Here’s a

fun and slightly spooky Halloween

wall or peg decoration. Large dimensional key

has

a hexagon shaft (cardstock wrapped dowel)

with cone added at top end, skeleton

cut out bit attached

near bottom, bulbous collar with end beads on

shaft,

and double-scroll bell at upper end.

Optional hanging ring also included

at top.

Bit, bell and top ring and collar “bead” rings are thickened

by

layering matched-edge or graded width shapes

(creating contour) then stacking

in each side of

center “base” shapes.

(Use flat weights to press glued-up

stacks

for best construction success.)

Create and attach “Halloween 3D

Medallion Lace Edge

with ribbon streamers near bottom of bell

for added flare.

Key measures approx. 13.25” long x 3.5” wide

x 3/4´deep when

fully assembled.

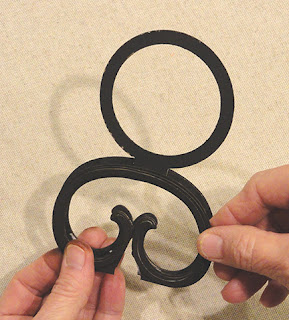

ASSEMBLY: 1. Identify and cut the shapes:

A shaft post wrap B shaft top cone

C top cone ring (5 shapes for layering & thickness)

D & E collar rings (5 shapes each for layering & thickness)

F collar ring

G skeleton bit with top tabs (left & right)

H & I bit layers for thickness (5 each left & right)

(NOT SHOWN: reinforcement tabs for bit joints - 2)

J bell middle layer with nib tabs

K base bell layers for thickness (2 sets of 3 each)

L middle bell layers for thickness (2 sets of 3 each)

M top bell layers for thickness (2 sets of 3 each)

N ring middle connector layers (2 for strength)

O base ring layers

(2 sets of 3 layers ea., including pairs of halves)

P middle ring layers

(2 sets of 3 layers ea., including pairs of halves)

Q top ring layers

(2 sets of 3 layers ea., including pairs of halves)

2. Prepare the many "layered-for-thickness" shapesthat compose the bell, ring, bit and throat rings

so that they can be glued-up and drying for the time

required before construction of the whole key progresses.

A) separate the three layers each of bell base, middle

and top layers for front; do the same for the back assembly.

B) stack and glue up the base layers, taking care to

B) stack and glue up the base layers, taking care to

align ALL cut edges as precisely as possible,

and to avoid warping or curling caused by liquid glue,

place the glued stack under a flat heavy object such as

this thick book (possibly with other heavy objects on top)

and leave in place until dry -

this may require hours or overnight.

. . . and top - to form the front contoured assembly,

centering the narrower added layer within edges of

layer underneath (middle bottom straight edge is only part

of the base layer; use the other areas for centering).

E) repeat for the back bell assembly

F) position one bell contour unit on top of the bell middle

layer with nib tabs, with outer edges (except nibs)

aligned precisely all around.

G) repeat step F on the back of the bell middle layer.

Press the completed bell contour assembly flat until dry.

H) stack, align edges and glue layers for front & backlines as shown - outer line as "mountain" fold,

and inward line as "valley" fold.

J) position each bit stack on corresponding bit base,

matching side, bottom and interior cut edges precisely.

Press flat until thoroughly dried.

K) layer the neck or collar rings into 3 respective

stacks with all edges aligned and glue together.

Press until dry.

L) layer and glue together the middle connector layerrings (2), the ring base shapes (two sets of 3 ea.),

the ring middle shapes (two sets of 3 ea.),

to the assembly for bell shapes in step D above,

centered all around within the edges of the ring below.

bending back on all long vertical perf lines for

flange and panels. Also bend back on bottom hex "lid"

as a pressing form, overlapping the straight panel edge

across the opposite flange to perforation line,

and glue in place. NOTE it will be necessary to work

fingertip pressure and make adjustments all along

the shaft edge to ensure the tube is tight and not twisted,

and seam secure.

the bottom end even with tabs and "lid" - folding them

down at edge of dowel original cut end. Hold in place . . .

