Build

dimensional uppercase letter B composed of

LID and BASE, each with an interior

opening form

that makes fitting the curved boxing sections along those

openings.

Then fit the lid and base snugly together.

Decorate the front of the

paired contrast ‘B’ overlay

with honeycomb accent layers.

Designed specifically

as the beginning letter of

the 3D letter boxes that spell out BLOOM.

Measures

approx. 6” tall x 3” wide x 1.75” deep assembled.

ASSEMBLY: 1. Identify and cut the shapes:

A 'B' Letter box main front panel

B-D LID boxing panels

E LID interior openings assembly insert

F & G LID interior openings boxing

H 'B' accent overlay and honeycomb overlay

(NOT SHOWN: optional wire attachment tab

for Bee 3D form attachment on lead boxing edge)

I 'B' Letter box BASE back panel with optional trap door

J-L BASE boxing strips

M LID interior openings assembly insert

N & O LID interior openings boxing

P optional support strut to stabilize 3D Bee wire

or tabs that help identify which strips ends join

and where the seams fall as they join to LID or BASE

main 'B' shapes.

Refer to this illustration of the B LID main shape (top)

and the B BASE main shape, and their associated

interior opening insert shapes to identify where

the boxing strips will be joined, according to symbols.

(NOTE: "T" in the insert shapes refers to "top".

3. Identify the boxing strip edges that will form

curves by locating the multiple wedge tabs.

Use a rod tool such as this rounded pencil shaft,or a comparable diameter wooden dowel, to add curl

to the segment of boxing strip, by drawing the strip

over the rod while applying finger (or thumb) pressure.

4. Visualize where the LID's boxing strips will be joined

4. Visualize where the LID's boxing strips will be joined

by forming, bending, shaping, then placing

across the top of the 'B', aligning the straight (uncurled)

segment across the corresponding portion of letter,

inserting the flange tab under the letter edge,

adjusting ends of strip segment with straight edge

of letter, and join in place.

Invert the assembly on a flat work surface to

apply fingertip pressure along the backside tab

to help secure the seam.

6. Position the curved portion of strip along the upper side

rounded edge of letter, adjust, taking care that

the end of strip aligns exactly at the end

of the curved edge (at the valley point)

and glue in place.

NOTE it will be helpful to invert the assembly in order

to apply fingertip pressure along the multiple tabs on

the underside to refine and secure the curve shape.

While the seam is still pliable/adjustable, work with

fingertips on the front side to adjust and correct

the curve seam.

7. Identify the next strip end by the tiny symbol

that corresponds to the first strip's end tab symbol.

Overlap the new strip's straight end edge across

end tab to perforation, adjust top to bottom to match

edges, then join seam.

8. Position the lower side curved segment along 'B'

edge, placing the end of multi-tab segment

at the transition angle where bottom straight letter

edge begins.

Adjust and align the strip edge with letter's edge,

then apply pressure to ensure secure and accurate joint.

9. Position, align and join the straight end section

in similar manner, taking care that end of strip

aligns at end of straight letter edge.

10. Locate and identify the final strip, overlap

and join end seam as previously done.

11. Apply adhesive to long straight edge and top end seam

tab, then position these along letter's corresponding

edges and join in place in one operation.

13. Prepare the interior opening TOP boxing strip

by bending forward at the cross perforations,

and bending back edge tabs.

NOTE that the upper opening boxing strip can be

identified with the 'T' symbol cut into the tab.

Use a rod tool to add tight forward curl at the multi

tab edges of strip, forming the strip by wrapping

around the tool and applying pressure by rolling.

NOTE: protect the narrow multiple tabs from tearing

by keeping them straight until the curling is completed,

then bending back into prepared position.

14. Form the interior strip into a rounded-ends

rectangular oval with face side inward, overlap

the end tab on the outward side and join the seam.

NOTE it may be helpful to insert a rod tool inside

the tube and under the seam being joined to provide

a "press-against" surface.

It may also be possible to press the tube into

a flattened position to apply fingertip pressure

along the seam to join.

