THIS DESIGN HAS BEEN PULLED FROM

SILHOUETTE AMERICA ONLINE STORE,

AND SNAPDRAGON SNIPPETS,

and will no longer be available to purchase

and download.

This tutorial will remain in place,

for those who may have purchased and

downloaded the design before it

was removed.

Large and elaborate paper craft model

can recreate the fantasy of a fairy tale princess

for party centerpiece, or make-believe fun.

Back panel includes a trap door and oversize letter slot

to accept Valentine cards or wedding gift envelopes.

Model measures approx. 15.5" tall x 13.5" wide x 12.75" deep.

Requires 12x12 cutting capacity.

Construction involves preparing components

(square tall towers, front corner octagon towers,

angle nooks, crenelated battlements, front portico) which are

attached in sequence to four main castle walls panels.

(Not a beginner's project.)

ASSEMBLY: 1. Identify and cut the shapes:

A castle front panel (1)

shown with upper window overlay (3)

and bottom window overlay group (3)

and optional window contrast shapes (3 each)

B castle right panel (1)

C castle left panel (1)

R angle tower clover window frame build up (6)

S clover window contrast liner (2)

T tower jewel stone "build up" (12)

U angle tower roof (2)

Y1 and Y2 corner tower roof rim trim (2 each)

Z corner tower roof (2)

CC battlement contrast rim trim (4)

Not shown: build up crenelation shapes (12)

DD battlement build up strips for backside (24)

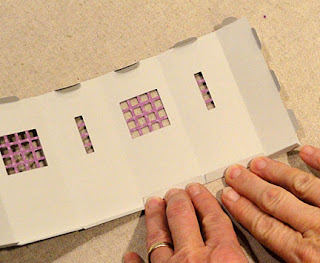

EE spout surround (60)

FF spout tube (20)

A castle front panel (1)

shown with upper window overlay (3)

and bottom window overlay group (3)

and optional window contrast shapes (3 each)

B castle right panel (1)

C castle left panel (1)

D castle back panel (1) with trap door and letter slot

E trap door overlay contrast (1)

F trap door portcullis overlay (1)

G trap door hinge perforation reinforcement (1)

H circle wrap fasteners (4)

I tall tower FRONT Left (2)

J tall tower FRONT Right (2)

(Not shown: tall tower BACK generic (4)

L tower top opening platform (8)

M tower top opening reinforcement square (8)

N tower bottom opening reinformement (8)

O tower cone roof (8)

P pennant flags (8)

Q angle tower main shape (2)R angle tower clover window frame build up (6)

S clover window contrast liner (2)

T tower jewel stone "build up" (12)

U angle tower roof (2)

V portico main shape (1) with contrast arch rim (1)

W portico roof rim (1)

Not shown: rim support build up (2)

X corner tower main shape (2) with window trim (2 sets)Y1 and Y2 corner tower roof rim trim (2 each)

Z corner tower roof (2)

AA castle roof with overlay (1 each)

Not shown: floor panel with side flanges

BB battlement main shape (4)CC battlement contrast rim trim (4)

Not shown: build up crenelation shapes (12)

DD battlement build up strips for backside (24)

EE spout surround (60)

FF spout tube (20)

MAIN CASTLE WALLS STRUCTURE

2. Identify the main walls by locating the "L", "R", "F" and "B"

cut letters in the shapes. These notations are intended to help

position them correctly, as seen from above the castle structure,

with the FRONT of the castle at the top

refer to the line drawing following the next image).

Prepare the mail castle walls for LEFT, FRONT,

RIGHT by attaching the window trim shapes

around the upper "gothic" and lower "roman" arch windows.

3. Join the three main walls by overlapping the straight

left side edge over the adjoining right side edge tab.

This line drawing should help position

the main walls for the castle structure,

along with the tall square tower structures

as they are prepared and attached.

NOTE that LEFT and RIGHT tall towers

are paired to attach (eventually) to the FRONT panel,

with a RIGHT tower on the forward edge of the LEFT panel,

and a LEFT tower on the forward edge of the RIGHT.

These "left" and "right" tall towers are part of the

"angled wall" structures, with unique slots to accept tabs.

The four tall towers on the back of the castle

(do not include the angled wall slots)

can be used in any of the positions noted.

4. Prepare the BACK castle wall by layering the trap door

(portcullis) base shape with the "bars" shape.

Center and attach it to the back trap door ONLY of the BACK panel,

just above the perforated "hinge" line.

5. Bend the hinge reinforcement shape forward

on the perforation line. Position the fold/line centered

and exactly along the perf line of the wall, and glue in place

where it overlaps the wall and the trap door accent shapes.