. . . until the straight opposite top end can be

. . . until the straight opposite top end can be

accurately marked with a pencil line all around.

Remove dowel and cut just shorter than

the graphite of the cut line.

in place to end of dowel.

(Also, apply glue inside ends of tube before

it is inserted to further attach dowel to tube.)

7. Prepare the bulb collar shape by bending back

on all center perforation lines for panels, side tab,

wedge tabs and angled end panels; bend forward

at each set of end tab perforations.

8. Form the collar into a tube to overlap straight panel

edge to opposite tab perforation line, and glue seam.

9. Bend the angled end panels inward to align

the straight edge across the adjacent reg. or

wedge tab's perforation line, and join the seam.

Repeat for all end seams - both ends.

NOTE that the narrowness of the tube may make it

necessary to insert a rod-like took such as the handle

of this spatula tool inside tube end and behind the seam

to provide a "press-against" surface to secure seam.

10. Position and insert the top of the shaft into

the collar tube . . .

. . . and slide into place approx. 2" down from top edge.

NOTE that the tabs should each align down the center

of one of the six faces of the shaft wrap.

Apply glue under all end tabs and attach to shaft.

11. Slide one collar ring over each shaft end and

slide into position snugly against the collar's bulbous

shape - over the tabs, at tab perf lines, and glue in place.

12. Slide the cone ring over the top end of shaft

(where it will await final positioning).

13. Position the front and back bit assemblies

back-to-back, align side and bottom edges and cutout

edges, and glue together; top bent tab panels

must remain unglued. Press and allow to dry thoroughly.

14. Position the flanges around the shaft at one

hexagon angle of shaft wrap - this edge becomes

the more-or-less bottom angle of the shaft,

though slightly forward of center, due to the attachment

method for bit.

15. Bend each of the two reinforcement tabs

as "valley" folds, then position one on front and

one on back, centered across the face of skeleton bit,

with perforation line at inward bit perf line, and

glue each in place. (These tabs will strengthen

the bit-to-shaft connection.)

16. Complete the bell and ring assemblies by

applying glue to the bottom connector tab of

middle ring layer, then . . .

. . . positioning it on top at center top of middle bell

layer with nib tabs. NOTE that the suggested

continuation of the ring portion should NOT overlap

the bell shape's top edge.

17. Layer one bell contour assembly onto the front

of the bell middle layer, enclosing ring's connector

tab, and glue in place. Repeat for second assembly,

attaching it to back of bell middle layer. Press until dry.

18. Position and attach the ring contour assemblies

to front and back of middle connector ring layers.

Press until dry.

19. Prepare the shaft top cone by bending back

on all perforation lines for tabs and wedge panels.

20. Form the shape into a cone, then overlap

the straight side edge across the opposite tab to

perforation line, and glue seam. Insert the end of

a tool handle such as the spatula handle, placed

behind the seam, to help with applying pressure

and securing seam.

21. Orient the cone so that the tab slots are at top

and bottom positions, then, after applying glue to

thickened edges of triangle cutout

at center bottom of the bell/ring contour assembly,

insert cone into that cutout. . .

. . . and slide into position assisting the nib tabs to

fit into the cone slots. Hold in place until glue grabs,

,double-check for desired alignment along

belle's face plane, then allow to dry thoroughly.

22. Orient the shaft with bit so that the place of

the bit is close (half of one hexagon rotation away)

from being on the same place as bell/ring assembly.

Apply strong glue to the top of shaft, and glue

to the underside of cone tabs, then insert top shaft end

into the bottom of cone, fold cone tabs down, centering

each within one shaft hexagon face, and secure in place.

Hold until secure, then allow to dry thoroughly.

23. Apply glue to the bell bottom "flat" thickened edges

where the bell ring will touch, then slide the ring up

until it touches the bell edges. Apply pressure

until ring attaches - assisting with connection

and strength of attachment - and allow to dry thoroughly.

Here is the completed dungeon key with hanging ring.

Decorate with a cluster of ribbons as shown . . .

. . . or with pleated spiky lace October 31st medallion.

No comments:

Post a Comment