Trio

of crested, bottom-opening compartments connect

to form a “roll up” gazebo

shaped box which is side-tied

with 3/8” wide decorative ribbon.

Bottom nestles

into a scalloped circle “tray” base,

thickened for weight and sturdiness,

mirrored by

scallop edge peaked dome "lid".

Matched ribbon loop is strung

between top and bottom

which “tightens” into place with a 5/8” diam. painted

bead.

Accent shapes adorn outer and rolled-together walls,

dome edges and

panels, including the delicately detailed

checker panels, “hen” silhouette

cutout panel and fleur de lis.

This container carries well the “Three French

Hens” theme

for Twelve Days of Christmas gifting.

Combined unit measures

approx. 5.75” tall

x 4.89” wide x 4.89” deep which tied closed.

(Individual compartment

measures approx. 5.5” tall

x 3.25” across widest point x 1.875 across widest

point –

a five sided trapezoid.)

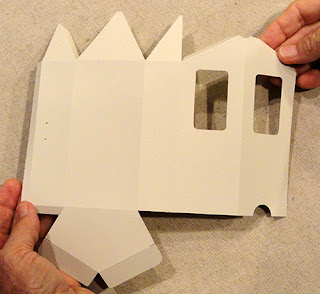

ASSEMBLY: 1. Identify and cut the shapes:

A box hulls: left, center, right

Base scalloped circles: B bottom layers (4);

C middle layers with ribbon slots (2);

D top accent layer with registration circles (1)

E bottom "tray" F tray accent strips (6)

G hull accent side panels (6)

H hen cut out accent panels (3)

I accent show-thru panels for hens (3)

J panel checker accents (3)

K gazebo "roof" L connector tabs (5)

M gazebo triangle whole panels (3)

with angled checker accents (3)

N gazebo triangle fleur de lis cut out panels (3)

with contrast show-thru triangles (3)

O gazebo roof rim accents (6)

P ribbon end anchor squares

Q interior double connector panels (2)

R interior accent panels (1 left, 1 right)

This project also requires: one 5/8" wooden bead,

painted in selected, coordinated color;

two 8-9" pieces of .375" wide grosgrain ribbon

for side ties;

and one 22" length of ribbon for top cinch loop.

the bottom 4 layers, one at a time, aligning scallop and

interior circle cut edges as precisely as possible,

on a flat work surface then flatten with a heavy object on top,

such as this thick book (place something else heavy on top too)

until thoroughly dried - up to a few hours or overnight.

the middle slot layer assembly on top of the base

the assembly.

Press under

flat weight until completely dry.

5. Prepare the "tray" shape by first disconnectingany remaining attached tab lower cut edges.

the outside surface of tray, aligning straight bottom edge

at perforation, scallop edges, etc. Press flat until dry.

7. Bend walls back to overlap short straight edge

over adjacent tab to perforation line, and join for

each side seam.

8. Prepare each of the box hull by bending back

on all perforation lines for panels, tabs and flanges.

NOTE that you can identify each unique box hullby locating the letter ID on the left side flange.

hen panel - position and attach checker accent

above base dash cuts; position and glue contrast

panel behind cutout

triangle panels - position and attach checker accent

on solid triangle panel above dash cuts;

position and attach contrast triangle panel

behind fleur de lis

each box hull, offset approx. .125" in from panel-defining

perforations.

11. Position and attach the narrow accent panels

on either side of center hull hen panel, and on panels

without the ribbon curved cut tab.

panels, disconnect the tiny bridge at center of cut

except leave the area that will be next to the ribbon

curve cut without glue. Position and attach accents . . .

. . . making sure that there is passage available

. . . making sure that there is passage available

through tab slot and pull through until only .5 to

.625" remains on inside of box hull. Glue in place

with quick-grab, secure adhesive such as

over the ribbon end to hide the ribbon end

and make inside of boxes neat.

Ribbon should be attached in this way to

both Left and Right box hulls.

13. Form the hull into a tube to bring straight side edge

to overlap flange to perforation line, adjust to align

tops and bottoms of adjacent panels, then join side seam.