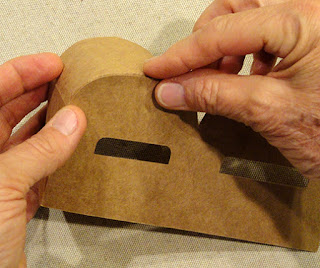

15. With tabs bent outward as shown here,

position the upper opening tube behind the guide form

corresponding opening (NOTE the arrow symbol

near top indicates 'UP' orientation) . . .

. . . to align tab edge perforations along

cut edges of opening.

Adjust edges to be as precisely aligned as possible,

then glue the edge seams.

16. Repeat the process to form the lower opening tube,

position and attach at lower opening edges of guide.

17. Position the guide shape on the inside of the LID

box, with guide openings aligned precisely behind

the main letter's corresponding interior openings . . .

. . . and glue in place, inverting onto a flat work

surface to apply fingertip pressure all around

opening tabs to attach guide securely inside LID.

18. Repeat the process to assemble the BASE

(reversed) letter 'B'. This image shows the front

BASE boxing strip being added to the lead straight

edge of the optional 'B' with trapdoor.

When needed to provide interior access

to allow for Bee 3D form wire insertion, the door

can be detached by simply tearing away where

a top "bridge" holds it in place.

NOTE: When building the BASE shape that will have

the support strut inserted to hold Bee wire, it will be

helpful to trim away excess BASE guide straight edge

so that only approx. 1/4" margin remains.

(This avoids build up that may affect how

BASE height matches up with LID height

when strut is inserted.)

Narrowed trimmed edge can still be positioned

and glued into place at 'B' BASE interior openings.

19. Position, align, adjust and attach BASE interior

openings assembly in place inside BASE main assembly.

20. If your project will use the interior (in BASE) strut

reinforcement, prepare it by bending the cross perforations

into zigzag shape, then tend side tabs back.

21. Use the end of the Bee's wire to poke through

the marked insertion points (preferable NOT to

create holes any larger than the actual wire fits through.

22. Position the strut down the straight "channel"

in the BASE, placing the top lead end into the corner

angle, then arranging so that the bend angles

touch or come close to touching the front wall

AND the interior opening walls. This will help the holes

align down the center, and line up under the top boxing

strip hole.

23. Make sure the trap door is open to assist

directing the Bee wire when inserted after letter box

is finished being assembled.

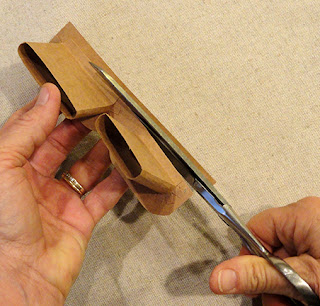

24. Fit the LID over the BASE, directing the LID interior

openings walls to the inside of the BASE interior

openings walls.

NOTE: this can be a tricky and time-consuming

portion of the assembly. If the fitting and closing

becomes to frustrating and difficult, one option is

use hand-scissors to cut down through the BASE

interior opening BOXING wall to perf line, allowing

the BASE interior openings to be opened more fully

to allow LID within.

Also, use a thin blade tool such as this spatula to

reach between the two forms to guide and adjust

as they fit together.

25. Once the LID and BASE are together fully,

flex the outer walls to apply quick-dry glue between

then immediately . . .

. . . cup the form between fingers and palms to

press inward to create a tightly fit, unified shape.

Repeat for the interior openings to attach those

walls to each other in similar manner (use tools

if necessary).

26. Position, align edges that match, and join

the honeycomb overlay on front of B main panel.

27. To attach the Bee stem through top, open

trap door and insert through outer top hole,

and feed through strut poked-holes.

When fully into place in desired extension

position, apply hot melt glue beads around

wire positions at strut holes, and hold

in place until cooled and wire is secured.

28. If side mount is preferred, determine Bee's wire

length and shaping, then position end on the side front

boxing panel and glue in place with hot melt glue,

then immediately position and assist attachment

with the attachment tab.

Here is the B Letter Box project with the BEE 3D

in place as side mount.

No comments:

Post a Comment