Wintry

fellow is composed of head and body “spheres”

stabilized and strengthened with

center post anchored onto

a 1/2” tall platform “box” (non-functioning) with

swirls cut out overlay.

Carrot nose tips upward, with other face feature overlays.

Add fringe-bottom neck scarf, buttons (snowflake, round and hearts).

Ensemble measures

approx. 7.125” tall with 4.5” diameter

reel base when completed.

Add a

sized-to-fit miniature hat, if desired,

using the separate design “Top Hat 3D

Mini Candy Cup” design.

ASSEMBLY: 1. Identify and cut the patches:

A body upper dome half shapes

B & I collar rings for build up (3-4; these attach to E

and J to help stabilize center post)

C body lower dome with 'lid' ring with body bottom 'lid'

(NOTE: retain the "waste" center circle to cover post end)

D body lower wedges (7)

E body reinforcement panel (inserts in upper dome)

F head upper dome G head lower dome with 'lid' ring

H head lower dome 'lid' octagon

J head reinforcement panel (inserts in upper dome)

K features: mouth, cheek circles, eye and contrast ovals

L dimensional pyramid nose

M dimensional arm outer shapes (2)

N arm under base shapes (2)

O post P scarf strip (color changed in final model)

Q mittens (left & right) base with thumb and fingers only

(3 ea. to layer for thickness)

R mitten ribbing and contrast underlay (2 ea.)

S heart buttons (3-4 for each of 2 sets for thickness)

T snowflake buttons: snowflake base (2) & button (3-4

for thickness for each of 2 sets)

U mitten overlay "triangles" for dimensional arm sides;

see step 59.

V platform base reinforcement strip

Platform shapes:

A LID decorative overlay with swirls

B LID middle layers for thickness (3)

C LID under layer with boxing slots

D BASE under layer with boxing slots

E BASE middle layers for thickness (3)

F BASE layer - retain 'waste' circle as tabs cover

(see step 55)

G reinforcement collar rings (3 to layer;

will attach to surface of C to stabilize post)

2. Begin by layering and gluing together the several shapes

that will be needed as thickened shapes later in assembly,

so that they can be "curing".

A) layer mitten pair bases, and overlay (finger compartment)

and glue together, taking care to align ALL cut edges

as precisely as possible.

B) Position and attach the finger compartment stack

over the corresponding portion of the left and right base,

aligning edges that should line up precisely.

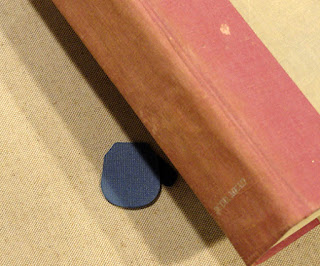

C) for mitten stacks and other layered and glued up stacks,

press under a heavy flat weight such as this old book

until thoroughly dried - at least a few hours or overnight

to avoid warping and curling when using liquid adhesives.

D) Layer mitten ribbing over contrast underlay.

E) Layer and glue up reinforcement collar rings (2),

heart buttons (2) and platform reinforcement ring,

then press under flat weight until dry.

F) Layer and stack the platform BASE middle layers . . .

. . . then layer the underlayer with larger hole,

lining up all cut edges that align precisely,

then press under a large flat weight until thoroughly dry.

G) Layer the platform LID top dec layer and middle layers,

aligning all corresponding cut edges precisely,

then press under large flat weight until thoroughly dry.

H. Prepare the head and body dome reinforcements

by bending edge tabs forward on perforation lines.

I. Position the reinforcement collar stacks onto each

reinforcement panel, lining up the hexagon edges of

the center cutouts precisely (so that post will fit through

without undue resistance). Press flat while the collars

adhesive dries thoroughly.

3. Begin with body upper panels, preparing each half

by bending back along all horizontal perforation lines,

tabs and wedge tabs.

4. Bend the lower segment edges inward to allow

straight edge to overlay adjacent wedge tab to

perforation line, and join seam.

5. Repeat the edge alignment and joining for the second

segment.

6. Continue to join the two-part seams across the first

half dome section, and also across the second.

7. Position the two halves to align and join three

segments for one half-line seam, and then for second

to complete the body upper dome.

8. Prepare the body lower segments by bending back

on all perforation lines.

9. Position and attach lower segment of first two wedges

as with body upper seams. Then . . .

. . . bend, align and join the upper segment of first seam.

10. Continue in the same manner to join the remaining six

wedge two-part seams to form one joined shape.

11. Form the shape into dome shape to position,

align and join the final two-part seam.

12. Prepare the head lower shape by bending back

on all perforation lines.

13. Bend the upper panels back to align straight edge

to overlap adjacent wedge tab to perf line (as for body

portions) to join each of the seams across.

14. Form the dome shape to align the edges for

final seam joining.

15. For each of the dome halves prepared to this point,

bend the upper edge tabs inward at perpendicular angle,

then apply glue to tabs. Bend the attached 'lids' into place,

adjust all edges for best/accurate alignment with

tab perforations, then glue in position.

