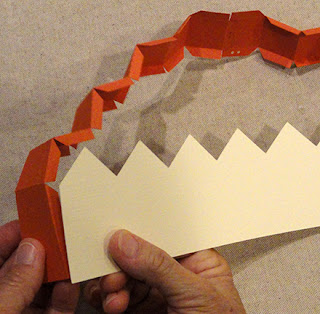

Sawtooth-topped trio of walls form short outer and tall center

narrow-depth boxes that are joined to create two-level platform

where cat-fronted 3D star box can move

to count down days until Halloween.

Design includes vinyl word art to

help explain

the decoration’s function: “Meow ... many days ‘til Halloween?”

to be centered on the exposed tall walls using built-in

positioning guides. Stencil-style cut-out numbers 1 thru 30

show thru across pairs of panels on box fronts and backs,

arranged so that star/cat marker begins at #30 and moves left

across lower box then right across top box for . . .

. . . the first half of October. Then it jumps to reverse

side

and #15 to continue moving until it gets to #1

on the day before

Halloween. Hidden 1/4” ceramic magnets

are attached inside star box “legs” to

gently connect

where small zinc washers are attached behind saw tooth top,

assisting cat marker counter to stay in place.

Checker panels "squares" are extensions downward

or upward from contrast number "underlays".

Joined saw tooth boxes ensemble

measures

approx. 11.7” across x 7.75” tall x 3” deep.

3D Star measures approx.

2.5” tall x 2.5” wide x 1” deep.

2D Cat decoration is approx. 4” tall.

(Requires

approx. nine 12x12 sheets of orange for hull components.)

ASSEMBLY: 1. Identify and cut the shapes for

SHORT BOXES (2 sets):

A box sawtooth front (checker background) & F back

B black upper and lower contrast & checker underlays

C number overlay (back - 8-15; front - 23-30)

D lower "accent" strip (matched to hull)

E boxing strips

G "base" insert hull H interior strut reinforcement strips

I insert end boxing strips (2)

J & R hull front and back panels

K & S contrast & checker extensions

L number panel overlays (back 1-7; front 16-22)

M checker light strip (2)

N - Q boxing strips T side lower accents

V front hull & W back hull

X side boxing strips (2)

A star boxing strip B star front C star back

D front star decoration contrast

E front star decoration panel

F cat body base silhouette (to assemble on)

G tail overlay

H body (NOTE this shape should NOT have tail)

I face J tongue inlay K muzzle overlay

L nose and whiskers M eyes inlays

2. Obtain the magnetic components for this project:

2 - .5" diam ceramic magnet discs for star "legs"

46 - metal flat washers approx. .5" diam.

VINYL APPLICATION

3. Follow standard vinyl transfer process to prepare

vinyl marquee word art panels (cut, weed, attach to

transfer tape, etc.), including the center hashmark

and corner registration marks. TIP: remove a narrow

margin of backing paper only so that registration marks

can be positioned and "stuck" to the card stock paper

front panel while maintaining some adjustability.

4. Locate the center mark and side-ward dash line guide

marks on the card stock panel, then align the vinyl centers

while at the same time positioning the upper EDGE of

corner cutout at or just below the side dash mark.

Secure this positioning, remove remaining backing,

and attach vinyl in place.

Use a tool to carefully remove the vinyl positioning guides.

Set panels aside until assemble continues in Step 20.

SHORT BOX ASSEMBLY - make 2

5. Identify the short box boxing strips with center edges

that include the double circle symbols. Then . . .

. . . bend back the side edge tabs. Also bend and

crease the cross perforation lines to imitate the outer

edge shape of the front/back panels.

NOTE that the edge tabs across top are shaped to

include deep angles where the segment edges fall

at the sawtooth points, and slit cuts at the valleys.

6. Join the two strips at the center seam by overlapping

the straight end edge across the opposite tab to

perf line, adjusting top to bottom, then gluing in place.

ALTERNATE ASSEMBLY ORDER NOTE:

After tutorial images were shot, it was determined that

the number panel and checker strip decorations could also

be attached to the front panel prior to attaching the boxing.

If you prefer to follow that order, skip forward to complete

Steps 11-12, then return to continue with Step 7, here.

7. Begin to attach boxing at one end, aligning the side long

segment along side panel edge, overlapping panel across

boxing flange, adjusting for precise top and bottom alignment,

then glue the segment in place.

9. Continue in the same fashion to position and attach

sawtooth segments across top of front panel.

NOTE that it may prove helpful to position and attach

pairs of segments in one step, such as the left and

right segments shown here that are adjacent across

the "valley" bend.

Also, as segment seams are completed,

it may be helpful to turn the work face down to apply

pressure along the seam from backside.

