Dimensional tray has subtle hourglass shape

with

sturdy walls and rim accents.

Designed to be used as a base for candles . . .

. . . and a greenery

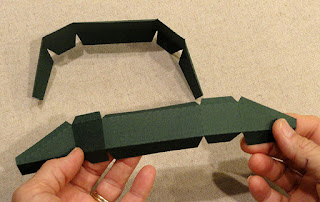

centerpiece

with narrow candle trio at center,

filled with various sprig and pine cone elements.

Angled platform structures are included

as

attachment base for greenery.

Tray is also appropriate as a serving tray for

loose candy and other goodies.

Measures approx. 11.25" long x 6.375"

wide x 1.5" deep.

(Centerpiece assembly will follow construction steps

for the tray, after Step 25 .)

(Centerpiece assembly will follow construction steps

for the tray, after Step 25 .)

ASSEMBLY: 1. Identify and cut the shapes:

A main hull base

B hull bottom cover C hull inside (top) cover

D side walls arch (2)

E side wall outer accent overlays (2 sets)

F left inside side wall extensions (2)

G right inside side wall extensions (2)

5. Arrange the two hull shapes so that the ends

are inward as shown.

Slide the two seam edges together,

tucking the tab under the opposite straight edge

on the side, and . . .

. . . the shaped tab that is an extension

of the rim under the opposite rim . . .

. . . and urge hull halves together until the straight rim

edge matches up to the tab dash cut,

and glue together all overlapping surfaces.

. . . applying fingertip pressure along the seam edge

from the inside of the hull,

until all edges are securely attached and

glue is dried.

guide line along the side four angles for side wall.

pushed to far back.

Attach both wall sections into hull.

the side wall end tabs, and also nudge the bottom

flange back until it is at position exactly at

perforation guide line.

To help provide a press-against surface to

complete the seams, insert a skewer or other rod

tool into the bottom panel openings and adjust

so that it is behind the seam being completed.

Move tool to other holes to help press other seams.

Complete both ends of inner walls.

the back/bottom cover.

on the vertical perforation lines and on upper edge

tabs and bottom flanges.

to align the next straight edge along top tab perf line,

and glue in place.

. . . apply glue to the flanges and also

to the front flange of panel . . .

. . . then insert into tray ends, with approx. .375"

space between all edges and tray interior wall,

and attach in place.

Candles trio or larger hex candle can easily fit

in the flat tray space between the platforms.

30. Position cedar sprig short shapes at tray

sides, overlapping end evergreen sprigs as shown.

It may be helpful to bend cedar stem tip to help attach.

to the stem of each pine cone, using quick-grab

glue such as hot melt. Curl the end to provide

a glue-up surface.

A main hull base

B hull bottom cover C hull inside (top) cover

D side walls arch (2)

E side wall outer accent overlays (2 sets)

F left inside side wall extensions (2)

G right inside side wall extensions (2)

Also cut two sets of the rim accent shapes.

2. Prepare the hull side walls shape by bending back

on all perforation lines, taking care

NOT to bend the horseshoe-shaped rim area

of the shape.

Bend the center flange tab forward.

3. Position and attach the side outer wall

accent panels offset approx. .1" within the panel

perforation perimeter folds.

4. Bend the side walls back to line up the adjacent

panels, overlapping the straight edge over

the opposite tab, and glue side seam.

Complete all four seams on two side wall units.

are inward as shown.

Slide the two seam edges together,

tucking the tab under the opposite straight edge

on the side, and . . .

. . . the shaped tab that is an extension

of the rim under the opposite rim . . .

. . . and urge hull halves together until the straight rim

edge matches up to the tab dash cut,

and glue together all overlapping surfaces.

6. Fit the hull bottom panel into the hull assembly

(shown here from the bottom between side wall flanges)

then invert the tray and fit the bottom panel edges

snugly down into position, with edges matched

up to each wall segment bottom flange perforation line.

7. Apply glue to bottom flanges, then apply pressure

to the side walls all along to ensure that walls

stay snugly around bottom panel edges,

while also . . .

from the inside of the hull,

until all edges are securely attached and

glue is dried.

8. Hole openings on hull bottom panel are provided

to allow a tool to be inserted to assist gluing

of inner wall seams later in the assembly process.

Use scissors to carefully trim away excess

bottom flanges so that openings are clear.

9. Prepare the inside left and right walls by

bending upper and side flange tabs back,

and bending bottom flanges forward.

Identify the small L or R symbol cut into the outer end

tabs.

10. Pair one left with one right for two sets,

then join the center seam (center tab DOES NOT have

a letter symbol cut) of each set as shown.

