many

holidays with customized coloration.

She is composed of outer and inner reinforcing hull.

Skinny arm tubes enclose 1/4”

wooden dowels

cut to size below threading holes,

with fold-over simple hands

that attach at bottom tab extensions.

Complex oval shaped head has multiple

wedge seams

and tabs, and fits onto the top of a hex tube-wrapped

1/4” wooden

dowel inserted through assembled

body hull and attached at bottom.

Arms are

attached with ribbon or twine and bead joints.

Brocade wings

have built-up layers on front,

aligned with small punch hole pair on back .

Tiny heart button and “halo” wreath layers add details.

Measures approx. 7.75” tall x 4.5” wide (wingspan)

x 2.35” deep

(at base) when assembled.

ASSEMBLY: 1. Identify and cut the shapes:

A main body hull B lower body hull

C post collar build up (7-8)

D bottom hull cover

E bottom hull top opening reinforcement

F post strip G arm tubes (1 l, 1 r)

H hand shapes

I body center accent overlay

J body side accent overlays (2)

K head front (face) L head back

M eye contrast underlay N opt. cheek stencil

O heart button build up (8)

P wing base and build up overlays (see next screen)

Here are the wing shapes:

(NOTE that, except for main base,

the shapes are cut as left and right sets,

with 2 layers of each being cut.

(Petal interior circles and teardrop should be

retained from the petal cut, so that each will be

stacked in sets of 4 shapes.)

2. Layer and glue together the shapes that need

to be prepared so that they can be drying/setting

while other construction proceeds.

A. Stack and glue the post collar shapes,

taking care to align all cut edges as precisely as possible

(for this shape and all others), particularly at

the inside opening where post will need to fit.

NOTE: for glued-up shapes, it will be helpful

when using liquid glue to press them under a flat

heavy weight of some kind, such as the fabric-covered

re-purposed flat weight shown here.

It may take several hours for shapes to dry completely.

Pressing the shape stacks will help keep the flat,

avoiding warping and curling.

B. Layer and stack the heart button shapes.

3. Layer and stack the left and right wing shapes:

A. the main base (double-wide) shapes

and the left and right wing bases

B. leaf base and overlays

contour left and right, middle circles (4 ea.)

and tear drop (4)

D. the three swooshes

4. Assemble the wings (complete both left & right halves):

A. petal base with overlay shapes

B. petal tips with outer edges even onpetal base

C. contours onto each side of petal assembly

(upper portion of outer edges aligned)

D. leaf shape onto section bases with matched

edges offset very slightly

E. petal assembly onto section base

F. swooshes large to small toward edge,

aligning large rounded edge offset at lower portion . . .

. . . and narrow tips at scallop edges at top

G. insert circle and teardrop stacks into recesses

5. Position and attach the half assemblies onto

the double-wide wing base, with narrow offset

at edges.

6. Prepare the post wrap shape by carefully

bending back on all the long perforation lines.

7. Form the post wrap into a tube. To assist gluingof seam, insert the uncut 1/4" wooden dowel inside

the tube, then apply glue to backside of flange,

wrap straight edge over flange and force edge

to match up with the first perforation line, and

apply pressure all along the seam until it is

accurately attached and secure.

8. Push dowel in to be even with top edge,

mark bottom edge with pencil, then remove

and cut dowel to size with small hand saw tool.

9. Push dowel out one edge slightly, apply glue

to exposed dowel and to the inside of empty post tube

at opposite end, then re-position to attach tube to dowel.

10. Prepare the main hull shape by bending backon all segment perforation lines and side flange,

top tabs and top "lid". Also push back the top center

hex opening, then . . .

. . . use the completed post unit to prepare top

post opening of the main hull "lid" by rotating hex tube

to match the opening dash line, then pushing through

to bend the wedge tabs inward.

11. Identify the center segment (wide with NO punches),

then . . .

. . . position and attach the offset accent panels

over corresponding wide segments.

NOTE: if you prefer to have a back accent also,

cut a second "center front" panel, position and

attach over the "back" panel, then use a piercing

tool such as an awl to poke through where wing

alignment hole punches are on the hull shape.

12. Form the hull into a tube to bring the straight

back segment edge to overlap the opposite flange

to perforation line, and glue the side seam.

NOTE it may be helpful to insert a rigid tool

into hull behind the seam to provide a press-against

surface to help secure the seam across the center.

13. Bend the top tabs inward . . .

. . . then bend the top "lid" into position

to align cut edges as tab perforation lines,

and glue in place.

14. Prepare the lower hull shape by bending back

on all segments and flange perforation lines,

bottom base and tab lines.

15. Position the collar stack on the inside of

the base shape with hexagon openings

aligned as precisely as possible, and glue in place.

16. On the outside, position (centered) and glue

the bottom cover in place.

17. Form the lower hull into a tube to join the side seam.

18. Bend the bottom tabs inward, bend the bottom

panel into position, align and attach edges at

perforation edges.