10. Complete the boxing strip attachment at the second

end, positioning and attaching final segments as shown.

11. Prepare the number overlay and checker decoration

assemblies by layering the selected number sawtooth

overlay on top of the upper checker underlay,

with "accent" strip on top of lower checker underlay,

adjusting so that corresponding edges align accurately,

then attaching in place.

NOTE that - as always - any layers that are thoroughly

glued together using liquid adhesive should be pressed

flat with heavy flat object during the drying process,

until thoroughly dried. This prevents or minimized warping

or curling.

12. Position and attach the top assembly . . .

. . . and lower assembly to the front of

the partially-assembled box, matching corresponding

cut edges as precisely as possible.

Reverse the assembly face down on flat work surface

and apply ample fingertip pressure to backside to ensure

complete attachment in place.

13. Before attaching back panel, position and glue

in place with sturdy quick-grab adhesive such as

the Fabri-Tack glue shown here one metal washer

onto the center of each sawtooth boxing segment.

(This positioning will eventually align with magnets that will

be attached to the inside of 3D star marker "legs".)

14. Position the back panel in place to match up

with the boxing edges, then . . .

. . . work along the edges to attach fully and

accurately in place.

SHORT BOX INSERT

15. Bend back the insert hull sides at long perforation

lines. Also bend back the end boxing tabs.

Position each end between the wall and bottom ends . . .

. . . and attach in place at three edges. Repeat

for opposite end.

16. Prepare the reinforcement strut strips by bending

tabs forward, and cross perf lines in alternating

zigzag fashion. Position and attach straight end

of right-position strip to cross tab of left strip.

17. Compress the accordion folds, apply glue to

the underside of tabs, then insert into the base box . . .

. . . and adjust so that it spreads nearly end to end

. . . and adjust so that it spreads nearly end to end

with outward corners at least .25" inside box edge.

Apply pressure to attach tabs to inside of box.

18. Complete final assembly of short box by tucking

the insert into the bottom opening of sawtooth "lid" . . .

. . . and carefully pushing insert in until approx. .25"

remains visible. Apply glue to this margin, then

continue to push in until bottom edges align flush.

(NOTE this is a snug fit by design.)

Apply fingertip pressure or brace between books

or blocks, etc., to ensure that walls completely

attach in place all around.

TALL BOX ASSEMBLY

19. Assemble the 2 number panels with checker strip

decoration in similar manner to Short Box decoration,

except that the contrast narrow strip is attached

behind the checker "teeth" extensions as shown here.

the tall wall/vinyl panel assembly with corresponding

edges aligned as precisely as possible, and attach, press.

21. Identify the 4 boxing strips as they will be joined

in order by noting that small symbols are cut into

the end tab and the nearest-to-end side tab where

they will connect.

(NOTE the next few assembly steps will show the front

panel without the number/checker decoration panels

in place, but it is recommended that they should be.)

corresponding panel edges, then align and join

align, adjust and attach each progressing segment.

As tabs and flanges are attached, reverse the assembly

As tabs and flanges are attached, reverse the assembly

face down on flat work surface to apply fingertip pressure

along the edges to ensure complete attachment.

24. Position and join seams of second boxing strip

then continue to position and attach in place around, as well as . . .

sawtooth segment across top of assembly in manner

align edges with boxing tab bends, adjust and attach

in place. NOTE that it may be helpful to begin at center top

and work across one half first, then second half, then

work downward to complete sides attachment.

TALL BOX INSERT

27. Bend back the panel with bottom and long flange,

then align and join the seam.

28. Bend back the side and bottom flange of side boxing

panels, then position at main hull ends . . .

. . . and join in place.

29. Prepare the strut reinforcement strips by bending

and joining end to end into two sets, as with strut strips

for short boxes, Step 16.

In case there is any confusion about which strut strips

are for the Tall box, these have a 'T' symbol cut in.

30. Repeat similar process for compressing the first

joined strip as for short box in Step 17, inserting

it inside the base insert box.

Push the first strip down inside to lie across the bottom

half, spread and adjust (use the finger access cut out holes),

then apply pressure to secure the adhesive-applied tabs.

31. Repeat the process for the second strip which will

lie across the top half. (Strut reinforcements supply

structure so the base will not collapse flat.)

32. Place the insert inside the tall box and . . .

. . . push into place (this is a snug fit) until a narrow

margin remains. Apply adhesive to the margin of front

and back panels only, then . . .

. . . push in completely

until bottom edges of hull and insert are flush.

Apply fingertip pressure (or set up with braced flat

objects to help hold walls pressed together) until dry.

33. Bend the bottom end tabs to prepare to insert

into position, add adhesive to all tabs, then push

into place to attach tab surfaces to adjoining walls.