12. Identify the small letter symbol cut into the end tabs

of each wall section, (as shown, the 'R' will be

on the LEFT end of the set).

The R end will attach to the RIGHT end of

the hull's end wall.

Apply glue to the top flanges of one wall unit, then . . .

. . . apply glue to the margin behind the dashedguide line along the side four angles for side wall.

13. Fit the wall under the rim and slide into place

to match the rim straight edges along the flange

perforation lines, while also positioning

the bottom flange straight edge . . .

. . . to line up exactly at the base perforation guide lines.

It may be helpful to use a tool such as the spatula

shown to help nudge the edges into place.

A weeding tool "hook" may help if walls getpushed to far back.

Attach both wall sections into hull.

14. Apply glue to the end flange of the left

and right wall sections, then . . .

. . . apply glue to the margin behind the guide

perforation line at hull ends.

Bend the end inner wall into position to overlapthe side wall end tabs, and also nudge the bottom

flange back until it is at position exactly at

perforation guide line.

To help provide a press-against surface to

complete the seams, insert a skewer or other rod

tool into the bottom panel openings and adjust

so that it is behind the seam being completed.

Move tool to other holes to help press other seams.

Complete both ends of inner walls.

15. Apply glue then insert the interior panel

cover and . . .

. . . apply pressure all around edges to ensure

that it seats into position completely.

16. Apply adhesive, position and attachthe back/bottom cover.

17. Position and attach the rim accent strips

onto all rim angles.

Here is the completed hourglass tray.

18. Platform inserts with an angled surface

are included in the cut file to build and insert

into the tray to provide a surface to attach

greenery.

For the pair of platform inserts, cut the shapes

as shown here:

H platform panel

I side and back boxing strip wall

19. Prepare the platform panels by bending

bottom flange forward slightly.

20. Prepare the boxing strips by bending backon the vertical perforation lines and on upper edge

tabs and bottom flanges.

21. Position the back long straight edge of panel

along the long upper tab, adjust for end alignment,

then glue in place.

22. Bend the next boxing wall segment into positionto align the next straight edge along top tab perf line,

and glue in place.

23. Repeat the alignment and gluing process

for the final angled seam.

Complete the seams for the second side tab

sequence for this platform.

Complete both platform insert units.

24. Bend the bottom flanges inward, then . . . . . . apply glue to the flanges and also

to the front flange of panel . . .

. . . then insert into tray ends, with approx. .375"

space between all edges and tray interior wall,

and attach in place.

Candles trio or larger hex candle can easily fit

in the flat tray space between the platforms.

GREENERY CENTERPIECE

The following steps will explain the greenery,

tray and candles centerpiece.

25. Here are the finished elements used in

the centerpiece project:

A hourglass tray B platform inserts

C candle 3D trio

D cedar sprig center (2)

E cedar sprig sides (2 left & 2 right)

F cedar sprigs short (3 left & 3 right)

G evergreen sprigs - long (8)

H evergreen sprigs - short (4)

I ponderosa sprigs (4)

J boxwood sprigs (2 long & 2 short)

K pine cones (4) L ribbon bow & "found" berries

26. Position and attach platforms, candles trio.

27. Position and attach left & right cedar sprigs

and center cedar sprig as shown at tray end.

28. Shape the evergreen long sprigs by carefully

curving into an arch, so the sprigs can flow

over the tray rim slightly, once in place.

29. Position and attach four long evergreen sprigs

spaced across the tray end assembly as shown.

sides, overlapping end evergreen sprigs as shown.

It may be helpful to bend cedar stem tip to help attach.

31. Position and attach stem ends of

two ponderosa sprigs as shown

(one near center, one forward).

32. Position and attach cedar center sprig

to overlap previously-attached sprigs.

33. Position and attach two short evergreen

sprigs as shown (one at center, one forward).

34. Position and attach long boxwood sprig

just back of center, short boxwood sprig forward.

35. If desired, attach a length of floral wireto the stem of each pine cone, using quick-grab

glue such as hot melt. Curl the end to provide

a glue-up surface.

Insert the pine cone stems/wires down into

the greenery and glue two in place.

36. Repeat Steps 27-35 to fill and arrange

the second half of tray. If there is space around

the candlesticks near the center as there was

with the sample project, tuck and attach brown paper

shred bunches down to conceal the tray base

and platforms that still show through.

37. Tie a ribbon bow, then position and attach

to the rim center front.

Add other embellishments as desired

(sample project has twisted twigs, floral berries,

and teardrop berry picks added.

Enjoy your paper floral centerpiece project.

Is there a video anywhere showing how to put this together, Im not good just with pics. Great design.

ReplyDeleteSorry, I only do still photos for turorials.

Delete