Use wide openings and finger openings to apply fingertip

pressure to securely attach seams.

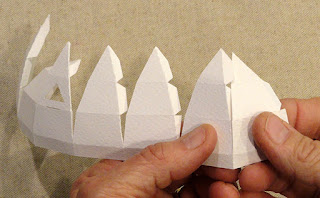

16. Prepare the upper head section by bending back

on all perforations for panels and tabs.

17. Bend the edges back along first seams to

position, align and join seam segments, one by one . . .

. . . as has been done for other dome seams.

NOTE: As joining seams continues, the upper

'opening' will continue to close in and the dome shaping

tension will make final couple of seams a bit

more fiddly.

18. Complete the final seam by aligning and joining

top segment first, compressing top array slightly as

needed to allow seam and tab perf lines to align

accurately. Allow to dry securely, then bend and align

the following three segments and join.

19. TAKE CARE as assembly continues to make sure

that the hexagon post openings are aligned with the "points"

directed front and back - this is marked on several shapes

with the arrow point cutout, as pointed to for

this body upper dome and reinforcement panel.

20. With correct front/back orientation, insert

reinforcement panel into upper body dome . . .

. . . aligning tab panels with octagon dome walls,

then push in and adjust until EACH dome straight edge

aligns exactly along end tab perforation line.

21. Apply adhesive between dome wall along opening

edge and reinforcement surface, then apply pressure

to join completely all around.

22. Prepare to join body domes by bending tabs inward

slightly, applying glue to the extending tabs

all around, then . . .

. . . fit lower body dome over tabs and push together

until dome edges are snugly abutted.

Apply pressure to each edge by reaching fingertip

through end opening, and pressing from outside

until thoroughly attached.

23. Orient the body bottom 'lid' octagon so that

the arrow cutout matches the direction of the interior

reinforcement arrow cutout, then position, align

outer edges with attached octagon edges, and attach.

24. Prepare the dimensional carrot nose by bending

back on all wedge panel and side tab perforations; bend

forward on opening end tabs.

25. Form the nose shape into a pyramid to join

the side seam.

NOTE: it may be helpful to insert something like this

skewer all the way into the tip to provide a "press

against" surface to apply pressure to join the seam.

26. To attach the nose to the head upper form,

first insert the bottom tab into the lower slot . . .

. . . then slide the upper tabs into the triangle opening

so that they rest against the side angled edges.

Push the nose form all the way in, then . . .

. . . bend the tabs each back against the inside head dome

surface and glue securely in place.

27. Position the head reinforcement panel at the upper

head dome open end, aligning each tab with one

facet of dome - with missing tab position at front

(to allow for possible interference with nose tab).

Apply adhesive to inward surfaces of panel tabs, then . . .

. . . slide it inward so that the tabs rest snugly against

inside surfaces of dome walls, adjust to make sure it

is perpendicular to some bottom edge, and apply

pressure to tabs until attached.

NOTE: arrowhead guide will point toward nose panel.

28. Prepare mouth shape by bending back on

the single perf cuts at the one-third positions

in from each end.

Position the mouth so that it "wraps around" front

segment panel just below nose, adjusting it

up/down until perf marks align with panel edges

or transitions to next panels.

29. Place contrast highlight eye panels behind

the black eye shapes and glue in place.

30. Position and attach eyes in positions shown.

Also, test position cheek circles where you wish them

to be attached, over the ridge transition between angled

and side panels of dome, then add bend at that position

so that they can be glued into place snugly hugging the ridges.

31. Prepare to attach head upper and lower domes

by bending the lower dome "tabs" inward, and applying

glue to the outer tab surfaces.

32. Position the halves together so that panel faces

align, then slide the two together until . . .

. . . upper straight edges

align at tab perforation lines.

Reach fingertips inside to apply inner and outer surface

pressure all around until seams are secure.

33. Position the bottom 'lid' at bottom panel,

taking care that the arrow head symbol points

toward the front panel where the nose is attached.

34. Prepare arm shapes by bending back on all perforation

lines (outer shell); bend base forward at perforation line.

35. Join the short side seams on the shell by

overlapping the straight edge to the adjacent tab

to perforation line, and gluing in place.

This is the lower seam, and . . .

. . . and this is the lower seam.

Complete seams on both sides of both shells.

36. Insert the base between the side tabs and position

so that the tab bend is even with the base top edge,

and middle base bend aligns at upper seam.

glue in place, using a blade-like tool such as this

spatula to provide a press-against surface,

for the upper tabs joining, and for the lower tab.

NOTE: push tabs inward so that the base edges rest

in the tab angle bends.

For one side, and then for the other.

38. Begin the platform assemby.

Prepare boxing strip pairs by bending back along

each panel vertical perforation, and along segmented

bottom tabs. Identify the base strips by locating the semi-

circle notch in the side tabs.

39. NOTE that the bottom tabs for each strip segment

is composed of three parts, with center section being

a tab that will be inserted into base slots. Side tabs

will attach to outer base surface.

