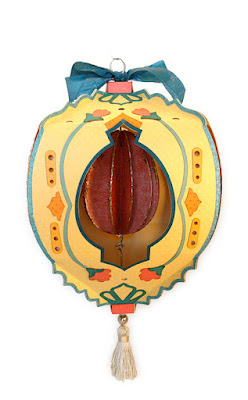

Confection-colored details adorn four outer

panels

of this acorn-shaped vessel which encase the inner lantern hull.

Bracket edge flanges add style at

upper and lower angled edges.

Thread wire or ribbon through center, add beads or

tassel

at bottom end, fashion hanging “eyelet” at top.

Add interior magic by attaching

a dangler of some kind,

such as the “Egg 3D Hollow Ornament”,

“Egg 3D Slice

Form Ornament”, or

two-sided “Cross Scroll Ornament” separate designs.

Enhance holiday decor by hanging from chandelier,

archway, high shelf or other

appropriate location.

Lantern measures approx. 8.25” tall x 4.25” wide when

assembled.

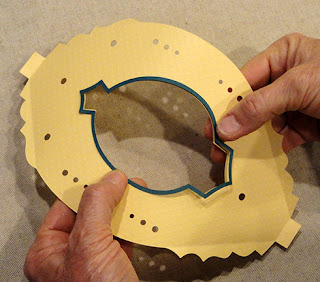

ASSEMBLY: 1. Identify and cut the shapes:

For the inner hull -

A hull two-wall sections (2)

B end collar reinforcement inserts (2)

Not shown: end [repairing] reinforcements (2)

C outer wall panels (4)

D decorations (4 sets), including:

left & right edge trim sections for upper, middle, lower

end brackets for top & bottom

stem rectangles for top & bottom

edge trim for center window opening, crown trim

double-tipped stems, blossoms & sepal overlays

with mid-side flourishes

three-hole "pop tabs" for left and right

all perforation lines except the end collar shapes

side edge and overlap to match up with flange's

perforation line, and glue seam.

Repeat for bottom panels.

overlap straight edge across adjacent tab and join.

two side seams, plus . . .

. . . two upper angled seams and

two lower angled seams, plus . . .

. . . and two upper & lower stems.

6. Bend the side walls of the reinforcement collar insertsforward/up, apply glue to underside/outside of walls,

then insert backside-down into the square

opening. Slide down until . . .

then apply thumb/fingertip pressure at each wall

until firmly in place.

7. Plan and devise a hanging method.

This may include narrow ribbon that can attach an interior

dangling object just at top, or from bottom with a tassel end,

two ends up through lantern interior -- including through

dangler -- then through top to form a hanging loop or

attach to a decorative hook.

NOTE: the ribbon or wire or other center mechanism can be

completed after the outer walls are in place.

However, it may be easier to manipulate and handle

before the walls are in place.

THE PROJECT MODEL USES A WIRE.

A) Form an open end loop/hook at one end of a length

of 16 gauge or equivalent wire which becomes bottom end,

then attach tassel or other bauble, then close loop.

B) Lay wire assembly across top of hull, with end loop

in place where it will stop at bottom stem hole opening.

Measure up wire to approx. position where you desire

bottom of selected dangler to be in finished assembly,

and mark wire.

This image shows the slice form egg ornament as dangler,

held in place to help determine bottom measurement.

C) Form a cork screw "knot" just below the length

that has been marked. This change in the wire is

intended to stop the downward slide of the dangler egg

on the axis of the wire.

D) Insert the wire through bottom of lantern, turning

the wire so that the cork screw turns the punched hole,

while at the same time threading the egg's center tunnel

from bottom to top. Continue inserting the wire through

the top collar platform, then adjust as needed to help

the wire get to the final positioning.

E) At top, carefully use tool(s) to form a top hanging loop

and cutting away excess length.

8. As needed, position and glue in place 1-2 end

"repair" or reinforcement squares at bottom

and/or top collar platform, torqueing to allow the cut

split to open so it can be slipped around wire

or ribbon. Rotate the second (etc.) square so that

the split lands in a different direction from previous.

9. Add some slight back curl to each of the outer wall

shapes: turn panel face down on work surface,

then use a rod tool such as this 3/16" dowel

to press the shape in place while panel is drawn

up from under the tool.

10. Bend angle edge bracket flanges forward (valley)

and end "tabs" forward at top and bottom.

11. Add back curl to long decor shapes that will be

added on front of each panel, so that they will stay

adhered in place.

Then position and glue in place.

Shown in these two frames is the window trim shape.

Add the "crown" accent at the top (narrow end)

where it hugs the top of window trim.

Add the end rectangles and brackets,

"pull tab" shapes where they can "register" at

tri-hole cut out positions.

Prepare the double-tipped stems by attaching

the corresponding small or large blossom overlays,

then the sepals at bottom of blossoms.

Position and attach in space between window trim

and pull tabs, with the center angle centered between

ends of pull tabs.

Position and attach the side "crown" accents centered

and offset on outside of stem center angle.

Finally, add the panel trim shapes at angle edges

upper and lower, and arch side trim shapes.

12. Curve the first completed outer wall panel around

the hull, then position and attach top stem end to stem panel

of inner hull. (Use a quick-grab glue such as Fabri Tack,

to attach ends securely.)

Once one end is securely in place, "wrap" or curve

the panel around the hull to position and attach

the other end in place, gently urging angled perf lines

to match up with the perforation corners of inner hull.

13. Repeat Step 12 to position the next panel,

position and attach first end . . .

. . . then second. As subsequent panels are positioned

and joined in place.

As previously noted, urge the ends into position

to duplicate the end stem panels.

NOTE that the angled bracket flanges

should line up and be glued together as part of the

"adding panel on" process.

14. Continue to add final two side panels in place,

aligning, adjusting, securing and attaching bracket

flanges as done before.

15. Finally, add finishing touches, including

for this wire-center version, a ribbon tied in knot

and bow. (For a ribbon center, consider adding

decorative or painted beads onto the ribbon at stem ends,

or other appropriate decorations of choice.

Here is the completed lantern with slice form

egg dangling inside.