eye bottom touching

top of jowl, and glue in place.

28. Bend the eyebrow at perf dash, then . . . . . . position over eye assembly, with bend over

head ridge, and glue in place.

29. Position the trap door cover at back of head

and glue over the trap door opening.

UNLESS

you plan to attach twine whiskers;

delay attachment of cover in that case.

30. Twine or perle cotton whisker addition will be

shown next. As alternative, consider inking the whisker

punch holes with marker to accent them.

OR . . .

use a darning needle and soft twine or perl cotton yarn:

A) cut a length of twine, thread onto darning needle,

and tie a knot at tail end;

B) add a dab of glue to the knot;

C) use darning needle tip to pre-punch a holethrough all layers behind the cheek shape;

D) insert needle point through head trap door

and through one of the whisker holes . . .

. . . and pull all the way through until knot catches

behind face.

E) trim whiskers roughly to size; final trim comes later;

F) repeat for all whisker holes on both sides of face;

31. Position and attach the trap door on head back.

ROSETTE

32. Prepare the rosette accordion strips by

beginning at the half-arch tip end (right in photo)

to bend in "valley" fold, then alternate mountain/valley

folds until entire strip is folded.

33. Join the two strips by overlapping the whole arch tip

end over the half tip end, and glue the joint.

34. Form the long strip into a ring to bring free endstogether and complete second seam.

35. Begin to form rosette by flattening the accordion

ring onto work surface, arched tip ends outward,

and gently force the sides inward to narrow

the center circle, until . . .

. . . pleats are as tightly narrowed as possible.Hold in place . . .

. . . as hot melt glue in applied in ring around

center opening, then quickly . . .

. . . attach cover circle, then continue to forcepleats inward to smallest circle possible,

with evenly spaced pleats, until glue cools

and circle is secure.

On backside, apply more hot melt glue to

attach backside circle cover.

BOX ASSEMBLY

36. Prepare the box hull side wall panels by

bending back on all panel, tab and side flange

perforation lines.

37. Align side edges of the two panels tooverlap the straight edge (shown on right here)

over the side flange tab opposite to perf line,

adjust for top-to-bottom alignment, then glue seam.

38. Form the walls assembly into a ring to bring

remaining wall side edges together to complete

the second side seam.

39. Bend the bottom tabs inward at

perpendicular angle.

40. Identify the box exterior bottom panel

by locating the small partial circle notch

on one edge; set this one aside.

Identify the interior box bottom panel bylocating the small 'X' cut into the center.

Add glue to the inside face of each of the bottom

tabs, then . . .

. . . insert the interior box bottom into the hull

and slide it down into position so that each

straight edge seats snugly along a segment bend.

Apply finger tip pressure along each edge untilthe bottom panel is securely in place.

41. Position and attach the outer bottom panel

(with notch) on the bottom of the hull to conceal

the tab construction.

42. Bend the upper hull tabs inward and glue

each to the inside surface of the hull.

43. Prepare the hull side accent shapes bybending each back at the vertical perf line.

44. Attach each panel centered with perf line angle

matched to an angle of hull, with approx. .12" offset

margin at sides and bottom.

(The upper portion is left "free" to allow

the lid to fit snugly."

45. Prepare the lid rim panels by bending back

on all perforation lines.

46. Join the two sections by attaching ONE endin similar manner as for hull walls.

47. Position a top panel edge along first segment

of the rim assembly, taking care that the edges

match up "corner to corner" as accurately as possible,

and glue in place.

48. Continue to bend the rim strip to align the strip

to position and join each subsequent segment

to corresponding top panel edge until the final

segment only remains.

Position it and the final end seam (under-lapped)

in one step to join both to the appropriate edges.

49. Bend the rim side tabs back inward andglue each in place.

50. Prepare rim accent shapes by bending back

at center perf line, then . . .

. . . position each with perf angle aligned at

rim angle, with upper edges also aligned.

51. Position and attach the top accent panel.

52. Position and attach the doily accent shape.

Fit the lid over the base to complete the box.

(This is a snug fit.)

OPTIONS FOR ATTACHING CAT HEAD:

53. Head with closed bottom neck can be

hot-melt glued directly onto the center of lid

as shown here.

Or, for a more integrally connected head,the cat can be built with the tab-bottomed neck

(at this point in assembly, the neck would be

attached to head; this is intended as

demonstration only).

The neck post bottom tabs would be inserted

through the hex cutout opening . . .

. . . and tabs would be bent outward and

attached to underside of lid.

(NOTE: this connection IS NOT possible when

also using the rosette base.)

Conceal the post opening by placing the circle shapeover the tabs and opening, attaching in place.

54. The model is shown with the cat base rosette

positioned and hot-melt glued to the lid, then

the closed-bottom neck of cat head is hot glued

at the center.

Here is the rosette version in place,

ready to have ribbon bow tie attached at neck.

No comments:

Post a Comment