Create this large rooster as a decor

accent

with its many detail: dimensional beak, layer-thick comb & feet,

face mask, body and tail accent overlays,

hex tube legs with 1/4" wooden

dowel inserts for strength and durability.

Assembly is accomplished through

body/head hull box,

legs box insert, attached thigh forms and added on tail.

Measures

approx. 14.5" tall x 9.5" wide x 4" across.

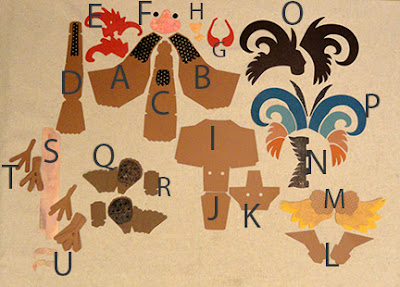

ASSEMBLY: 1. Identify and cut the shapes:

A & B body "hull" side panels with head accents

C front body boxing strip with front neck accent

D top body boxing strip with head top accent strip

E comb build up shapes (6-7) with outer tab shapes

(NOTE: check depth of cut shapes when stacked

to see if 6 or 7, or more, are needed to match

the space between the pair of slots on F;

see step 20)

F face wrap accent with eye contrast under-lay circles

G wattle outer and inner shapes

H beak upper and lower

I body box & leg support main shape J body box back panel

K body box upper shelf

L wing wedge lift platforms left & right

M wing assembly: main wing, upper accent, 4 build up shapes

N inner tail inverted "V" feathers

O tail main and add-on base shapes

P tail feather accent shapes left & right

Q thigh wrap base with outer accents left & right

R thigh wrap add-on panel strip left & right

S leg post "tube" strips (2)

T feet: 2 bottom plus 8 build up for each left & right

U leg spur left & right to join (2 pair)

NOT SHOWN: tail joining tabs (4-6) - see step 29

consider using a flat weight such as this fabric covered

re-purposed free weight bar, or equivalent,

placed on top of the stack and left there for

long enough (sometimes hours) until liquid adhesive

has dried completely. This will help avoid

warping and curling.

Feet: stack left 8 and right 8 and glue together,

taking care to align all outer edges,

and taking particular CARE with the hex opening.

Wings: Stack and attach the 4 main build up shapes

for both left and right wings.

(Model has a special top "face" layer - gold print.)

Also attach the upper wind accent to each stack.

and glue together.

position to align and attach the top front head

segment and the next segment as well.

11. Alternate back to the left body side boxing

attachment to complete upper back and tail seams.

on the face mask, then . . .

. . . bend the tabs outward on the backside

and glue in place.

and glue in place.

at the head as shown, then glue the face mask

surfaces and the back accent onto the body hull

where they touch.

23. Bend top tab on main wattle shape back.

Layer the main wattle shape with top wrap extension

with the shorter backside shape and glue together.

to help it stay in position in front of head.

is visible, then insert it into the back slot on the body hull.

On hull inside, bend the inserted tab toward hull back

and glue in place. (This may require use of a rod tool

to reach inside to apply required pressure.)

On the hull outside surface, glue the platform tab

in position onto boxing.

overlap tail only a scant 1/4" at that lower corner,

and glue all of tail curved edge to body hull

where the two touch.

Repeat for opposite side.

29. Bend the tail connector tabs in half at perforation.

Position and attach the tabs between the broad arc

of top tail as shown, tabs downward and perf fold even

with tail cut edge, and glue in place,

spacing the 6 tabs along the arc evenly

as deemed best to hold the tail edges together.

such as this spatula tip inserted behind the tab seam

to help apply pressure for the joining.

of wing at top and mid lower corresponding

to guide marks, and glue in place.

Repeat for both wings.

with side tabs tucked under the side walls

and glue in place.

Continue to shape the box by bending side walls

up into position to align and glue the front side seams.

bending back along the series of long perforation lines.

the longer end tabs.

surface of platform.

NOTE it will be necessary to trim off the corners

of one or more tab tips so they don't interfere

with the platform walls bending into position.

walls to inside of body box walls.

45. Insert the un-cut dowel into one leg tube

and push in until . . .

adjacent wedge tabs to join bottom seams . . .

should be attached to (Left or Right), then

insert leg post through center, and . . .