6. Layer a pair of circle closures and glue together.

Position and attach one unit (only glue tiny margin

around cut hole to allow for twine wrapping)

over the punch on the wall shape.

7. Cut a length (approx. 8 or 9 inches long)

and thread one end through the door punch hole,

then secure a generous 1/4" tail on the backside.

Knot the free end to keep it from unraveling.

8. Position the circle closure unit over the door punch holeand secure by attaching a small eyelet/rivet through all.

Also attach a rivet through the wall circle closure unit.

This is how the closure and trap door

should look when completed.

FRONT TALL TOWERS

9. Identify the tall towers by locating the

cut "L" or "R" in the side tabs near the top.

10. Prepare the towers by bending back on the

vertical long perforation lines, also

bending the tabs outward.

Bend the top perforation lines for tabs/flanges

as shown, forward for perf line nearest to top edge,

back for second perforation lines.

NOTE: this image shows a front tower shape.

11. Apply glue to the flange area between the perforationlines for the three sections ONLY nearest to the

long side that has the tab/flange.

Press to the backside and apply pressure until secured.

(The final tab will be glued later.)

straight edge to the opposite tab perforation line

to secure the side seam.

13. Apply glue and attach the remaining tab/flange

in position, as was done for others in Step 11.

(Shown here is the BACK tower.

FRONT towers are assembled differently.)

14. Bend the unattached tab/flanges at the inside

top opening of the tower perpendicular and toward

the tower center. Apply glue to the "ledge" that these

tabs now create, and position a hollow square

reinforcement shape into the opening . . .

. . . seat onto the ledge, and apply finger/thumb pressure

(or you may need to use a flat tool like a spatula)

to secure the four sides to the reinforcement.

15. Apply glue to the reinforcement shape,

then insert a full square (with flag stick anchor punch)

on top and secure.

16. To reinforce and shape the bottom of the tall tower,bend forward the bottom square side flanges,

apply glue to the flange backsides,

then insert into the bottom of the tower "tube"

until flange cut edges line up with tower edges.

Apply pressure each seam to secure in place.

ANGLE TOWER ASSEMBLY

17. Prepare the build up for the clover window

by layering and gluing together as precisely as

possible three identical build up shapes.

18. Prepare the main angle wall shape by bending

back on all vertical perforations (except the back side flange

and the door lines should be bent forward - valley fold),

also along top, bottom and side tabs, etc.

19.Position and glue the clover window build up

behind the clover window cutout opening,

matching inside edges as exactly as possible,

attaching build up to the backside of the wall.

20. Position and attach the contrast clover windowshape on the backside of the build up shape,

lining up the outside edges.

(Complete both angle wall units.)

21. Prepare the jewel "post" build up by layering

the 6 square shapes as carefully as possible

so that edges match up exactly.

22. Position the post on 45 degree (on point) angle,

between the top of the doors and bottom

of the window, and glue in place.

Repeat for both angle walls.

23. To join the back seam, bring the lower portion

of the side edges toward the center back, forming

a tube, to overlap the straight edge (on left of photo)

to the tab flange perforation line, and glue in place.

24. Complete the top portion of the seam by

pushing the newly joined seam toward the backside

of the angle wall (door/clover window panel)

to allow the top section tab and edge to

come together to overlap and join.

When the seams are completed, the lower portion

should continue to form a right angle inward

at angle wall center back, while at the same time

the much shorter top portion runs parallel to

the wall front.

25. Prepare the angle tower roof unit by bending

slotted floor forward, adjacent tabs forward,

bending front and back walls (front and back) back.

26. Apply adhesive under where the front wall

inner and outer will touch then press together to join.

(Leave the back wall that is similar to this un-joined

until a later point in assembly.)

27. Form the roof by bending sides inwardto match the floor (trapezoid shape) angle, with

tabs under floor, back bending across back of floor,

with end tab tucked under the opposite side.

Glue the tabs under their adjacent floor

or opposite wall edges.

This is how the roof unit should look

(except that the back fold-down wall

should NOT be attached in place at this point.)

28. Dry fit the roof unit onto the top of the angle wall

by fitting the tab through the slot, and sliding it

downward until it seats against the front top straight edge.

NOTE that the side wall tabs will fit on the outside

of the roof unit.

(Also NOTE that in this image, the back fold-down

roof section is shown already folded down,

which it should not be at this point.)

Once you see where the two components will touch,

remove roof unit, apply adhesive, then re-position

and apply pressure or hold in place until secure.

29. Fold the back ridge section down

over the extension of the angle wall,

and glue in place.

ANGLE TOWER TO FRONT TALL TOWERS

30. Attach the angle tower unit to the left and right

front wall shapes by inserting the side tabs

into the corresponding slots, lower slots for angle side

walls, upper slots for roof portion.

to the side and glue in place.