BOX-TO-BOX ASSEMBLY

34. Apply quick grab adhesive to backside of front

short box, then position onto front of tall box

at lower edge and attach in place.

Sides and bottom edges should align.

(Make sure the number panels correspond as designed -

these number ranges are FRONT.)

Repeat for the back side and second short box.

35. Position and attach side accent, with narrowoffset margin at side, lower and upper edges (within

STAR BOX AND CAT

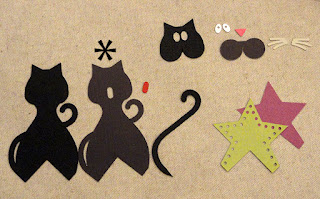

36. Prepare to assemble the cat figure so that it can

be pressed and thoroughly dried.

NOTE that the cat body shape highlighted by '*'

in this layout should NOT include the tail silhouette.

A. Add tail to silhouette base shape.

B. Position and attach body on top of silhouette

with corresponding outer edges aligned precisely.

C. Position and attach tongue in body cutout.

D. Add muzzle to head lower edge.

E. Add nose to upper center muzzle.

F. Add star accent front on top of contrast accent.

G. Add head to assembly.

H. Add eyes into sockets, whiskers to muzzle.

I. Position and attach star assembly at lower center

where the "legs" edges align.

37. Press the body/star assembly under a heavy flat weight

until thoroughly dried.

38. Identify the star box front by locating the 'F'.

Prepare the boxing strip by bending to match

the star outer edge shape. NOTE that the tab cut away

or dash line cuts will follow same patterns as for

sawtooth box tops as described in Step 5.

39. Begin at the center of the strip, and at center top

star point to line up, adjust and join the first edge

to boxing.

40. Bend the boxing strip to align, adjust and

attach the segment tabs down the remainder of

the first half side . . .

. . . noting that it may be helpful to reverse the assemblyface down on work surface to apply fingertip pressure

along edges and as far up into points as possible.

Complete the first half, with the strip seam tab at end.

Complete the first half, with the strip seam tab at end.

41. Return to center top to repeat the process to

position and attach the second boxing half.

When the final segments remain, it will be helpful

to apply glue to these, as well as opposite end tab,

then swing two segments into position, align

and join all including seam.

the star box at the center of the 'leg' segments

at the bottom, then position and attach one .5"

ceramic magnet disc . . .

. . . as can be seen here in place.

44. Position the cat decoration over the front. . . as can be seen here in place.

43. Re-bend the back edge tabs to perpendicular,

then add glue to the tab faces, position and attach

the back star. Work around the edge to use finger

pressure to adjust and hold points in corrected

positions until all are secure and neatly in place.

of the star box, with lower straight edges that

correspond aligned as precisely as possible,

and securely attach in place.

45. To work the count down, place the cat/star

magnet over the sawtooth crest at #30 on

October 1st - this will indicate that there are

"30 more days" 'til Halloween. Each day, the cat

is moved along the bottom ridges, then back

toward right along top on same side. On October 15th,

the box is reversed and the process imitated for

the remainder of October days, until cat/star is above

#1 on October 30!

Magnets in star legs will gently "attach" to the washers

placed in each of the sawtooth crest segments

so that it will stay in place.

Enjoy your "Meow-y" October!

I have bought dozens of your files on Silhouette Design Space and selected the SVG files as I only have a cricut. I bought the three sets of foldable quilt cards and they do not come out as A2 cards, they come as all one color and the score lines do not attach in the right place. I have checked other files from you and so far all of the SVG ones I purchased do not work out. I cannot find a way to contact you on the SD sight, so I am trying here.

ReplyDeleteI am so sorry - this is a problem that has been ongoing for about 8 years now. The way Silhouette America has us prepare and submit (then they approve) our cut files simply does not seem to be compatible with Cricut programs. When we had our own online store we spent hours and hours trying to work around this issue, and if we found something that worked, it seemed like Cricut soon "fixed" their software to make it not work any more. Frankly, it is what put us out of business. I don't know the Cricut system, so I can't even offer to send you specially-prepared files, not to mention that the earnings I get from each Silhouette being just pennies which doesn't make business sense for me to fix a problem that is really the responsibility of Silhouette America. When they first informed us that they would be making the svg files available online for purchase by other system users, we warned them of our experience, but they proceeded thinking they were addressing it. I can only advise you to contact them. Wish I had a better answer for you.

DeleteI love this project. Do you by chance have one that could work as a monthly calendar...like 31 days and a 7 pointed star?

ReplyDeleteI want to be notified, so I'm replying to myself :-D

DeleteInteresting idea but I'm afraid I cannot visualize what you are thinking of. If you want to elaborate, I can put it in the design "stew pot" and think about it sometime.

Delete