. . . slide up fully into position with outer curved top

extending over the hull surface,

front tab extending over the hull front,

inner bottom flange tab seating at body box surface.

appropriate foot stack, then bend tabs back

and glue in place.

A & B body "hull" side panels with head accents

C front body boxing strip with front neck accent

D top body boxing strip with head top accent strip

E comb build up shapes (6-7) with outer tab shapes

(NOTE: check depth of cut shapes when stacked

to see if 6 or 7, or more, are needed to match

the space between the pair of slots on F;

see step 20)

F face wrap accent with eye contrast under-lay circles

G wattle outer and inner shapes

H beak upper and lower

I body box & leg support main shape J body box back panel

K body box upper shelf

L wing wedge lift platforms left & right

M wing assembly: main wing, upper accent, 4 build up shapes

N inner tail inverted "V" feathers

O tail main and add-on base shapes

P tail feather accent shapes left & right

Q thigh wrap base with outer accents left & right

R thigh wrap add-on panel strip left & right

S leg post "tube" strips (2)

T feet: 2 bottom plus 8 build up for each left & right

U leg spur left & right to join (2 pair)

NOT SHOWN: tail joining tabs (4-6) - see step 29

2. Assemble the built-up shapes (comb, feet, wings) so the stacks

can be drying thoroughly before they are needed:

layer comb shapes with all cut edges aligned as

precisely as possible, and glue together.

Add the tabbed outer left and right shapes

on top of the stack, matching edges that should align,

and glue together.

For stacked or built-up shape components,consider using a flat weight such as this fabric covered

re-purposed free weight bar, or equivalent,

placed on top of the stack and left there for

long enough (sometimes hours) until liquid adhesive

has dried completely. This will help avoid

warping and curling.

Feet: stack left 8 and right 8 and glue together,

taking care to align all outer edges,

and taking particular CARE with the hex opening.

Also glue together the pair of left and right shapes

without the hex opening (bottom foot layer)

Eventually, attach the bottom 2-shape stacks onto

bottom of stacked left or right foot shapes.

for both left and right wings.

(Model has a special top "face" layer - gold print.)

Also attach the upper wind accent to each stack.

3. Position and attach the head accent shapes

onto corresponding left or right body side panel shapes,

with offset margin on sides and upper edge as shown.

4. Prepare the front and upper body boxing strips

by bending back side flange tabs, also bending

on cross perforations as MOUNTAIN or VALLEY

folds to match the contour of the body shapes

(shown here with M for mountain or

V for valley folds).

5. Begin to attach the upper boxing strip to the right

side body shape by lining up the longest edge

of back neck area with the second from top boxing flange.

Overlap side body straight edge over boxing segment

to perforation line, adjust top to bottom

for more perfect alignment, then glue in place.

6. Bend the next up segment and edge togetherand glue together.

7. Position top tab flange of other boxing strip

under the top straight edge of upper boxing strip,

adjust for side to side alignment, then glue together.

8. Continue to bend the boxing front strip intoposition to align and attach the top front head

segment and the next segment as well.

9. In order to reach into the head area

to make adjustments and to apply pressure to

seam area, pause the attachment of right side body

panel flanges to boxing strips.

Position and attach the opposite (left) side body

panel by repeating the positioning and attachment

as shown in steps 5, 6 and 8.

10. Return to the right body side to position and

attach the boxing segments across the rooster

back body . . .

. . . and end tail section.11. Alternate back to the left body side boxing

attachment to complete upper back and tail seams.

12. Return to the right front to position and attach

the remaining boxing segments, then

complete the same seams for the left body.

All of boxing to side body panels should be completed.

13. Prepare the inner tail shape by bending back

at mid center short perf line, and bend tabs outward.

Position and insert tabs into body tail end slots.

On inside of body cavity, bend the tabs outward

and glue in place.

14. Bend the front neck accent forward slightly

at the middle perforation, then position, centered,

at second-down front "neck" bend and glue in place.

15. Prepare the face "mask" shape by bending

back on all perforation lines.

Position and glue the contrast eye circles

behind the shape so that the contrast circles

show thru the cut openings.

16. Prepare the upper and lower beak shapes

by bending back on main perf lines,

bending the tabs on upper beak forward.

