Square hull in the “saltbox” style has accent

panels,

see-thru upper windows with detailed frame and sash

built-up overlays,

dimensional front step with layered door

and built-up frame, interior platforms

for strength and stability,

opt. LED tea light cup to illuminate vellum window

panels,

back trap door for votive access.

For a patriotic display, prepare and attach

the

“Flag Colonial Stylized” decoration for hull size,

using optional accent with

punch holes to pierce for

brads to position and “hang” flag if desired.

Measures approx. 4.5” deep x 4.5” deep x 10” tall

plus 1.8” deep leanto add on.

ASSEMBLY: 1. Identify and cut the shapes:

A main hull front and side

B front accent panel overlay

C tall side accent panel overlay

D roof crestline support triangular 'box'

E shaped roof (flat) base with edge flanges and slots

F shaped roof with cut-in connection tab rows

G roof section overlay strips (8)

(not shown: roof angle side fascia overlays)

H front step 'box' with connection tabs

I door wreath: 3 unique shapes to overlay

J front windows array (see larger layout following)

K door base, overlays, top & bottom slats and door frame

(not shown: frame top 'lintel' strips)

L main hull back and side

M back accent overlay with trap door cutout

and separate door overlay

N leanto side accent overlay with slots

O interior lower reinforcement 'tray'

P interior middle reinforcement 'tray' (holds tea light cup)

Q trap door closure 'stop' circles

R tea light cup

S star accent base and overlays for build up (3-4)

U leanto hullV, W & X leanto overlay accent panels

Y leanto base interior accent 'tray'

Z leanto roof panel with side flanges and end tabs

AA leanto roof overlay 'shake' strip (top)

BB leanto roof overlay 'shake' strips (4)

C leanto window assembly

Window assemblies details:

Extra shapes for overlays are cut to layer for

door and windows build up to add dimension.

Each window for main hull and leanto consists of

panes grid base (shown as dark here; changed to match

frame before project was finalized),

frame (2), top sash strip (2) and bottom sash strip (2).

Vellum 'glass' panels are also cut to add behind panels

grid base (for more opaqueness, project uses 2 vellum each)

Door consists of contrast base (to show through slat slots)

slat overlays (2), top & bottom slats (2 each), knob circles (2-4).

Door frame consists of inverted 'U' frame (2) and

upper 'lintel' strips (2).

2. Prepare components that need to be layered

and glued up, pressed and allowed to dry:

A) window frames - layer frame shapes with edges

matched exactly; layer upper and lower sashing;

add sashing strips to top and bottom of frame;

add pane grid behind frame (project's final pane grid

matches the frame, not contrast as shown here).

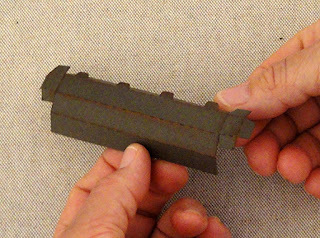

To assist the glued-up assembly to remain flat,to avoid warping or curling that comes with using

liquid adhesive, use a flat heavy object to press flat

during the drying process (hours if possible), such as

the fabric-covered re-purposed weight bar shown here,

or a heavy book, etc.

B) Position and attach vellum panels behind the grid frame.

For this project, a doubled layer of vellum was used

in each window (as shown above), resulting in

very dull tea light show-thru.

After review, a single pane would be more desirable.

C) Position and attach the star accents for build up

(thickening of star), then . . .

. . . position and attach the star to the 'hanger' base.

Press flat while drying.

D) Layer the three wreath shapes with punch hang hole

aligned at top, and adjust layers for best symmetry and

'show through', then glue hang hole ring together,

and a couple of overlapping spots near bottom.

Press flat while drying.

(No images for door assembly)

E) Layer and glue together door panel shapes;

layer upper and lower slats; position and attach slats

to panel assembly; position and attach front assembly

over contrast base; add door knobs as a stack into cut hole.

3. Prepare the front step 'box' by bending back on all

perforations for panels, ends, cut-in tabs.

4. Begin to form the shape into a long narrow box by

bending the end panel tabs inward, then bend ends

back, then . . .

. . . form the long walls into a tube, with

the cut-in tabs allowed to extend outward, long flange

side panel to tuck under, and glue all seams.

5. Prepare the house hull front shape by bending back

on all perforations for panels, side flange tabs, roof.

Position and attach the front and side accent panels,

taking take to align bottom straight edges flush,

and check that cut-out opening edges align as

precisely as possible. If using liquid adhesive

be sure to press flat under a large flat weight

until dried completely (make take several hours).

Otherwise double-stick adhesive such as the tape-runners

is highly recommended for these straight-edge shapes.

6. Position and attach the window assembliescentered over the window cutouts.

Press flat while drying is using liquid glue.