32. Align and attach the back tabs of

left tall tower into the corresponding slots on left side

of front castle wall . . .

. . . then on the inside of castle structure, press tabsback and glue in place.

(NOTE: this image shows tabs pressed inward.

These can be pressed in either direction

according to whichever seems easiest.)

33. With tower back tabs attached,malign and join the front

long side seam (it may require the use of a long tool to provide

a "press-against" surface to secure the center part of the seam),

and also complete the top rim fold down and gluing.

34. Complete: A) attachment of the other tower that is

part of this angle tower assembly;

B) attachment of the other angle tower assembly;

C) top reinforcement "frame" and whole square (see Step 15)

and bottom tower reinforcement (see Step 16).

BACK TOWERS TO CASTLE STRUCTURE

35. Position and attach the four back tall towers

in a similar fashion, by inserting tabs into

slots, bending back on inside, and gluing in place.

36. Apply glue and insert the Angle Tower roof

"floor" masking trapezoid shape.

CORNER TOWERS

37. Prepare the corner tower shapes by gluing

the window grilles over the openings.

Also bend back on vertical perforations, bottom flanges,

side and top tabs. Glue the bottom rim flanges

in place on backside of shape.

This is how the corner tower lower shapeshould look.

38. Insert the roof shape slots over the top tabs

of the corner tower, bend toward center, and

glue in place. (Complete for two towers.)

39. Prepare the roof trim shape by attaching the short

and long portions at the seamline,

overlapping straight edge to corresponding

tab perf line.

40. Bend trim shape in half the long direction,

and bend back flange/tab outward as shown.

Apply adhesive to the shorter shaped portion only,

then attach the two portions where they touch.

41. Position the rim shape around the edge of the roof section, lining up the flanges with the

angle edges and roof end. Glue in place.

CORNER TOWERS TO CASTLE STRUCTURE

42. Position the corner tower by sliding the

castle structure tall towers and main structure

corner into the matching openings on the roof

of the corner tower . . .

. . . and adjusting until

angle tower bottom tabs fit into the roof slots.

Insert the corner tower wall and roof tabsinto the corresponding slots in castle main structure,

Bend all tabs back on insides of structures

and glue in place.

ROOF STRUCTURE

43. Prepare the roof panel by centering and attaching

the roof overlay accent.

44. Position the roof panel between tall towers

and insert castle wall top tabs into corresponding slots.

NOTE that the roof corners should slide under the

angle tower back wall

Also bend the close-to-corner tabs toward center . . .

. . . then glue the tabs in place.

NOTE it may be helpful to use a small press-against

surface such as the wooden block shown

to reach inside the castle structure and position

behind the area where the tabs are being

pressed and glued into place.

BATTLEMENT STRUCTURES

45. Prepare the battlement shapes by attaching

the top rim accent shapes.

46. Prepare 20 spout tube shapes by bending on

perforations to form a tube, overlapping the

straight edge over the tiny tab, and gluing in place.

Bend back end tabs outward.

47. Insert each spout tube from backside

completely into openings . . .

. . . then glue tabs in place on backside.

48. Layer (build up) the spout collars by gluing

three of the rounded square shapes into a stack,

matching all edges as precisely as possible.

Insert over a spout tube, and glue in place to front.

49. Bend the side tabs back.

This is how the battlement shape should look

when completed.

50. Prepare each of 4 backside large build up shapes

by gluing three shapes into a stack, matching

all edges as exactly as possible.

51. Position on the backside of the battlement

assembly centered between the side tabs,

and with top cutout edges lined up exactly.

52. Prepare each of 4 shorter build up by stacking and

gluing together 6 strips with edges aligned precisely.

53. Position and attach to the bottom of the larger

build up shape, with bottom and side edges

aligned precisely.

ATTACHING BATTLEMENT STRUCTURES

54. Apply adhesive to the side tabs, and along

the bottom of the build up area.

(NOTE: quick grab glue such as Fabri-Tac

is a good choice here.)

55. Slide the battlement shape between the talltowers, positioning the ledge on the roof edge . . .

. . . side tabs aligning flush with inward tower edges.

PORTICO ASSEMBLY

56. Prepare the portico wall by attaching the

arch accent shape to the front around arch opening.

Bend the tabs back, also bend the top vertical perf line

forward, the second perf line back.

Glue the ridge area together, while keepingthe larger "roof" area free as shown.

57. Prepare the rim support reinforcements

by accordion folding the strips, then gluing together

all surfaces that touch, to form a stack.

58. Position each stack on the front side of the

arch panel, approx. a generous 1/4" in from each side,

and glue in place.

