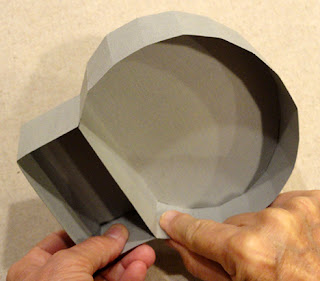

Wood block style 3D box composed of

angular lid and

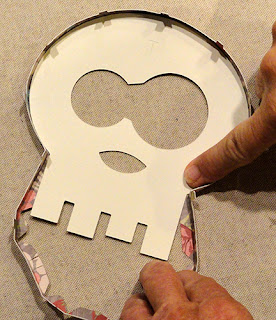

base that fit closely together. Bump-out skull with

recessed

eye sockets and nose fits onto front panel

with tabs and slots.

Layered-for-thickness

eyeballs with pupils

(or substitute large stud jewels) add a spark of life.

Great

as a base-standing decoration with

lid and base walls glued together,

or use as

a gift box with lid and base that can be

opened and closed.

Block box measures

approx. 6” tall x 5.72” wide

x 1.5” deep (plus .3 deep bump-out) when closed.

(Requires 12x12 cutting capacity and card stock.)

(This tutorial is under construction.

Please return soon to view

the completed assembly guide.)

ASSEMBLY: 1. Identify and cut the shapes:

A LID front panel

B LID upper boxing strip C LID lower boxing strip

D BASE front panel

(Not shows is the BASE panel overlay

that is attached on outside bottom of BASE)

E BASE upper boxing strip

F BASE lower boxing strip

G BASE cross brace boxing strip

H LID front panel overlay with slots

I eyes contrast J bump out assembly front panel

K bump out upper & lower narrow boxing strips

L bump out eyes and nose openings narrow boxing

M bump out front panel overlay

N large eye ball layers (8) and pupil layers (4)

O smaller eye ball layers (8) and pupil layers (4)

Compare the front panels so that they are used

in the correct positions. At left in this image, the LID

front panel overlay includes slots. At center, the LID

assembly front panel includes the 'L' symbol.

At right, the BASE bottom panel that includes 'B',

and not shown, the outer bottom panel which is blank.

Also NOTE that the boxing strips for LID and BASE include

tiny symbols near ends that indicate how ends

join. Single symbols indicate LID strips; double

symbols indicate BASE strips.

2. Complete the "pre assembly" steps so that glue-ups

can be drying as other assembly is completed:

A) layer & attach the large and small eye ball circles into

separate stacks of 8, taking care that outer edges

and hole punch edges are aligned as precisely as

possible;

B) layer & attach the pupil circles into

separate stacks of 4, taking care that outer edges

are aligned as precisely as possible.

Press the glued-up stacks under a flat heavy weightuntil thoroughly dried, for several hours or over night.

This will help prevent warping or curling of multiple

shapes glued with liquid adhesive.

on front of the LID front panel overlay (with slots).

3. Prepare the BASE upper boxing strip by bending

back on cross perforations for segments and end tabs,

and back for bottom tabs.

on cross perforations and tabs in similar manner . . .

. . . then join the strips at ends as shown by

. . . then join the strips at ends as shown by

to the tabs interior surface all around. Insert the BASE

panel (with 'B') face down into the boxing, adjust

so that center top, side angles and bottom corners

side and bottom flanges. Position at the middle angle

of BASE compartment so that side tab perforations

align at angle perforations, then . . .

taking care that edges align as closely as possible

to box edges. Apply pressure to ensure attachment.

8. Repeat steps 3-5 to complete the LID in

similar fashion.

9. Bump out form is composed of front panel,

curved boxing strip for upper curved edge,

a rod-like tool such as this round shaft pencil.

Bend the small tabs ALL back.

10. Bend the lower strip to match the crenelation

Bend the small tabs ALL back.

10. Bend the lower strip to match the crenelation

the straight line tab cuts will bend forward.

downward, apply glue to tabs backside

orient so that mid-side angles align with

pressure to layers at beginning of upper (rounded)

portion until they are secure in place,

then . . .

. . . apply fingertip pressure all around to firmly

attach in place, allowing the strip to adjust if needed

to the rounded shape so it is even and well fitted.

13. Apply glue to tabs backsides along lower strip,

then bend to fit between the 'teeth' crenelations.

Apply pressure to snug the bends to hug

the panel edge.

Use a spatula tool or equivalent to further assist

getting the boxing to fit the panel edges.

This is the bump out assembly as completed

to this stage.

14. Prepare the eyes opening bump out boxing by

bending back slightly at the cross perforation lines

for the narrow straight portions near end tab

and at mid point.

Also add tight forward curl

using round-barreled pencil or similar tool.

15. Form the strip into a "ring" and join seam.

Bend edge tabs back, and make sure that ALL

cut tab-defining edges and disconnected.

16. NOTE that the straight edge tabs should be

ON TOP of the curved edge tabs as the strip

is attached behind the eye opening edge.

With bump out assembly face down apply glue

to upper straight edge ONLY. Fit the upper straight edge at

corresponding opening edge, align tab edge as precisely

as possible to panel edge, and

. . . apply fingertip pressure

until firmly attached. Repeat this preliminary step

for the lower straight edge, at corresponding panel edge.

17. Apply glue around backside at (between panel

and strip tabs) at opening edge of large OR small

opening for the approx. width of tabs. Then work to shape

strip so that perf bends align at panel opening

edges as precisely as possible.

18. Repeat step 17 for the remaining portion

of opening and unattached strip tabs.

Apply pressure all around to secure strip at opening edge.

19. Prepare the nose bump out strip in similar manner

to add curl, position with corresponding upper and lower

oval edges at panel opening edges, make adjustments,

and attach tabs in place, etc.

20. Position and attach bump out overlay panel.

21. Position bump out over the LID front panel

overlay and align tabs with slots, then insert tabs.

At backside, bend tabs inward and glue in place.

(Quick grab adhesive such as Fabri-Tack is suggested.)

22. Position large and smaller size eye ball stacks

in place within eyes recess, aligning punch holes

of discs with those on panel/contrast panel.

Position pupils stacks, centered over punch holes.

Apply pressure to securely attach in place.

If desired, position and attach large size black

low-relief studs on top of pupils to provide highlights.

23. Position the bump out/overlay assembly over

LID front panel and attach securely in place.

(Quick grab glue recommended.)

24. To close the box, insert the BASE within

the LID, then . . .

. . . slide fully together.

If you plan to use the box as a BOX, do not apply

glue between layers. However, if this will be

a decoration only, it may help to snug the two layers

together by applying quick grab glue between

at side angles and other strategic placed all around

as deemed necessary. Apply hand pressure for

accurate and full attachment.

No comments:

Post a Comment