7. Prepare to position and attach the door frame

onto the front panel by identifying the alignment cut marks

on the accent panel, then . . .

. . . position the frame between the sets of marksto center the frame, and also position the bottom edges

to be exactly above the door stop slots.

To double check the height positioning, "dry fit"

the front step in position at lower front edge of panels,

then snug the frame down to touch step upper surface.

Glue in place; press under flat weight until dry.

8. Position the door assembly into the door frame

(this should be a snug fit), and glue in place.

Glue in place; press under flat weight until dry.

9. Prepare the house hull back shape by bending back

on all perforations for panels, side flange tabs, roof.

Position and attach the back and side accent panels,

taking take to align bottom straight edges flush,

and check that cut-out opening edges align as

precisely as possible, like the front hull panel.

Also position and attach trap door overlay

aligned at the right finger hole edges so that

the door can be opened and flexed fully.

NOTE that the 'window' opening in the tall side

is intended to allow tea light candle light

to "spill" into the leanto that is attached at the slots

so that the window is slightly illuminated.

The back trap door allows for the tea light to be

inserted, removed to turn on an off, etc.

are fully aligned so that tabs can be inserted.

Using a tool such as the spatula shown will assist this.

10. Position and align the house hull halves so that

the straight edge of one overlaps the long side flange tab

of the other, to the perforation line, and join the seam.

11. Form the hull into a tube to bring the opposite

edges together in the same manner to complete

the second side seam. NOTE that because they are

symmetrical, the assembly can be laid flat with fingertip

pressure applied along the seam to ensure it is

fully joined.

12. Prepare the lean to hull shape by bending back

on all panel edges, roof angle flange tabs.

Position and attach accent overlay panels as was done

for main house hulls.

13. Position and attach the leanto window assemblyover the window opening as was done for front panel.

14. Bend the side flange down, and roof edge into

position to align and join the seam. Repeat for

the second seam on opposite roof edge.

15. Prepare the leanto base reinforcement 'tray' shape

by bending forward all flanges.

16. Position the tray into the bottom of the leanto

assembly so that the flange edges align along

the bottom edges of the hull, with a slight recess of

the tray. Join all three edges to hull. NOTE that

the unattached inward edge flange should be flush

with the inward side edges of hull, and will be attached

to the house side later in assembly.

17. Prepare the leanto roof base by bending back

along the bottom and sides at narrow wall perforations

and end tabs.

NOTE that corner seams will be joined in step 20.

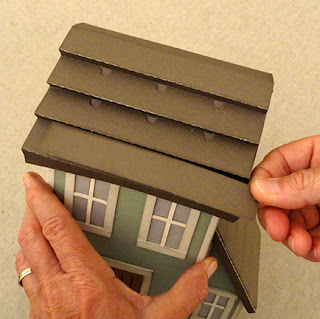

18. Position and attach the roof 'shingles' strips by

centering between side perforations and positioning

top edges at the guide mark dashes. Because of

overlap of lower four strips, the top strip width

is slightly narrower.

19. Continue adding additional strips until all

are in place. Top strip is aligned at top edge.

20. Join the bottom corner seams by forming cornerswith straight bottom end edges overlapping tab

to perforation line, and gluing in place.

21. Apply glue to the bottom tray inward flange surface.

Position the leanto assembly on the left side of hull

and insert tabs into corresponding slots for side walls

and roof edges.

On the inside of main hull, bend the tabs outward

and glue to the backside of hull. Also apply pressure

along the tray flange to fully attach it in place.

22. Apply glue to the leanto roof panel.

Position the roof over leanto hull, insert top side

tabs into corresponding main hull slots and push in fully

so that roof edge abuts the main hull closely.

23. Apply adhesive to the inward front step 'box' surface.

Position under door to insert tabs into hull slots

and fully push in to connect step to hull.

On the inside of hull, bend the tabs down to attach.

24. Prepare the main hull lower interior reinforcement 'tray'

by bending the side walls forward, end tabs in, and . . .

. . . do the same for the middle 'tray'. Join all the corner seams.

25. Prepare the tea light candle cup (if you plan to

use the LED votive to illuminate the house) by

bending bottom tabs under, upper flanges back,

end tab back, and . . .

. . . upper edge tabs forward.26. Bend the octagon 'base' upward (to get it into

position for later attachment), then . . .

. . . form the strip into a tube to bring edges together

to overlap and form seam. Join seam.

27. Apply glue to the underside of bottom tabs, then . . .

. . . push the octagon base down into position to seat

at the tabs bend perf lines, bend tabs inward to glue in place.

Turn the assembly base down and apply pressure

on the interior all around to attach tabs and octagon fully.