Repeat for all three boxes.

NOTE it may be helpful to bend along the seam

perforation to apply fingertip pressure all along

to secure this seam completely.

Otherwise, the seam can be secured in its more "open"

position, especially with a pencil shaft or similar tool

placed behind the seam to press against.

14. At the top of the box, bend the side tabs inward,

then the side top wedge walls down into position

to align along the side tab perforation, and glue seam.

Repeat for both side seams.

15. Bend the center wedge panel into position

to align the angled side edges over the tabs at

perforation lines, adjust . . .

. . . and glue in place.

NOTE that access openings in interior walls

allow fingertips to reach inside to press behind

these seams during assembly.

Complete top seaming for all three boxes.

16. When boxes need to be closed, bend the wide tabs

at bottom inward as shown, then tuck sides into position . . .

. . . until bottom panel is flush.

17. In preparation to attach the three boxes into

their "roll-up" configuration, lay them out in order

L-C-R; also prepare the connector panels by bending

forward along the center perforation.

Position the left or right single interior accents on ends

with matched crest angle shaping;

position each connector double panel between

boxes.

18. Position and attach the single panels onto their

corresponding box faces, covering up the access

openings, with approx. .1 offset narrow margins around.

19. Position the appropriate half of the double panel

over the interior face to which it corresponds . . .

. . . folding the panel in half to align . . .

. . . perforated fold along the box panel edge,

with offsets at top, bottom and side as shown.

Glue this half of the connector panel in place.

20. Position the remaining half of the connector

over the adjacent box panel, adjust so that the box

perforated edges abut snugly, with margins matching

opposite box panel, and glue in place.

The two boxes are now attached with a "hinge".

21. Repeat for the final box to attach in same fashion.

This is how the roll-up box looks from the front.

The boxes ensemble can also be "rolled" as shown.

22. Prepare the roof shape by bending back on all

perforations for triangle panels, rim edge walls and

flange or tab.

23. Position and attach contrast rim edge walls.

24. Position and attach the accent panel assemblies

in alternating design type order, centered within

the perf-defined panel edges (narrow offset all around).

Press under flat weight if desired.

25. Form the shape into a dome by overlapping

straight edge across the flange to align at flange

perforation line, adjust top and bottom, and glue the seam.

26. Bend the two rims next to seam down to

complete the short seam with edge and tab.

27. Bend the five tab connectors forward slightly

at the center perf line. Position each behind

the other rim "seam" positions with bend aligned

at rim edges - rim side edges should abut snugly . . .

. . . and attach in place.

28. Begin the finishing of the project by threading

the ribbon loop length down and back up through

base center slots, then even out the ends.

Pull the loop away slightly from underside of base

assembly to apply strong adhesive dab (such as

the Fabri-Tack glue shown here), then pull the loop

into place again to attach within the underside's depression.

29. Thread ends through bottom of tray . . .

. . . and pull ribbon through as tray is slid into place

(bottom of tray to touch top surface of base assembly).

Before tray is snug in place, apply adhesive to underside

of tray without getting it on ribbon, and ease

tray into position, using the trio of positioning holes

in tray and on face of base to align, and glue the two

surfaces together. Consider using something

heavy to help press down tray edges while attaching.

30. Thread ribbon ends through dome center

opening, then . . .

. . . thread 'stop' painted bead onto ends

(this should be a snug fit).

31. With bead moved to within 1.5 inches or so of

ribbon ends, there should be enough space between

dome and tray base to wrap roll up box around

the ribbon, allowing the ribbon to pass through

the conduit formed when boxes are rolled.

Close the box into hexagon position and . . .

. . . fit bottom of box ensemble into tray.

Next position and fit dome over tops of

boxes, then . . .

. . . slide bead down to snugly hold the dome

in position, which keeps the assembly together.

Tie the side ribbon into knot and bow.

Here is the completed project.

Consider creating and using

the coordinated gift tag if packaging

the roll-up box - in cellophane, for instance -

for Twelve Days of Christmas (or other) giving.

No comments:

Post a Comment