59. Position the portico assembly between the frontcorner towers, inserting the back tabs into the

castle structure slots, bending back on the inside

and gluing in place.

Also bend the back side slots and front side

tabs back and glue to the structures

where they touch.

60. Prepare the portico rim by bending the front

and back flanges back as shown.

61. Apply glue to the underside of the back flangeof trim, and to the tops and fronts of the

reinforcement stacks. Position the trim, centered,

over the top of the portico ridge, and hold in place

until secure.

62. Prepare the cone roof shapes by bending

back on all perforation lines.

Form the shape into a cone to overlap the

straight side edge to the opposite side tab flange

and glue in place.

63. Fold the top platform down and glue in place

over tiny tabs. Fold the bottom flanges to the

interior of the cone and glue in place.

64. Prepare the pennant flag shapes by adding

some curl to the center area where perforation

lines indicate. This will assist with the "wrap"

around the flag stick. Then . . .

around the flag stick. Then . . .

at the top and glue in place, then glue the backsides

of the pennant halves together.

In the model, the inner pennants use

4.5" long cut skewer sticks, and outer use 3.5" long,

cut to retain the pointed end.

(Sticks were also painted with acryllic paint.)

65. Finish the pennants by adding the "waving in wind"

curl: add curl forward in the area next to the stick,

and add curl backward near the points.

66. Add "quick grab" adhesive such as Fabri Tac

shown here at the anchor hole in the tower platform,

and also around the edges where the cone folded

flange edges will rest. Working quickly, place the

cone in position, flexing slightly if necessary to fit it

onto the top of the tower . . .

. . . then insert the bottom end of flag stick through

cone top hole (this may require some twisting with

pressure to open the hole to fit your skewer side),

through the cone interior, to rest the point in the

platform hole. Turn flagstick NOW to orient as desired.

FLOOR OPTIONS

67. OPTIONAL: for added strength if the castle will be

used as a Valentine deposit box for school, for instance,

it can be made to be sturdier by sliding the bottomless

castle hull over a seam-taped 8x8x8 corrugated cardboard box.

(Ours was purchased at a UPS store.)

If you choose to include the box, insert it in a "dry fit"to mark the location of the trap door opening,

and the depository slot, then remove box and

neatly cut away the areas marked.

You will also want to use the optional window liners

so that it is NOT the cardboard box that is seen

through the window openings.

68. If you DO NOT use the box insert, cut and prepare

the floor/bottom panel by bending the edge flanges upward

to perpendicular. NOTE that the back flange has a

straight top edge, but the sides and fronts have a slightly

shaped center where the window frames will align.

Take particular care when folding near these narrower

flanges to avoid tearing into the flange.

To position, apply adhesive to the face surface of flanges,

then orient with back edge at trap door (back),

then tuck all flanges inside the castle wall edges to

glue in place.

Reach one hand through open trap door to assist.

Here, again, is the completed castle, as seen from

the side front . . .

. . . and from the side back.

Esse molde não pertence à Monica? Ela disponibiliza free e vcs estão vendendo?

ReplyDeleteIf you have seen a similar design for sale or for free, please understand that the image for that design was available to view and be inspired by on the internet. As the cut file designer for this version, I used that "inspiration" to prepare this different, specially sized and engineered cut file to suit our needs and offer to downloading customers. If you can get their version for free, you may prefer to do that. This version is a cut file, sized to fit over (optional) a corrugated cardboard 8x8x8 box for sturdiness. It also has a separate floor. Different, but similar. You choose the one that suits your needs best!!

DeleteAbsolutely LOVE it!!!!

ReplyDeleteIs this now the complete instructions ?

Also do you have it in print format?

Text descriptions of steps will be added within a day or so. Sorry for the delay. Only available as a cut file.

DeleteYou are so talented Jodi!! I know it took you forever to create and your hard work paid off! love love love!

ReplyDeleteThe owner of the castle project design that was the direct inspiration for this design (from images that are available in the public media, and therefore, in my opinion, fair game as inspiration) has contacted Silhouette America and required them to pull it from their online store. To stay consistent, this design has also been pulled from the SnapDragonSnippets.com store. We apologize to any who may have wished to create this different cut file version, but who will now not be able to (unless the file was already downloaded). One option is to do the online search to find the "free" download for the larger castle (Monica designs?)

ReplyDeleteThis comment has been removed by a blog administrator.

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteHi, I don't have the solid roof piece in my cutting files and do you have written construction

ReplyDeleteDid you purchase from Silhouette America (it should be in one of the two files required for the project)? If you purchased from SnapDragon Snippets, it was a separate "free" file. Contact me for the roof shape if the latter was the case (hearthsewnpatterns[at]yahoo[dot]com)

DeleteHi, I bought the files from Silouette

Delete