28. Apply glue to the inside wall and top tab surfaces,

then bend these into the interior and glue in place

to form the cup. Make sure that they are tightly

attached to the backside of cup wall to create the space

needed to accommodate the tea light.

29. Position the cup onto the top of the middle tray

with center holes aligned.

NOTE: if preferred, TWO tea light votives can be

used to provide more light, including possibly more

into the leanto, in which case, the two cups would be

positioned side by side, covering fingertip holes.

30. Apply adhesive to the outer surfaces of middle tray,

then use fingertip hole openings to hold onto while

inserting the middle tray into the hull through roof opening.

Slide the middle tray downward gradually, maintainingsquared-up positioning, until top edge is aligned at

dash guidemarks on hull panels, a little below

the leanto 'light opening' cutout . . .

. . . as can be seen here through open trap door.

Adjust to make sure it is perpendicular, then

apply pressure all around from outside to attach

securely in place.

31. In a similar way, insert the bottom tray into hull'sbottom opening, adjust so that bottom edges are aligned,

then glue securely in place.

32. Prepare the roof ridge reinforcement 'box' by

bending back on all panel, flange and end tab perf lines.

33. Bend end tabs back, triangle ends inward,

and form triangular tube with long flange tucked under,

and join all seams.

34. When triangle box is fully dried, apply glue to ONE

of the upper surfaces of the triangle only, then . . .

. . . position and attach to one hull roof panel,centered side to side between roof side flanges,

and with crest edge aligned at roof panel top edge.

Apply pressure to fully secure in place.

35. Apply glue to the roof side flange outer surfaces,

(but NOT to triangle box ends)

then bend the roof section into position to align perf edges

to both angled edges of hull's side panels, and glue in place.

36. Apply glue to remaining roof panel side flanges,

and to the final upper exposed triangle box surface,

then bend the roof panel into position to fit the side

flanges inside hull walls between triangle box,

align top crest edges, etc., and glue in place.

37. Prepare the roof base by bending back the side

walls, end walls and side end tabs, and along

center crest line. Align the corner straight edges to

overlap the end tabs to perforation lines and complete

the four corner seams.

NOTE that it may be helpful to achieve a strong

and accurate right angle seam to use a "press-against"

surface behind the seam such as this spatula blade.

38. Prepare the shaped roof by bending back alongthe center crest line, then alternating backward/forward

bending direction going outward from center line . . .

. . . to achieve this configuration. Cut-in tabs should

all be bent back also.

39. For the first tab row attachment, identify

the set of tabs closest to crest line on one side, then . . .

. . . bend the shaped roof FULLY back to allow

those tabs to stick out so that they can be inserted

into the set of slots on the roof base in the top row

next to the center perforation bend.

Once the tabs are inserted . . .

. . . reverse the work to be backside up and bend

the tabs toward the roof end and glue in place

to the roof base backside.

40. Repeat the process for the next row of tabs

to insert them into the next row of slots on base . . .

. . . glue in place on backside, etc., and forfinal row of tabs and slots as well.

41. At the lower roof edge, bend the final 'end wall'

segment down, align edge with edge of base wall,

and glue in place.

with bended shapes, tabs attached in slots, and

over-roof end wall aligned with base end wall.

42. Repeat the process for the opposite side of roof.

43. Prepare to attach the roof to the house assembly

by applying adhesive to both panels of the hull's roof.

Position (centered side to side) and attach so that

roof assembly crest line and hull crest line fit snugly

together as well as roof surfaces. Hold in place until

securely attached.

44. NOTE that the over roof crest line is not attached

to the under roof at this point. To correct this . . .

. . . use a stick or equivalent to reach in and apply

glue between the two layers along the ridge(s), then . . .

. . . press the two roof layers together with ridge

perforations aligned until secure.

45. Apply glue to backside of angled fascia shape

then position and attach to the side walls of under roof,

adjust so that all edges are aligned, and hold in place

until secure. Repeat for second side.

46. To add detail and hide the tab construction,

position and attach the roof overlay strips onto

each level of the shaped roof, centering and

tucking the straight top edge tightly against the inward

perforation where tab cutouts originate.

47. Complete the final details:

A) position and attach the front door wreath; if using

an actual pronged accent brad, it will be necessary

to use a sharp point tool such as this awl to extend

the punch hole through all layers into the hull;

B) position and attach the hanging star to leanto

wall in the same manner.

it with top brads pair in the same manner as wreath

(to keep bottom edge in place, consider using

double-stick tape or other 'temporary' equivalent).

48. To light the house, open back trap door,

insert turned-on LED tea light into cup holder,

then close the trap door. (NOTE that it may

be necessary to use tiny glue dots or small pieces

of double-stick tape at closure circle overlaps

to keep trap door in closed position.)

No comments:

Post a Comment