19. Prepare the top reinforcement shape by

bending the edge flanges forward.

Insert the reinforcement into the opening, then . . .

. . . align first long tab edge at correspondinghull top long edge and glue in place until secure.

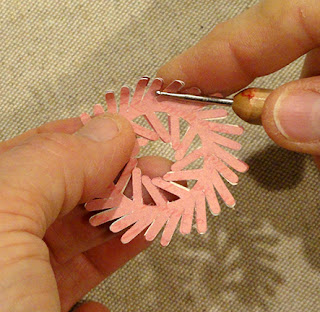

Use a tool (such as this weeder hook) to pull

the reinforcement shape into position

(this is a snug fit) so that all other edges align

and can be glued to hull top edges.

20. Apply glue along inner hull lower wall edge,

then insert lower hull into the bottom opening

of the upper hull, and slide the two together

until bottoms are aligned as closely as possible.

21. Prepare the left and right arm tube shapes

by bending back on the long perforation lines

(similar to post tube) and also bend the upper

tabs and hex panel inward, and lower tabs and

hand* extensions inward (*hand extension base

perforation is bent back, second perf line is

bent forward).

the 1/4" uncut dowel to assist with aligning

side straight edge and side flange perf line

and gluing the seam.

23. Move the top of dowel down to align end

with top tabs and hex panel, then bend

tabs inward . . .

. . . bend "cap" hex into position and glue in place.

24. Cut two arm dowel insert pieces at 2.125" each

(NOTE that dowel will not fill the arm tube

beyond the ribbon-joint hole punch.

25. Insert dowel into bottom of arm tube

and push inward until end is even with

bottom/hand base tab perforations.

Glue dowel in place.

Bend tabs inward . . .

. . . bend hands toward center as shown,

glue hand base segments to top of dowel,

and hand main portions back to back

to each other.

26. Prepare hand overlays bybending back on center perforation line.

Apply glue to hand underside,

then wrap around hand extension,

adjust and glue in place.

27. Prepare ribbon or twine joint with bead ends

by threading a needle that will fit through selected beads

with a double length.

A. thread needle through bead and tie end knot and bow.

B. thread needle through first arm hole punches

(NOTE hand straight edge is front edge).

C. thread needle through hull side panel hole punches.

E. thread through final bead, tie knot and bow,

and trim excess ribbon or twine.

28. Prepare the head shapes by bending back

on all perforation lines for panels, wedge and edge

tabs, etc.

29. Position and attach the eye contrast shape

behind the eye punches of face panel.

30. Bend head front panel segments to overlap

and align perforation and straight seam edges:

A. first top side seam

B. second top side seamC. mid side two-part seam

E. bottom side seam

F. bottom mid side two-part seam

(Complete second side in same manner.)

31. Bend side panels of head partition back, then . . .

. . . apply glue to the lower wedge tabs andto other side tabs.

Bend tabs inward then bend partition into place,

tucking tabs inside head edges, and glue in place.

(Refer to step 33 to see partition panel in final position.)

32. Prepare the back head in similar manner

by completing the upper . . .

. . . and lower side seams.33. Insert the bottom tab with hex opening

fully into the bottom slot of front head assembly

and glue in place.

34. Insert side and top tabs into corresponding

slots, push in fully, and glue in place.

If possible, at the same time, apply glue along

inner edge of head back so that these will

join to front edge edges.

35. To apply cheek rouging, bend the check stencil

shape back on perf lines, then position with bottom edge

at face panel bottom edge, secure in place with temp tape,

then apply distressing ink or stencil paint, etc.

Remove and discard stencil.

36. Assemble the angel figure by applying glueto the post end, then inserting

it into hull through top hex opening,

working into position in front of or behind the arm

joint ribbon/twine, through interior reinforcement

hex opening, then . . .

. . . down to bottom to seat the end into the collar

hex recess at inner hole bottom panel,

applying pressure to sense when post fits in properly.

37. Apply glue to back panel face of exposed post,

then inserting end into head bottom opening,

and sliding head fully into position, then applying

pressure so that back of post attaches to

interior partition.

38. Position and attach wings so that punch holes

align with corresponding holes of hull back panel . . .

. . . then apply pressure until securely attached.Insert and glue in place mini brads through

punch holes (or studs to cover holes, etc.).

39. Use a narrow tool such as this fine stylus tip

to add upward or downward curl to halo wreath

shapes, outer and inner twigs.

NOTE: non-card stock weight will work best for halo

shapes. If paper with color on face and back is not

available, consider cutting duplicate mirror shapes

and gluing the two back to back before beginning assembly.

40. Stack the two halo wreaths, rotating slightlyso that twigs offset, then glue together at 'ring".

41. Position and attach halo over top of head,

tipping back slightly as desired (see final photo).

(Model project has tiny artificial buds as decoration.)

42. Thread twine through heart button holes

and tie knot and bow.

Position and securely attach on front panel.

Here is finished project.

No comments:

Post a Comment