40. Join pairs of strips for base boxing by overlappingstraight edge across tab to perforation line.

a ring and join second side seam.

the base slotted layer, and insert each segment's center

tab into the corresponding slot.

On base disc backside, bend tab toward center

and glue in place.

Continue inserting center tabs all around,

and gluing to backside in the same manner.

43. Repeat for lid disc and boxing ring.

44. On the inside, apply glue to the side tabs for

each segment around and glue in place to surface.

Complete this step for both base and lid.

45. Position and attach the boxing/disc assemblies

to their corresponding built-up layers discs, taking care

to align all edges, especially matching cut edges

of post hexagon opening.

If possible, use weights to press the layers together

to avoid warping and curling as before with layers build up.

(The lid assembly is shown here.)

46. Position and attach the reinforcement collar

on the underside of the LID assembly, taking care

that hexagon opening edges match up precisely.

Press with weight until dry.

47. Prepare support strut by bending back at vertical

perforation lines, bending tabs forward/outward.

48. Form the strip into a square and join side seam.

49. Position the square inside the base assembly

so that it is centered around the hexagon post opening,

and glue tabs in place.

50. Place lid over base to close and push fully

together to assemble the platform.

51. Prepare the post shape by carefully bending back

along all long vertical perforation lines. Also bend

end tabs forward/outward.

52. Form the shape into a tube to overlap the straight

long edge over the long side tab to perforation line.

NOTE: it is recommended to use the 5/16" dowel as

a wrapping and gluing form. Move fingers back and forth

all along seam to adjust and force into position

as glue grabs to ensure accurate, non-twisting post.

53. Measure the dowel insert. Push original cut end

so that it is even with the post end, with end tabs

bent back and out of the way. Then . . .

. . . mark the edge of the post shape on the dowel.

Remove dowel and cut to marked length.

Apply a little glue into each end of the paper tube,

then insert dowel and push into final position.

54. From platform bottom, insert post assembly up through

hexagon opening (this will be a snug fit), then . . .

. . . push through

to exit through lid hex opening, and . . .

. . . and up so that bottom tabs are flush with disc

inside larger circle cutout. Push back slightly to allow

adhesive to be applied to tops of tabs, then push

fully to attach in place.

55. If possible, use the retained cutout circle fromplatform bottom disc layer to glue in place and cover

the post tabs.

56. Next, insert post top through body assembly bottom

hex opening . . .

. . . through body reinforcement panel opening,

and out through body top hex opening.

Apply adhesive to body bottom 'lid' panel,

then push down fully into position to attach in place.

57. Complete final mitten assembly by placing and

attaching heart button (with twine bow) at center of

each mitten assembly front.

58. Position mitten assembly over the top of arm

"paddle" end shape, tuck end into opening between

arm shell and base, push in fully . . .

. . . so that mitten conceals paddle edges (as shown

here) and glue in place.

59. Position and attach mitten "triangles" ontothe side panel corresponding shapes, on both

left and right sides of arm assemblies.

60. Center and attach ribbing assembly above mitten

on angled panel of arm shell, for both left and right arms

61. Locate snowman's front panel (arrow guide cutout)

then position first arm (left shown here) over side panel,

placing top tab perf line at the ridge between 'lid' panel

and wedge, then glue tab and arm base in place where

they touch body assembly

HINT: use quick-grab glue such as Fabri-Tack.

Repeat to place and attach opposite arm.

62. Prepare neck scarf by wrapping left side over

right, bending at perf cuts near center, and pressing

to flatten that center area. Align brad holes, then

attach with glue applied JUST around holes area.

63. Add some curl to the center portion of the scarf

to assist with "drape" over body dome, insert a mini brad

as scarf tack, then . . .

. . . slip over post, slide down into position . . .

. . . and adjust to position toward one side.

Use a foam square under the brad tack area

to attach in place to body dome.

64. Insert post into head assembly bottom hex opening,

through reinforcement panel, to rest snug against

scarf, and glue in place securely.

65. Position and attach snowflake buttons on front

as shown.

Here is the completed snowman figure on his platform.

I am using a Cricut Maker and it will not load the file. I have attempted to separate the sections and it will not let me do that. Do you have any tips to assist me?

ReplyDeleteWe have had issues with Cricut software using our cut files in the way we are instructed to set them up as contributing designers to Silhouette America. The trouble with Cricut continually modifying their software so that even the work-arounds we find can't be used has been frustrating, and even caused us to take down our own online store, due to the high demand for customer service. Silhouette America claims to have overcome these issues. We're not sure that is true, as you may be able to testify. Since they claim all their store's designs are compatible with Cricut, you will need to inquire for additional customer service through them. So sorry.

DeleteWhere can you purchase the SVG files for this cute little guy?

ReplyDeleteThe Hearthsewn collection of svgs can ONLY be purchased through the Silhouette America's online store Search under "Hearthsewn" under the "Artists" button along the top of the "Designs" page. That design can also be searched by its name in title at beginning of this tutorial.

Delete