Create

a perky mitten standing "box" to celebrate

the winter season and add an accent to

seasonal decor,

for December and Christmas, or January

and snowy weather. Or just for fun!

Nordic snowflake motifs with oversized “yarn” cut outs

suggest knitting

patterns and wrist ribbing on

layered-for-thickness front and back panels.

Separate compartment is assembled with reinforcing

accent boxing overlays, then

attached between the panels.

Fill this unique container with loose sweet

treats,

silk greenery or seasonal stems or picks,

add tissue paper-wrapped

gifts for birthday,

get well or cheery greetings for Valentine's Day

or other occasions.

Project

measures approx. 7.375” tall x 5.5” wide

x 1.375” deep when fully assembled

(interior container is somewhat smaller).

Consider adding one of the the Nordic

Heart tags

(separate designs) as a finishing touch.

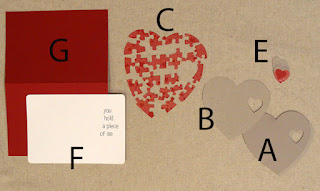

ASSEMBLY: 1. Identify and cut the shapes:

A-C mitten FRONT & BACK panel layers:

for each -- the sample project uses

blue face plate, 3 inner kraft,

cream back face

D left & right interior compartment main front, back panel

E thumb compartment front, back panel

F bottom reinforcement stack (3-4 layers to match E)

G right side with bottom boxing strip with accent overlays

H left side boxing strip with accent overlays

I thumb extension boxing strip with accent overlays

2. Prepare the Front and Back panel stack by quickly applying liquid adhesive between the layers of front

(or back) cut out shape then carefully layering so that

ALL cut edges align as precisely as possible.

Make sure the punch hole for hang tag is aligned as each layer is added.

Back layer should match the interior container layer. Immediately press stack under a flat heavy weight such as this thick book, possibly with something else

heavy on top, and leave in place for several hours or

over nighty. This helps minimize warping or curling of

paper layers when using liquid adhesive.

3. To provide strength and reinforcement for bottom of interior compartment "floor", layer the bottom strips,

align cut edges precisely as these are glued into

one stack. Press until dried.

4. Visualize how the front and back layered panels will look and be configured when the compartment

with boxing is added between. Then . . .

. . . prepare the boxing strips to echo that shaping. Add some back-curl to the top portion of each side

boxing strip in the sections where the small tabs are

(but take care NOT to bend an actual crease into boxing)

using a narrow rod-like tool such as the wooden dowel shown.

Also bend at the cross perforation lines, bending forward or back as the shape of the panel suggests.

At the small "round" opposite the thumb extension, bend the upper 2 perforations inward and

the 3rd perforation outward.

For the side boxing that includes the bottom segment, bend inward at a right angle.

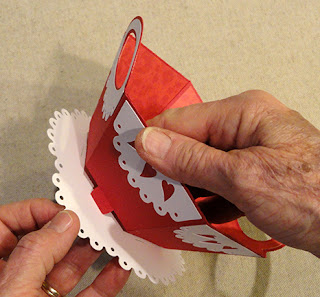

5. Bend the boxing tabs back, then dry-fit the panel edge under the tabs to test where the bends will fit.

(NOTE: when the back panel is positioned, fingertip

pressure access along tabs-to-boxing seam will be

more limited, so the suggestion will be to attach panel

edge on top of the boxing; if preferred to have this

assembly step match, place panel edge on top at

this step as well.)

Apply liquid adhesive along the tabs for the uppercurve segment and . . .

. . . side long segment . . .

. . . then fit those segments along the panel edge, taking care that the top tab perforation and the end

of long segment perforation each align accurately

at corresponding "angles" of panel. Apply pressure

from backside until seam is secure.

6. Apply adhesive to the next segments, then continue to fit them to the edge of panel . . .

. . . with similar care to alignment.

Apply pressure to secure attachment.

7. Position the remaining side boxing strip byoverlapping the straight edge across end tab,

adjusting top to bottom for alignment, then joining.

8. Position it along the panel side edges in manner similar to what was done for opposite side boxing.

Take care that top segment- tab perforation line

aligns with top "corner" angle of panel.

Apply pressure as attachment proceeds.

9. Prepare the accent overlays for boxing by identifying which boxing segments each will attach to, and

arranging for easiest assembly. Add similar back curl

to the top ends of upper strips.

Check that the curl of strip will match boxing as desired, then apply adhesive, position within boxing

segment with small offset margin all around . . .

. . . and attach in place.

For easier fingertip access for applying pressure,invert the boxing strip in question onto flat work surface,

and position fingertips to press from inside.

10. Prepare the next overlay by bending along perforations so that they echo the hull boxing . . .

. . . then position and attach in place, aligning perforations and bends.

11. Continue with bottom overlay, and . . .

. . . the two overlays on the thumb extension side. NOTE that the area where the thumb boxing will

attach is left blank.

12. Prepare the thumb boxing strip by bending back on all perforation lines, including end tabs

(which may be re-bent as needed).

13. Fit the thumb panel inside the boxing tabs and form boxing around panel as much as

possible. (NOTE that there may be some slight

"wiggle room" around end.)

Take care to align ends of panel tips at ends of boxing to allow close fit of thumb to hull.

14. Position and attach accent overlays to thumb . . . . . . bending at perforation lines as required.

15. Prepare the thumb assembly to attach by bending inward along the attachment edge flange.

Apply glue to the flange, then insert the bottom . . .

. . . top thumb large tabs into the appropriate slots

on hull side panel. Push all the way in, then . . .

. . . on the inside, bend the tabs downward and apply pressure to attach to the adjacent

boxing wall. Hold in place until attached.

16. Working quickly, apply adhesive to backside of (thoroughly dried) cut outs panel stack around cut outs,

and also to edges of compartment panel/tabs

(to avoid adhesive erroneously showing or coming

through cut outs. Position the front

centered over the compartment so that the offset

margin of panel is approximately even all around

(except at top which is straight cut). This may be . . .

. . . best viewed when placing the assembly face down on work surface. Hang tag punch hole should remain

visible above the compartment upper edge as shown.

Then immediately apply fingertip pressure all around to ensure that the panel and

compartment are thoroughly attached.

17. Apply glue to underside of "floor" reinforcement panel, then position, centered, inside the compartment

with the bottom boxing segment. Apply pressure

until fully attached, including within thumb area.

18. Close the compartment bending all edge tabs inward, then applying glue to the outer face side

of tabs. Position the compartment back panel over

tabs and opening, adjust boxing as needed to fit curves

and corners or angles, etc., then apply pressure

all along area of boxing seam until fully attached.

19. Repeat the process to position and attach thumb back panel, first bending the inward flange

back into place and applying adhesive to flange face

before tucking it down to attach to side boxing panel.

20. Prepare to attach the back cut outs panel by applying glue around cut outs and along compartment

edges as was done for front panel. Then position,

adjust so offset margin is even all around while also

matching with offset positioning of front panel, etc.,

and apply pressure to ensure good attachment.

This may require reaching inside with hands or

other helpful objects or tools.

21. Apply glue to backside of upper tabs, then bendback fully to attach in place to boxing backside.

22. If desired, prepare one of the Nordic heart tags

(separate designs) by layering front panel over

contrast back panel and attaching in place.

To make the faux stitching cuts show better, use

fine tip pencil or felt tip to carefully fill in the cuts.

If desired, position and attach the back label for

identifying the recipient or signing name, or sending

a short greeting, etc.

Here is the completed project, with heart tag

tied onto front panel at punch hole.