17. Prepare the lower beak by bending it into

a dimensional triangle shape to overlap the straight

inside side edge to overlap the tab opposite

and glue seam.

18. Insert the tabs of upper beak into the slotson the face mask, then . . .

. . . bend the tabs outward on the backside

and glue in place.

19. Position the lower beak centered beneath

the upper beak, tucked up to be snug next to

upper beak lower corners, but NOT inside it.

Glue in place.

20. Insert the forward tabs of comb build up

into the top panel slots, then . . .

. . . bend the tabs outward on the backsideand glue in place.

21. Complete similar step with the top head

accent shape, inserting tabs into slots,

bending tabs outward and gluing in place.

22. Position the face/beak/comb assembly in positionat the head as shown, then glue the face mask

surfaces and the back accent onto the body hull

where they touch.

23. Bend top tab on main wattle shape back.

Layer the main wattle shape with top wrap extension

with the shorter backside shape and glue together.

24. Position the bend of the wattle assembly

at the top of the beak, with wattle hanging

down the rooster's right side, and glue

touching surfaces (wattle to upper beak) together.

Also give the wattle a slight bend near the lower beakto help it stay in position in front of head.

25. Prepare the two tail sections by bending back

on all perforation lines of each.

Position the two together at an angle as shown

to overlap straight edge of add-on (shown right)

section over angled edge tab, and glue together.

26. Position and attach the various accent shapes

to the tail on one side (also add slight bend to the two

accents that include perforation lines) with the top

plume necessarily overlapping the other plume,

then adjust for opposite top overlap to enable

opposite side accents to be attached.

27. Invert the tail so that the bottom pop-out tabis visible, then insert it into the back slot on the body hull.

On hull inside, bend the inserted tab toward hull back

and glue in place. (This may require use of a rod tool

to reach inside to apply required pressure.)

On the hull outside surface, glue the platform tab

in position onto boxing.

28. Locate the back bottom corner of the body hull

as the key place in positioning bottom of tail, then . . .

. . . "swing" the tail downward into position tooverlap tail only a scant 1/4" at that lower corner,

and glue all of tail curved edge to body hull

where the two touch.

Repeat for opposite side.

29. Bend the tail connector tabs in half at perforation.

Position and attach the tabs between the broad arc

of top tail as shown, tabs downward and perf fold even

with tail cut edge, and glue in place,

spacing the 6 tabs along the arc evenly

as deemed best to hold the tail edges together.

30. Prepare the wing wedge platform shapes

by bending back on all perforation lines

and tabs.

31. Bend side walls back so that the ends come

together in narrow angle. Tuck tab inward

and glue in place to opposite wall.

NOTE that it will be helpful to use a thin blade toolsuch as this spatula tip inserted behind the tab seam

to help apply pressure for the joining.

32. Bend the point tabs inward,

bend the back panel to close the wedge box

and glue the back underside to the tabs.

(Complete left and right wedge platforms.)

34. Identify the perf mark guide lines on

wing stack underside, then . . .

. . . position the matching platform box to match

guide marks, and glue in place.

NOTE that the platform wedge should be

completely behind the wing stack.

35. Locate the curved wing perforation guide marks

on the side body, then . . .

. . . position the wing as shown with the curved edgesof wing at top and mid lower corresponding

to guide marks, and glue in place.

Repeat for both wings.

36. Prepare the body box by bending back

on all perforation lines for main shape and

for added back wall.

37. Position the back wall lower tab under

the bottom wall edge as shown, adjust,

then glue edge and tab together.

38. Bend the bottom back into positionwith side tabs tucked under the side walls

and glue in place.

Continue to shape the box by bending side walls

up into position to align and glue the front side seams.

39. Prepare the platform insert by bending

back and side walls forward.

40. Prepare the leg post shapes by carefullybending back along the series of long perforation lines.

41. Form the leg posts each into a tube.

Wrap around the 1/4" wooden dowel that will be

cut to size later in assembly, but now will act

as a glue-up form.

Overlap the long side straight edge over

the opposite long flange tab, force the tube tightly

around dowel until edge matches up with opposite

tab perf, and glue the seam, working finger pressure

continually along the length of the seam to ensure

the tight wrap is maintained, and the seam is secure.

42. Identify the TOP of the leg post which hasthe longer end tabs.

Insert the post top into the hex leg opening on

bottom of body box above top edges.

Repeat for second post.

43. Position the platform structure above

body box (orient the fronts marked with 'F'

in same direction), then . . .

. . . insert posts through hex holes in same manner.

Bend top tabs back and attach to inside basesurface of platform.

NOTE it will be necessary to trim off the corners

of one or more tab tips so they don't interfere

with the platform walls bending into position.

44. Push the leg posts down with platform

attached so that it inserts into the top of

body box, and continue sliding platform into

position until . . .

. . . tops of walls match up. Glue platformwalls to inside of body box walls.

45. Insert the un-cut dowel into one leg tube

and push in until . . .

. . . top of dowel reaches but DOES NOT extend

above the platform/side wall edge.

Hold dowel securely in this position until . . .

. . . the length can be marked as shown

with this mechanical pencil, at leg post length

WITH TABS BENT BACK OUT OF THE WAY.

Remove the dowel and cut to size for first leg,

then repeat the inserting, measuring/marking,

and cutting of dowel for second leg.

46. Apply glue strategically to inside of post tube,

then insert dowel for final time and

push fully into position as it was measured.

Apply glue to exposed dowel edges

to attach each to the body box side wall.

47. Insert the box (orient F toward rooster front)

inside the rooster hull, and push in fully -

this may take a little maneuvering to get the upper

edges to align correctly and seat together fully.

Bottom body box edges should be fully inside

of hull bottom tabs. Glue body box in place.

Bend hull tabs inward and glue in place

to bottom of body box.

48. Identify the thigh main and add-on strip shapes

for left and right thigh box structure.

NOTE that a tiny 'L' will identify the shapes

that will create the left structure.

Since these symbols will be hidden when the need

to identify left and right arises, transfer the 'L'

by hand with pen or pencil onto

the upper backside of shape.

Prepare the main and add-on strips by bending

back on all perforation lines, except the upper edge

tabs which are bent forward.

49. Position the side flange tab of add-on strip

next to the corresponding side straight edge

of main shape, overlap and join the seam.

50. Bend the shape so that straight edges overlapadjacent wedge tabs to join bottom seams . . .

. . . around bottom of structure until . . .

. . . each wedge seam is joined, and . . .

. . . box is formed into a tube to complete

the final back inner side seam and lower segment.

51. Prepare the thigh left and right accent overlay

shapes by bending back slightly on the middle

perforation line, also bending the "feather" tab

cutouts outward sightly.

Position and attach the appropriate accent over

the main face of the thigh box with

perforation lines lined up.

52. Determine which side each thigh structureshould be attached to (Left or Right), then

insert leg post through center, and . . .

. . . slide up fully into position with outer curved top

extending over the hull surface,

front tab extending over the hull front,

inner bottom flange tab seating at body box surface.

Glue all touching surfaces together.

NOTE if may be helpful to use a tool to help

apply pressure to front tab and inner flanges.

Repeat for second thigh and leg.

53. Prepare to attach the feet to legs by

orienting the feet stacks at leg ends so that

"toes" angle away from center as shown.

Insert leg post bottom end through hex opening ofappropriate foot stack, then bend tabs back

and glue in place.

54. Position the matching bottom (2-layer) short stack

to align with attached foot, and join.

Consider using flat weights placed over front

and back toes of feet to help them attach securely

and avoid warping and curling.

Repeat for second foot.

56. Prepare the spur paired shapes by bending

inner perf line as "valley" fold, outer perf line

as "mountain" fold as shown for each of paired set.

Position the pairs back to back to align and attach

the hooked portions ONLY; tabs should remain free.

This is how the completed spur structure appears.

57. Position the spur at the back of the leg

approx. 3/4" or so above foot, with tabs

placed to wrap around leg post, and glue in place.

Repeat for both legs and spurs.

Rooster assembly is complete.

I really love this rooster! Will purchase all your chicken designs as soon as the tutorials are up and running!

ReplyDeleteThank you so much for this clear tutorial. Your work is great!!! BIG compliments!

ReplyDeleteWorking to get the text together with the images. Sorry this is taking so long. Crazy week.

ReplyDeleteIt's a really lovely roster! Thank you for the tutorial.roberta

ReplyDelete